The FOA

Update Page covers all the new technology and

applications we covered in this newsletter in 2018-19. Now you

can review all that new tech at once.

The FOA

Fiber FAQs Page (FAQs = frequently asked questions)

gathers up questions readers have asked us (which first ran

in this newsletter) and adds tech topics of general

interest.

This

months "Good Questions" has some unique

questions from our readers.

Fiber

Optic Cable Plant - The Finished Product

This month,

FOA has received inquiries from several sources that all deal

with the same subject - what is involved in the specification

and acceptance of a cable plant at the end of a installation

project. And what are reasonable specifications for a cable

plant.

FOA has a lot of documentation on a project involving

designing and installing a cable plant in the FOA Online Guide

and our Textbooks, but the acceptance process is relegated to a

few paragraphs. Let's look at a project and include a few links

to FOA tech documents in case you want to investigate further.

The Project "Deliverables"

Fiber optic projects start with a design

that creates project

paperwork - the scope of work (SOW), request for proposal

or quote (RFP/Q) and a contract with the builder/installer. A

"Scope of Work" document is created by the initiator of a

project to describe the work to be performed or the services to

be provided by a contractor. It describes tasks to be performed,

directs methods to be used, and defines the period of

performance. It should contain design and performance

requirements. A scope of work for communications cabling or

fiber optics may be part of a larger building project document

that is based on a standardized format called "MasterFormat"

in the US and Canada.

A well written scope of work can do more for the success of a

contract than any other part of the contracting process. A good

scope of work is clear, complete, and logical enough to be

understood by the respondent and the university personnel who

will administer it. Because it describes the details of

performance, it is the yardstick against which the respondent's

performance is measured. That is why the user's requester,

contract administrator and/or subject matter expert should be

the focal point for developing the scope of work.

What we are discussing here is the final product - the

"deliverables" - that define the final product that the end user

expects to have when the installation is complete and ready to

use, or in some cases already has the communications equipment

installed and operating. Of course the deliverables include the

physical cable plant, but also must include full documentation

and test results, and maybe even a warranty.

Cable Plant Specifications

What are reasonable specifications for a cable plant. We've

often heard stories of specs that are too stringent and others

too lax. Since specifications for the installed cable plant are

up to the person specifying the cable plant, they may be

confusing because very few standards exist for the design and

specification of the cable plant. OSP networks have

traditionally been specified and owned by sophisticated users

who have a history of what specs can be expected. Premises

cabling systems tend to use component specs from TIA or ISO/IEC

standards that are generally too lax, much higher than what

should be expected.

Let's do the executive summary. The cable plant should be

specified for loss using a loss budget. Network speed may

dictate specifications for component types or bandwidth. Here is

a summary of FOA's "reasonable specs" to use for cable plant

loss budgets. Below we'll get into testing with loss budgets

based on those specs.

OSP

Fiber: G.652 attenuation 0.4dB/km at 1310nm, 0.25dB/km @ 1550nm

Splices: Average 0.1dB, reject @ 0.2dB

Connections: Average

loss 0.3dB, reject @ 0.5dB, Reflectance better than -40dB.

Long haul fibers like G.654 will have slightly better

attenuation specs, ~0.2dB/km.

Premises

Fiber:

Multimode OM3/OM4 attenuation 3dB/km @ 850nm, Bend

insensitive fibers

Singlemode

OS1/OS2 attenuation

0.5dB/km @ 1310nm, Bend

insensitive fibers

Splices: Average 0.3dB, rare in premises

Connections: Average

loss 0.5dB, SM reflectance better than -40dB.

Cables, of course, are specified according to the

requirements of the project and it's physical

locations.

Documentation

The final documentation delivered to the customer must be

comprehensive, with full route information including GIS

(geographic information system) data on the location of the

cable and every component - cables, manholes/handholes, splice

locations and full descriptions, plus test data. The physical

component and location information is obvious, but what is not

is test data, which we elaborate on below.

What's sometimes missing, based on inquiries we get from end

users, is understandable documentation. Managers who may not be

familiar with fiber optics can be given reams of documentation

which they are expected to use to sign off on a project. There

are many stories about problems at this stage: signing off on a

data center installation where all 4,000 connectors were

failures, getting test data on a OSP network where every OTDR

test was the same, you get the idea. Before signing off on a

project, someone who knows fiber optics and was involved in the

project should review the documentation and test data and verify

that it is correct and valid.

Cable Plant Test Data

To prove the cable plant was installed properly requires test

data, of course. During the design phase, loss budgets

calculated for each cable run should provide an estimate of the

expected loss of the fibers in each cable link to compare to

actual test results.

Short fiber

optic premises cabling networks are generally

tested in three ways, connector inspection/cleaning with a

microscope, insertion loss testing with a light source and power

meter or optical loss test set, and polarity data, meaning that

the routing of fibers is confirmed so that when connecting

equipment the tech can identify fiber pairs for transmit and

receive. Polarity testing generally can be done with a visual

fault locator to confirm that fibers are connected per the

documented cable diagrams.

Outside plant (OSP) testing is more complex. If the cable plant

includes cables concatenated with splices, it's expected to add

OTDR testing to the connector inspection, insertion loss and

polarity testing. If the link has passive devices like FTTH

splitters or WDMs, those need to be tested and documented also.

There is one thing that whoever is reviewing the data - and

going back to the design phase, whoever writes the test

specifications based on the loss budgets in the first place -

needs to understand: none of these are absolute numbers.

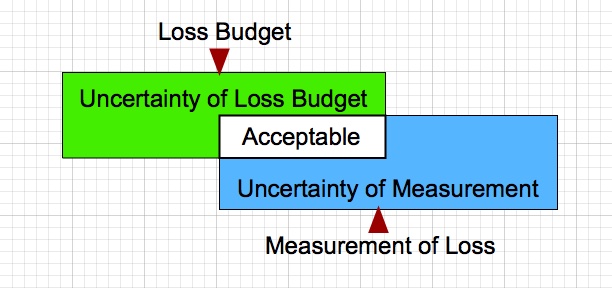

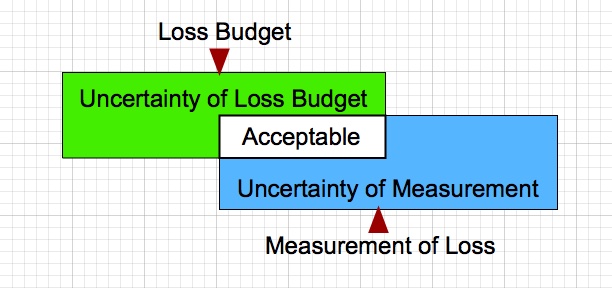

The loss budget which is created early in the design

phase estimates the loss of the cable plant based

on estimates of component loss and therefore is

not an absolute number, but an estimate to be

used to compare to test data.

Test data is created by instruments and related components that

make measurements which have measurement errors.

There are always factors in making measurements that cause

the instrument reading to be inaccurate - only an

approximation of the real value - and the real value is

unknowable because of measurement errors. (If you are curious,

look up the Heisenberg uncertainty principle.)

Let's

look at this symbolically:

The loss budget is not exact, nor is the testing, so

there is a range of measurements that should be

acceptable. Some judgement is needed to determine if a

particular fiber is acceptable.

In our experience, those two factors cause more stress between

managers and installers than just about any other factor in a cable

plant project. Consider these examples of the issues with loss

budgets and testing errors.

OSP Cable Plant

Here is the situation a CFOT found themselves in when they

called the FOA. They were an 30+ year experienced splicer with

a half-million splices of experience. A customer wanted to

specify a long cable plant (~50 miles/80km) with splices that

averaged 0.05dB and any splices above 0.15dB was not

acceptable. Testing of the splice loss would be done with an

OTDR with bidirectional measurements and averaged.

What

made this call particularly interesting is this tech had some

real world data, the kind you do not see often. On a past job,

he had spliced a ~60 mile (100km) 288 fiber cable plant at 18

splice locations, that's 5,184 splices. His test records

showed that 60% of the splices were in the range of 0.02 to

0.08dB and 40% were in the range of 0.08 to 0.15dB. Only 17

splices were over 0.15dB.

The

customer noted that the

manufacturer

of the splicer used by the tech quoted a splice loss

capability of 0.02dB, so a field spec of 2.5 times that should

be easily achievable in the field. What the customer did not

understand was that 0.02dB

spec for the splicer was data taken in a laboratory on a

new or perfectly set up machine. The splices were made by

breaking a fiber and splicing it back together. Every

splice used in determining the splicer capability used

identical fibers - they were the same fiber.

In the field, when splicing cables together, the

environment is not like a lab. Machines are used to splice

thousands of fibers. The fibers in the cable can be from

numerous production runs and will have variations in mode

field diameter (MFD) and geometry. Assuming a long haul

network like this one is using G.654 fiber, we can look at

the ITU standard for G.654 fibers and we find these

specifications:

Mode Field Diameter: 9.5-10.5microns

Core Concentricity Errors: 0.8micron

That variation in fiber geometry and MFD can produce a

real difference in splice loss that will be directional.

That difference can be 0.05 to 0.1dB. That is independent

of how well the splicer can align and fuse fibers. Even if

aligned perfectly

and spliced perfectly

the differences in the fiber will cause directional splice

differences - higher in one direction, lower in the other.

The can be a 0.20 to 0.25dB difference in directional

splice loss when measured by an OTDR

caused by MFD variation in the fibers

(data from Corning ap note AN3060). This is something

which many techs are familiar with, but that method of

bi-directional testing merely removes the OTDR scattering

error and gives the average of loss from each direction.

It can't compensate for the actual directional splice loss

caused by the difference in MFD. Let's repeat that:

Bi-directional OTDR testing removes the OTDR error caused

by differences in fiber MFD or backscattering, but cannot

compensate for the actual directional difference in

splice loss caused by the difference in MFD.

Back to the customer's spec. They wanted an average splice

loss of 0.05dB and no splices over 0.15dB - which was

unacceptable. Using some math, we can analyze the data the

tech had from the prior 60 mile (100km) job. The average

splice loss on that cable plant was ~0.07dB. And only 17

were larger than 0.15dB, so the reject rate would have

been 0.3%.

If we compare the results of that job to the specs the

customer wants on the new job, the difference would be

0.02dB/splice at 18 splice points. The total loss

difference in the 60

mile (100km) cable plant would be 0.02dB X 18 or

0.36dB - and that is on a

60 mile (100km) run where the fiber loss

is 0.20dB/km X 100km or 20dB. And the loss

of the original 18 splices was only

~1.33dB! The difference is negligible and

the measurement uncertainty of the OTDR

test of end-to-end loss is much bigger

than the difference.

Premises Network

In premises fiber optic networks, the TIA standards allow for

connections to have a loss of 0.75dB - that is two connectors

mated to create a connection. A

fiber optic connector has no loss, per se, because it is

not being used. When in use, it is mated to another

connector creating a joint between two fibers, and that

joint is what has loss - a "connection" loss.

That number has been in the standards for at

least 30 years, but even then typical connectors with ceramic

ferrules were much better than that. That 0.75 dB loss was

needed for early connectors like SMAs and Biconics, so it

became the standard, Later, although everyone knew that the

typical ST, SC, FC and then LC connector was much better, the

industry saw the introduction of array connectors (MPOs) where

the 0.75 dB loss was needed, so rather than have different

values for single fiber and array connectors, it was left at

0.75dB.

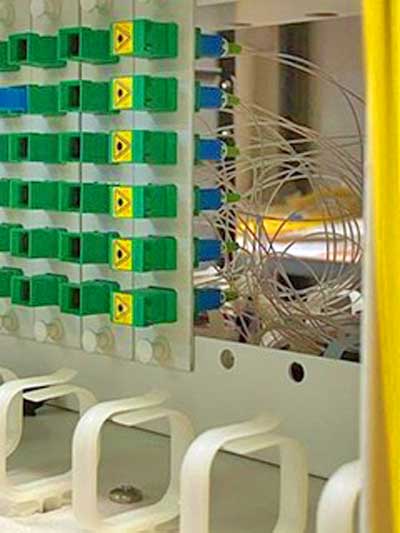

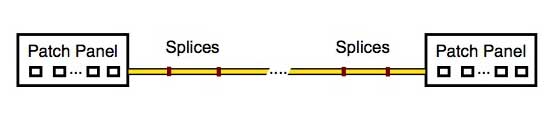

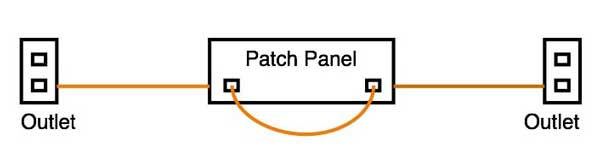

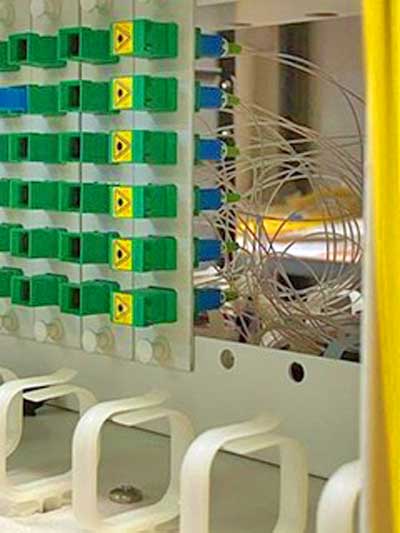

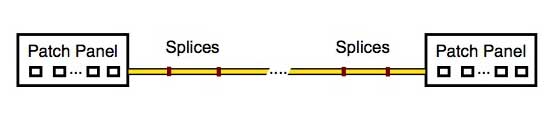

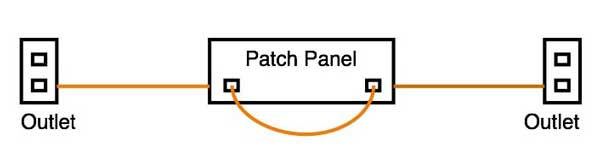

If you do a loss budget for a premises network with an

intermediate patch panel like the one above, your loss budget

would include 4 connection losses, the two in the patch panel

and the ones in the outlets at each end where you connect the

patchcords to the LAN gear. The 4 connection losses using the

TIA model would allow a loss budget for connections of 4 X

0.75dB = 3.0dB. But if typical connections

are less than 0.5dB, you could have 3 connections

at 0.5dB and 1 connections

could be 1.5dB. If you had good connections

of 0.3dB, that fourth connection

could be 2.1dB!

When we look at fiber losses, TIA allows fiber

losses of 3.0 to 3.5dB/km at 850nm for

multimode fiber. Actual fiber is now less than

3dB/km, but since links are typically short,

~100meters, the error due to fiber being

better than the standard is only tenths of a

dB. That is too small to matter.

If our link above is 100m, the loss budget

using TIA numbers would be:

Fiber 0.1km X 3.0dB/km = 0.3dB

Connectors 4x 0.75dB = 3.0dB

Link Loss Budget = 3.3dB

With more realistic numbers, say 0.5dB connections, it would

be:

Fiber

0.1km X 3.0dB/km = 0.3dB

Connectors 4x 0.5dB = 2.0dB

Link Loss Budget = 2.3dB

And with really good connections,

say 0.2dB:

Fiber

0.1km X 3.0dB/km =

0.3dB

Connectors 4x

0.2dB = 0.8dB

Link Loss Budget =

1.1dB

That's a 2.2dB difference in a 100m

multimode network; that's a big

uncertainty! What would we choose for a

GO/NO-GO loss? Our judgement would be the

link should be under 2.3dB

Now

what happens when we test this link?

We use a LED test source at ~850nm, a meter calibrated at

850nm reading in dB, and two reference cables to make a

double-ended test. In a short link like this the cause of

measurement uncertainty is the loss of the connections.

Variations in modal fill from the test source and launch cable

can result in 0.2dB variations, which has resulted in an

international standard for mode fill, called "encircled flux"

which most multimode test sources today meet, but early

sources are unknowns and add to the uncertainty, The launch

and receive cables also add to the uncertainty, since fiber

standards allow up to +/-5% variation in core size, which can

cause loss variations at connections depending on the

direction of the light.

There are so many variables in making an insertion loss test

of multimode fiber that they fill a giant table in the FOA

page on "metrology" or the science of fiber optic

measurements. The generally accepted number for uncertainty of

this kind of measurement is ~0.2 to 0.5dB.

So exactly what is a acceptable test result for this fiber

link? If we measure a loss of 1.5dB, no question it passes. If

it measures 3.5dB, that's certainly a problem. But what if it

measures 2.5dB? That's 0.2dB higher than the loss budget

estimate we used, but we know the measurement is uncertain by

+/-0.2

to 0.5dB, and 2.3dB is within the uncertainty of the

measurement. It's probably OK.

Why

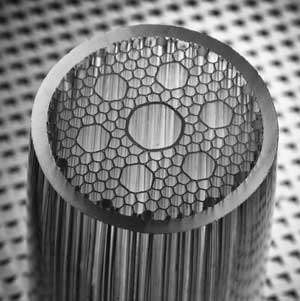

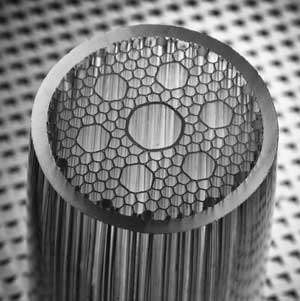

Would You Want A "Hollow Core" Fiber?

OFS Hollow Core Fiber Preform

OFS has just introduced AccuCore HCF Optical Fiber Cable, the

world's first terrestrial hollow-core fiber (HCF) cable

solution.

Why?

Fiber optics is often described as "sending signals at the

speed of light." But typical fibers are made of glass with an

index of refraction of ~1.5, so light travels at the speed of

light in a vacuum, c, divided by the index of refraction of

the medium it is traveling in, here 1.5, or c/1.5 = 0.67c -

2/3 the speed of light in a vacuum. That's about the same

speed as electrons travel in twisted pair cables and much

slower than in coax cables where the speed approaches 0.9c.

So why hollow core fibers? Latency.

Light travels about 50% faster in a hollow core compared to a

solid silica core of conventional optical fiber. Consequently,

light transmitted in a hollow-core fiber arrives 1.54

microseconds faster for each kilometer traveled compared with

conventional optical fiber.

The AccuCore HCF Optical Fiber Cable solution is based on

proven hollow-core fiber technology and includes

indoor/outdoor cable and termination with standard connectors,

which are fusion spliced to the patented photonic bandgap

hollow-core fiber. OFS also offers installation services and

both passive and active component selection to meet customer

requirements. AccuCore HCF optical fiber cable has been

successfully deployed, carrying live traffic in several

networks. Read the press release here.

Applications include:

High-frequency trading

High-performance computing

5G X-haul mobile networks

Intra-data center interconnection

Read

more.

When Is

A Dust Cap Not Filled With Dust?

When it's a

"CleanAdvantage(tm)" cap on a Corning Edge(tm) factory

terminated cabling system.

"Corning

understands the value of clean connectors to ensure optical

performance. So much so that we have developed a new factory

cleaning and sealing process, Corning® CleanAdvantage™

technology, to ensure a pristine end face upon first use for

all our EDGE™and EDGE8® solutions.

Thus, saving you as the installer time and money during the

initial installation. So go ahead and uncap that

CleanAdvantage connector so that you can connect with

confidence."

Read

More.

Don't

miss this Corning trivia about fiber - 3 times stronger

than steel.

Innovative

Microscope Awarded US Patent

Ed Forrest

of Fiber

Optic Precision Cleaning has been granted US Patent No.

10578847 for his innovative widefield microscope for fiber optic

connector inspection. Unlike other fiber optic microscopes that

closely inspect the end of the connector ferrule, this

microscope looks at the whole ferrule and the receptacle to

determine what else is dirty besides the end of the ferrule.

Dirt in the connector body is often the source of the dirt on

the end of the ferrrule, so it needs cleaning also. This

microscope should, of course, be used in conjunction with a

normal 100-400X inspection microscope.

Fiber

Optic Precision Cleaning also offers several excellent

books, whitepapers training on fiber optic connector inspection

and cleaning.

Is

There A Standard For Fiber Optic Installation?

Another

question we get often is "Is there a standard for fiber optic

installation." The answer is yes, but not from the usual

standards groups you might think about. Over 20 years ago, the

National Electrical Contractors Association (NECA) asked FOA to

help create a standard for installation. That standard,

ANSI/NECA/FOA-301 has been updated three times already and is

about ready for another update.

Unlike most of those groups who charge you a fortune for

standards, FOA covers the cost so ANSI/NECA/FOA-301

is available free from FOA.

Download

your free copy of ANSI/NECA/FOA-301

here (PDF)

More Questions and Answers from our

readers below.

Safety

Leader Magazine

Safety Leader, a new quarterly magazine, informs and educates

electrical contractors on safety from various angles—electrical,

workplace, PPE, regulations, leadership, line work, NFPA 70E,

and more. Safety Leader is bundled with ELECTRICAL CONTRACTOR in

February, May, August and November. To receive Safety Leader subscribe

to ELECTRICAL CONTRACTOR magazine here or subscribe

to the ELECTRICAL CONTRACTOR newsletter here.

Conference

On Damage Prevention Cancelled But Goes Online

CGA

811 Excavation Safety Conference & Expo, the

premiere international event in the damage prevention

industry, was supposed to be March 24-26 but was cancelled

due to the coronovirus. Next year's program will be in

Tampa.

FOA was supposed to participate with a talk about New

Installation Techniques For Fiber Optics and participate in

a panel with members of the North

American Telecom Damage Prevention Council to discuss

the issue of protection fiber infrastructure from damage.

The conference organizers are having a several "Digital Days

of Education" so hopefully you can soon watch the sessions

online.

The magazine, dp-Pro, sponsor of the conference, has also

published it's latest issue with an article by FOA on "New

Construction Techniques in Fiber Optics" and a overview of

the FOA. You

can read the magazine here.

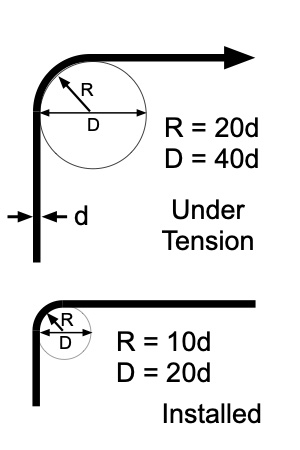

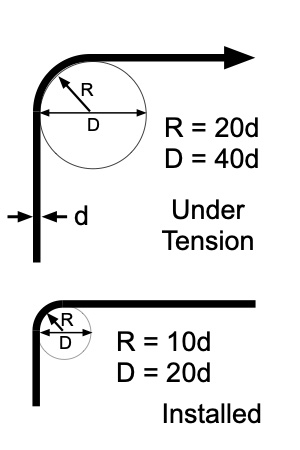

Bend

Radius (Quick Tutorial)

All

fiber optic cables have specifications that must not be

exceeded during installation to prevent irreparable damage

to the cable. This includes pulling tension, minimum bend

radius and crush loads. Installers must understand these

specifications and know how to pull cables without damaging

them.

The normal

recommendation for fiber optic cable bend radius is the minimum

bend radius under tension during pulling is 20 times the

diameter of the cable. When not under tension, the minimum

recommended long term bend radius is 10 times the cable

diameter.

Note: Always check the cable specifications for cables you are

installing as some cables such as the high fiber count cables

have different bend radius specifications from regular cables!

Under

tension (top) and after pulling (bottom)

Bend radius example: A cable 13mm (0.5") diameter would have a

minimum bend radius under tension of 20 X 13mm = 260mm (20 x

0.5" = 10") That means if you are pulling this cable over a

pulley, that pulley should have a minimum radius of 260mm/10" or

a diameter of 520mm/20" - don't get radius and diameter mixed

up!

Why

is it important? Not following bend radius guidelines can lead

to cable damage. If the cable is damaged in installation, the

manufacturer's warranty is voided. Here is what one

manufacturer's warranty says: "This

warranty does not apply to normal wear and tear or damage

caused by negligence, lack

of maintenance, accident, abnormal operation, improper

installation or service, unauthorized repair, fire,

floods, and acts of God." And their specifications call

our the minimum bend radius as "20 X OD-Installation, 10 X

OD-In-Service."

Some

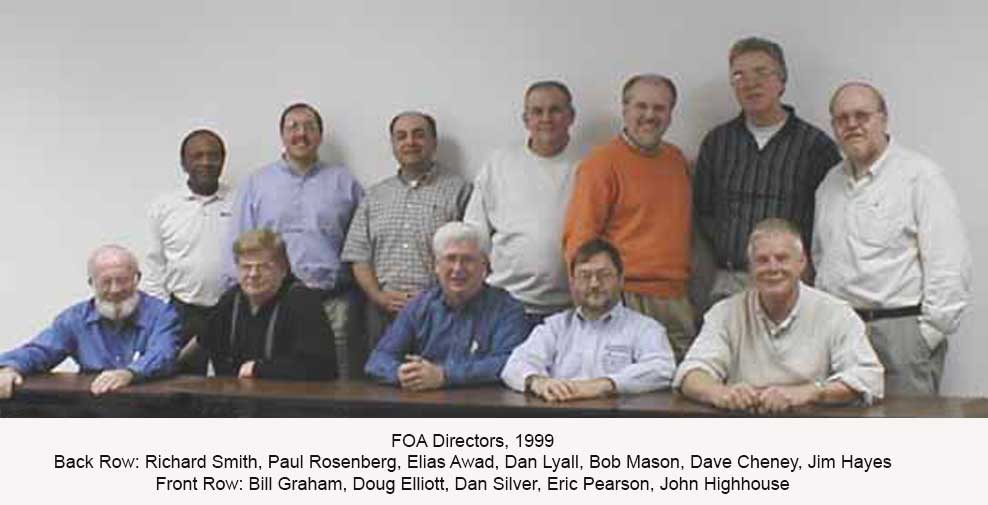

FOA Founders Still Active

Recognize

Anybody Here? This

is the FOA Board of Advisors 20 years ago, meeting to work on

FOA certifications.

Those listed below in BOLD are still active teaching and

working with FOA.

Who Were The FOA Founders?

Jim Hayes, President of FOTEC Inc. Pioneering fiber optic

entrepreneur in test equipment and trainer who was trained in

physics/astronomy. Author of many EIA/TIA standards and the

instigator of the NBS/NIST fiber optic calibration program.

Creator of the Fiber U training conferences. Author of ten

textbooks, hundreds of technical articles. Current FOA

President.

Eric Pearson, Pearson Technologies. Trained by Corning in

the 1970s, considered an industry expert on termination and

splicing, training since the early 1980s. Active FOA

Instructor.

Dominick Tambone, Engineer, Automatic Tool and Connector, fiber

optic termination and installation, training since the early

1980s. Contractor and Active

FOA Instructor.

Bill Graham, Mississauga Training

Associates, Toronto, ON, CN. Background in utilities, military,

metropolitan fiber optics, training since the early 1990s. Current

FOA Director.

Prof. Elias Awad, Wentworth Institute, Boston, MA. Started one

of the first fiber optic academic programs in the engineering

department in late 1980s. Creator of NSF program “Fiber Optics

For Engineering Technology” (NSF#9353997).

Prof. John Highhouse, Lincoln Trail College, Robinson, IL. Head

of telecom training program, started teaching fiber optic

outside plant construction in late 1980s. Masters in Education,

specialty testing.

Paul

Rosenberg, writer and technical trainer

Dan Silver, Product Specialist, 3M Fiber Optics, trainer and

applications. The man with the idea to create the Fiber U

training conferences and active FOA member.

Eric Loytty, Field Engineering, Corning/Siecor, applications and

training.

Bob Mason, Product Manager, Network Systems, Panduit,

applications and training.

Doug Elliott, IBEW Instructor, Toronto, ON, CN. One of first

IBEW apprenticeship instructors to teach fiber optics.

Tom Collins, Northern Kentucky Technical College,

Professor. Techtricians, Owner/instructor. Current FOA

Director.

Dan Lyall, Project Engineer, Lockheed Martin, applications and

training.

James H. (Jim) Davis, Program Director, Navsea 56ZC, Navy fiber

optic standards.

Dave Chaney, Disney, Network Manager

Tony Beam, Tyco/AMP, Product Manager

Richard J. Smith, FOTechnologies, Technican/Instructor

Trevor Conquest, Conquest Communications, Brisbane,

Australia, fiber optic training.

Training

In The Frozen North

Bill Graham (lower left above with the white beard) lives near

Toronto and has probably trained half of Canada in fiber optics.

Bill sold his company, Missisauga Training, several years ago to

another active Canadian who

took over the training but Bill is still active as a FOA

Director and promoter in Canada. Bill is famous for training in

the Frozen North, still in competition with Ian Gordon Fudge of

Fiber DK in Denmark to see who has trained closer to the North

Pole. Bill always sent us photos from his trips, like these:

Netcom Training and maybe one of Bill's students near the Arctic

Circle

And yes, getting there was half the fun. That plane on the

right is a DC-3, probably more than 70 years old!

Bill is also an expert speaker, first a learning

from Toastmasters

and

then becoming a leader of the organization. He's written a short

guide for speakers that we recommend to everyone who has to get

up before a crowd and speak. You

can get "So You Are Presenting" by Bill Graham on Amazon.

FOA

will be 25 years old in July - watch for more articles on FOA

history.

Worth

Reading - News Summary

Each

month we read hundreds of newsletters and online articles.

These are the ones we think you will find "worth reading."

ISPs

Raise Speeds and Suspend Data Caps in Response to the

Coronavirus Pandemic - Consumer Reports.

Coronavirus

School Closings Expose Digital Divide - US News

Understanding

The True State Of Connectivity In America - 65% of US

counties receive broadband speeds below industry reports.

CityFibre

closes FibreNation acquisition - UK - The addition

of the new fiber assets has led CityFibre to raise its fiber

to the premises (FTTP) deployment plans from 5 million to as

many as to 8 million premises. From Lightwave.

Why

Businesses Need Fiber Connectivity, from Spectrum CATV.

Yes, it's a sales pitch, but they make good points and it

indicates they are serious.

DIRT

Report On Damage To Utilities

Common Ground Alliance (CGA) annual DIRT report provides a

summary and analysis of the events submitted into CGA’s Damage

Information Reporting Tool (DIRT) for the year 2018. The

complete report is available for download

here. In addition, there is an interactive

dashboard that allows users to filter the data

more by factors contributing to damages.

Cedar

Falls, Iowa is monitoring a bill in the Iowa State House

that could threaten their municipally owned and operated

broadband utility network. Senate Study Bill

3009, introduced by Sen. Dan Dawson, R-Council Bluffs is

ibacked by commercial service providers.

Structured

Cabling News - a website and weekly newsletter

about cabling.

Self-Driving

Trucks Hit The Roads in Texas. Waymo (Google)

tests their vehicles in Texas.

Utilities

Team Up on Plans to Run Fibre Through the Sewers

(Again!)

Five water utilities have teamed up with infrastructure firm SSE

Telecoms on plans to lay fibre optic cables in the UK’s

sprawling network of waste water pipes. We first reported on

this proposed method for fiber installation in the FOA

Newsletter in 2012! It has not exactly taken off!)

The

Internet Master Plan for New York City.

The New York City Internet Master Plan is a comprehensive

framework for the infrastructure and services that provide

connectivity to New York City residents and businesses.

This Master Plan will guide City actions and

public-private partnerships to transform New Yorkers’

access to this essential infrastructure for generations to

come.

Corning

Has Removed The "Dust" from "Dust Caps."

Corning "CleanAdvantage(tm) Edge cables have factory cleaned

connectors and caps to keep them clean.

Fiber

Trivia From Corning.

Why

understanding PoE now is crucial for electricians -

To ring in the new decade, IDEAL Networks is urging today's

electricians to master new skills and equipment to cope with the

growing use of PoE in intelligent lighting applications.

Smart

City Projects: Smart city initiatives are underway

across the country. But they face funding and technology

challenges. Many cities want to upgrade infrastructure to

improve resident experience, safety and to generate revenue.

Cloud

Computing Is Not the Energy Hog That Had Been Feared

- The digital services churned out by the world’s computer

centers are multiplying, but their energy use is not, thanks to

cloud computing, a new study says.(NYTimes)

Data

Centers’ Impact on Climate Change May Be Overblown -

Researchers argue that new technology and greater efficiency

could offset energy demands (onezero)

The

Future Of Work Is Skills - So Stop Worrying About Degrees

- The

reality is the future of work is about skills, not just degrees.

(FOA Newsletter Feb 2020)

Want

a White-Collar Career Without College Debt? Become an

Apprentice (NYTimes)

Apprenticeships probably began with the first jobs, where

young people work under experienced craftspeople to learn a

trade. In the last century, they became more organized under

labor unions like the International Brotherhood of Electrical

Workers, one of the FOA's oldest and biggest approved school

systems. Today, apprenticeships are expanding as young people

look at viable alternatives to loading themselves with debt

while attending college.

The

job market is hot. So why are half of U.S. grads missing

out?

VIAVI

Books On Fiber Optic Testing (2 volumes) - They're back!

Besides the

FOA reference materials, two JDSU/VIAVI textbooks, Reference

Guide to Fiber Optic Testing, Volumes 1 and 2, were used

as references for some of the FOA courses and are recommended

for instructors and students. The books are available from VIAVI

as eBooks and the everyone should download them and recommend

them to others.Download yours now. Volume

1. Volume

2. Viavi Books

50th

Anniversary of The Development of Low Loss Fibers A

history of the development of low loss fiber, a fascinating

story by Jeff Hecht on the OSA (Optical Society of America)

website.

How

OFS Makes Fiber

Interesting YouTube video on how fiber is made. Perhaps a little

too much "show biz" but fascinating. If you have ever seen fiber

manufacture, look at this video. You will be amazed at how big

preforms have become!

How

Nexans Makes Copper Cables - compare the process to

fiber - don't most of the machines look similar?

The

True Cost of Telco Damages (what backhoe fade or

target practice can cost)

Rural

Electric Cooperatives: Pole Attachment Policies and Issues,

June 2019.

Ckearfield-FOA

Certification Training Clearfield is now

offering their customers an FOA

CERTIFICATION course. This course provides a

basic understanding of fiber optic technology, as well as

Clearfield product knowledge and how Clearfield’s integrated

product systems work together in a fiber network.

Substandard

Contractors - Fiber Optic Knowledge Doesn't Always Trickle

Down (EC Mag)

Another

Source Of Articles On Fiber

FOA

President and editor of this newsletter Jim Hayes has also been

writing a column in Electrical

Contractor Magazine for almost 20 years now. Electrical

contractors do lots of fiber work and this column has covered

some topics they are interested in including installation

processes, network design, fiber applications and a lengthy

series on dark fiber - what it is, how's its used and how it

benefits the growth of communication. A recent web site redesign

makes it easier to browse all these articles - just go to http://www.ecmag.com/contributing-authors/jim-hayes

and you can see all of them.

Upgrade

Your KSAs

You should

consider upgrading your KSAs - your knowledge, skills and

abilities related to your work in fiber optics and keep up to

date with new applications. It should help your business "bottom

line" - income and profit, that is.

FOA has just the place to learn - Fiber

U. Fiber U offers 15 free online courses

starting with an introduction to fiber optics for those new to

fiber and including courses covering installer skills topics

(basic fiber, basic skills, OSP construction and installation,

testing and OTDRs), a course for those designing fiber optic

networks, and six courses on specific applications of fiber

optics (FTTx, OLANs, fiber for wireless, cell tower antennas and

DAS, and data centers.)

If you are a working fiber tech, the applications courses can

enhance your ability to get business in those areas because you

will know the specifics of the applications. With so much work

being done on wireless (small cells, 4G/5G) and data centers

(small to hyperscale), understanding these applications can

certainly improve your prospects in those markets.

Learning more from the skills courses like testing and OTDRs is

a no-brainer, but you might look at our upgraded "Basic

Fiber Optic Skills Lab" too. You might find it will help

you upgrade your skills, but we have another aim for the basic

skills self-study.

If you are a contractor who has new employees that you want to

upgrade their skills or apprentices who are just starting in

fiber optics, the Basic

Fiber Optic Skills Lab lets them use their own tools

and components to learn installation skills they

use daily on the jobs. The new workbook we've added to the

basic skills lab guides the person taking the course

through the exercises and provides worksheets to record

the results of their labs. We've upgraded the virtual

hands-on (VHO) tutorials also and made them so you can

download and print them to help you with the steps in the

exercises.

Can

You Learn Hands-On Skills Online?

Knowledge is easy to learn online, but learning skills requires

"hands-on" practice and that requires tools and components to

practice with. Here at FOA, we've been working on an online

course that could help many techs learn new skills or improve

others using an online self-study course and their own

equipment. Recently,

we have updated the materials in the Fiber

Optics Basic

Skills Labs which includes cable preparation,

splicing, termination and testing. And we have created a Basic

Skills Labs - Copper Premises Cabling to cover UTP

(Cat 5) and coax copper cable processes. As with all Fiber

U courses, these are free.

The course on Fiber

U called "Basic

Fiber Optic Skills Lab" introduces you to the tools

and equipment then takes you through cable prep, splicing,

termination and testing. Recently we have been working on

improving the course to make it easier and more effective.

We've added a Basic Skills Workbook for each topic in

the course that you can download to guide you through the study

and hands-on exercises. We've updated what we call "Virtual

Hands-On" (VHO) tutorials where we use an analysis of the

activities to break them into step-by-step instructions that

help you learn the processes. We've also added new technologies

like splice-on connectors (SOCs) that have become very popular.

Similarly, we

have created a Basic

Skills Labs - Copper Premises Cabling to cover UTP

(Cat 5) and coax copper cable processes. It has a lab

workbook, VHOs on each topic and quizzes to allow you to

check your knowledge. If you have to tools, you can do

all the processes on your own.

If you are a newcomer to fiber optics, have completed the Basic

Fiber course and already have a set of fiber

tools, this course will help you to learn how to

use the tools and learn basic fiber installation practices

which you can practice using your own equipment. If you are a

CFOT or working tech now and want to learn some new processes,

this can help you too.

Like all Fiber U courses, the Fiber

U Basic Fiber Optic Skills Lab is free.

10GPON

Update In FOA Guide

FOA has

updated its page on FTTH PON protocols to include the latest

standards for 10GPONs. There are three standards, NG-PON2,

XG-PON and XGS-PON. As is common with all communications

networks, work on upgradeing network capability and speed starts

as soon as a network is introduced and PONs are no exception.

GPON has been the most widely used PON scheme for both FTTx

netowrks and passive optical LANs (OLANs) and GPON has been

upgraded to several versions with higher transmission speeds and

higher power budgets to allow greater distance, higher split

capability, or both. The assumption is that a fiber network has

a lifetime of up to 40 years, so upgrades to GPON have assumed

that they will use the same passive optical network architecture

and fiber type (G.652 singlemode.)

Furthermore, upgrades have been designed around coexistence with

current GPON networks. By utilizing different wavelengths, it is

possible to have these newer, faster networks sharing the same

passive optical network as the original GPON system, allowing

offering higher speeds to users while continuing to serve

current users without disruption. Some commercial users can take

advantage of higher speeds while typical consumers are well

served by GPON. One of the big advantages of the PON upgrade

standards is the ability to overlay networks. Thus a city could

operate one regular GPON network for consumer FTTH use and have

another, faster network operating on the same cable plant

independently, offering a higher level of service and security.

More on

PON Protocols in the FOA Guide.

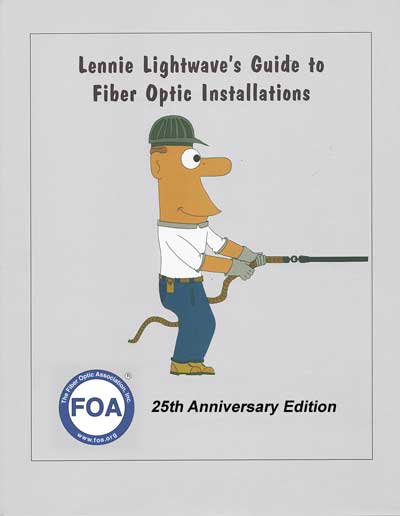

Introducing

Lennie Lightwave's Guide - 25th Anniversary Edition

FOA has

reprinted "Lennie

Lightwave's Guide" on its 25th anniversary in a special

print edition.

Many of you have used the current online version of Lennie's

Guide on the FOA website. Now you can have a slick printed

version - real paper - you can hold in your hand and read. Leave

a copy on your desktop to impress your friends, or on the table

in your company's reception area instead of out-of-date

magazines. Give them to your customers and employees to help

them learn fiber optics. Use it to prepare for FOA

certifications. FOA will be giving them away at conferences like

the IMSA Annual Conference in New Orleans later this summer.

You can get your own copies of Lennie

Lightwave's Guide at Amazon.com, only $9.95US.

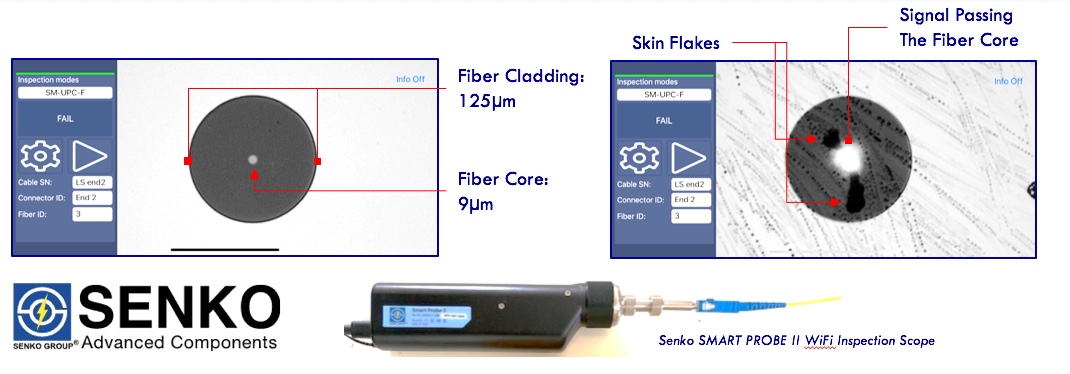

Another

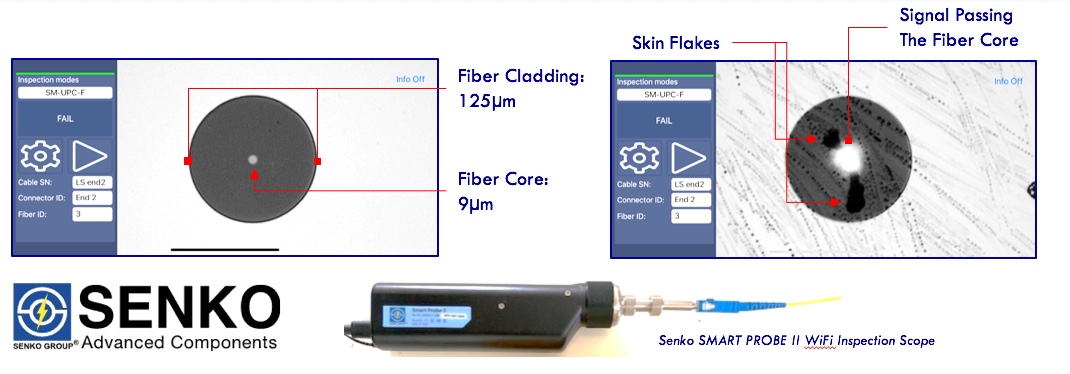

Look At Connector Contamination

Brian

Teague of Senko

Advanced Components sent us the results of an interesting

experiment he ran to show an unusual effect of the contamination

on a connector. He started with a clean SC/UPC singlemode

jumper, shown in the 400X image to the left. Then he connected

it to a 1310nm laser test source and measured the power out of

the fiber with a fiber optic power meter. Then he disconnected

the connector from the meter, touched the end to his finger,

contaminating the end of the ferrule as you can see in the image

on the right.

But then he connected the dirty connector to the meter and

measured the power again. The power was decreased by 0.22dB.

Yes, the contamination on the connector acted as an attenuator

to reduce the power considerably. Think what would happen if you

them mated it to another connector. Not only would you see the

attenuation caused by the contamination, you will probably see

even more loss caused by the gap created by the flakes of skin.

That's why you should inspect, clean and inspect again to ensure

all connectors are clean before testing or making connections.

Updates

We are

continually updating the Online Reference Guide to keep up with

changes in the industry and adding lots of new pages of

technical information. When you go to the FOA

Guide Table of Contents to see the latest updates - look

for  . .

PON

Protocols in the FOA Guide. 10GPON

Update In FOA Guide

Basic

Fiber Optic Jargon, OSP

Fiber

Optic Jargon and Fiber

Optic Jargon for managers.

FOA

has a new page on Restoration

The

updated Fiber

Characterization page in the FOA Guide goes in to more

depth on why fiber characterization is important, what tests

need performing and how to interpret results.

Practically every page in the section of the FOA Guide on Fiber

Optic Testing has been reviewed and updated, much of it based on

the new FOA textbook on testing. This includes pages on

measuring power, fiber attenuation, connector or splice loss and

cable plant loss. Browse

through the testing section and see what's new.

We've

started with a page in the FOA Guide on Fiber

Optic Network Management that describes what our advisors

think is important and created a page to introduce them to the

language and technology of fiber optics which we call "Fiber

Optic Jargon - Illustrated." Over time, we'll be expanding

this section and create a Fiber U self-study course also.

FOA has

created a new section of the FOA

Guide on OSP

Construction.

Inspecting

and Cleaning Connectors.

Dirty

connectors are one of the major problems in fiber optics,

causing high connector loss, high reflectance and contaminating

transceivers. Network operators claim that 15-50% of all network

problems can be traced to dirty connectors causing connection

problems.

FOA

Guide section on inspecting and cleaning connectors.

Go

to The

FOA Online Fiber Optic Reference Guide.

FOA

School Offers Toolkit With Online Training

Slayton

Solutions (FOA Approved School #156) is offering a simple

fiber optic tool kit that includes a 29-piece set of fiber

optic tools and a power meter along with training videos and

online instruction for only $499. 29 Piece Kit includes all

tools and devices a technician needs to install fiber optic

connectors and test optical power. Information

on the kit is available on YouTube.

You can contact them for more information at

slaytonsolutions@sbcglobal.net

or https://www.fiberopticsinstitute.com

New

FiberNext Job Board And Savings Club For CFOTs

FOA

Approved School FiberNext

has created an online job board for fiber techs and a special

"savings club" for CFOTs.

Job

Board

The

Job Board was designed to help connect employers with fiber

technicians and other fiber optic professionals. It is a place

where employers in the fiber optic market can post job

openings and a place where fiber optic professionals can post

that they are looking for employment. Please feel free to post

an opening or browse for your next job or employee. https://fibernext.com/job_board.php

Savings Club

FiberNext, besides being an FOA approved school is also a

distributor. FiberNext invites FOA CFOT®s to join the “FiberNext

CFOT® Club to get special savings on selected fiber optic

products. Visit https://fibernext.com/cfot_club.php to

sign up today ”

Recycling

Fiber Optic Cable

We

received this note from Steve Maginnis, LD4Recycle/ CommuniCom

Recycling on recycling fiber optic cable:

We have 3 Processors gearing up to accept fiber optic

cable (FOC). As we all know, all FOC is not the same. Several

truckloads of “typical” FOC scrap from FOC mfgrs and “typical”

FOC and Coax cable have been studied and tested.

Therefore, today you can begin contacting me with the type FOC

material or scrap you toss to the landfills today. We need to

quantify the expected feedstock. Our expectation for quantities

is quite large (tons) but there is a capacity limit. And I do

have several processors that can take ALL materials and others

that can accept LIMITED types of FOC material and quantity.

Contact:

Steve Maginnis

LD4Recycle/ CommuniCom Recycling

(Visit our new

website)

sm@LD4Recycle.com

803.371.5436

Safety

On The Job

Safety is

the most important part of any job. Installers need to

understand the safety issues to be safe. An excellent guide to

analyzing job hazards is from OSHA, the US Occupational Safety

and Health Administration. Here

is a link to their guide for job hazard analysis.

FOA also has lots of information on safety: FOA

Guide, YouTube

video and a Safety

Poster

Best

Practices Guide For Underground Construction

We assume

you are familiar with the "One Call" and "Call Before

You Dig" (811) program, but are you also familiar "Click

Before You Dig.com" and with the people behind it -

the Common Ground Alliance and their Best Practices website?

CGA

is a member-driven association of 1,700 individuals,

organizations and sponsors in every facet of the underground

utility industry. Established in 2000, CGA is committed to

saving lives and preventing damage to underground

infrastructure by promoting effective damage prevention

practices. CGA has established itself as the leading

organization in an effort to reduce damages to underground

facilities in North America through shared responsibility

among all stakeholders.

Officially

formed in 2000, the CGA represents a continuation of the

damage prevention efforts embodied by the Common

Ground Study.

Sponsored by the U.S. Department of Transportation and

completed in 1999, this Study represents the collaborative

work of 160 industry professionals who identified best

practices relating to damage prevention. Any

best practice or program endorsed by the CGA comes with

consensus support from experts representing the following

stakeholder groups: Excavators, Locators, Road Builders,

Electric, Telecommunications, Oil, Gas Distribution, Gas

Transmission, Railroad, One Call, Public Works, Equipment

Manufacturing, State Regulators, Insurance, Emergency

Services and Engineering/Design.

Read

the CGA Best Practices Guide here.

Here

are all the CGA resources for damage prevention.

The word on

the "Dig Once" program is getting out - FOA is getting calls

from cities asking us for information and advice. It helps that

the current Administration is trying to convince cities of the

advantages of installing ducts or conduits when they dig up a

street so they don't have to do it again. Here are some links

for more information.

The DoT page on the administration’s Executive Order: http://www.fhwa.dot.gov/policy/otps/exeorder.cfm

From the Council of State governments: http://www.csg.org/pubs/capitolideas/enews/cs41_1.aspx

From the city of San Francisco: http://sfgov.org/dt/dig-once

An article about Dakota County, MN: https://muninetworks.org/tags/tags/dig-once

And

the one to download and hand out:

A “How To” Guide from The Global Connect Initiative: https://share.america.gov/wp-content/uploads/2016/04/6.-GCI-Dig-Once.pdf

Useful

Online Resources

We often

have contacts give us online links for useful information which

we like to share with our readers. Here are two:

Why

We Warn You To Be Careful About Fiber Shards

Photo courtesy Brian Brandstetter, Mississauga

Training Consultan

FOA

Facts

FOA is a

non-profit professional association chartered to promote

professionalism in fiber optics through education, certification

and standards. FOA is mostly known for certifying techs -

mostly CFOT®s

-Certified Fiber Optic Technicians - but also may be CPCTs -

Certified Premises Cabling Technicians or corporate

members involved in fiber optics.

FOA is a "virtual organization" - we have no "brick and mortar"

presence. We operate over the Internet with operations centered

in California, with active workers and volunteers in locations

as diverse as Texas, Ohio, Canada, Singapore, Malaysia, Denmark,

South Africa, the Middle East and many more.

Being a virtual organization, FOA has very low overhead,

allowing us to offer cost-effective certifications and many free

programs to support our industry.

As of today, FOA has certified this many techs. About 90% come

from our schools but many experienced techs have become FOA

CFOT-certified directly through our "Work-to-Cert"

program.

FOA has almost 200 approved training organizations in about 40

countries around the world around the world.

FOA

Certifications Now Last For 3-Years

Beginning

in 2019, all FOA certifications issued or renewed will be for a

period of 3 years. Most certification bodies worldwide have

standardized on 3 year certifications. FOA has been working with

a number of organizations that use our programs but have

standardized on 3 year certifications. FOA has decided that it

is time to change our policies to align with the majority of

other organizations.

Remember that FOA certification renewals include all the

certifications one individual has for one price. FOA does not

charge for any additional certifications, so, for example, if a

CFOT also has specialist certifications like the CFOS/T or

CFOS/S, they are included at no additional cost when the basic

certification is renewed.

FOA has 14

fiber optic certification programs covering every aspect

of fiber optic network design, installation and operation.

Primary

Certifications: CFOT (basic fiber), CPCT (premises cabling),

CFOS/O (outside plant, taught with CFOT included) and CFOS/D

(fiber optic network design).

Skills Certifications (for installers and techs, requires

CFOT): CFOS/S (splicing), CFOS/C (connectors/termination),

CFOS/T (testing), CFOS/FC (fiber characterization).

Applications Certifications (for techs or anyone, including

managers and supervisors): FTTH (fiber to the home), CFOS/L

(optical LANs), CFOS/DC (data centers), CFOS/A (fiber to the

antenna), CFOS/DAS (distributed antenna systems) and CFOS/W

(fiber for wireless)

(what you are reading)

(what you are reading)

FOA monitors the trade press, websites and other

resources continually to look at what's happening in many

technologies that affect fiber optics. We're tracing

technologies as diverse as wireless, IoT, autonomous vehicles,

smart cities, energy, or anywhere fiber is used to bring news to

our readers.

FOA continually updates our technical materials, online and

printed, and our curriculum to ensure our readers have access to

the latest technical information and our schools teach the

latest technology and applications. Our printed books are being

updated right now.

FOA created the

FOA Online Guide as a non-commercial trustworthy technical

reference almost a decade ago so the industry would have a

reliable technical reference. In the last year, over 1million

visitors downloaded about 4 million pages of technical

information.

FOA offers free online self-study programs at Fiber

U. In 2017, the number of online sessions doubled to

200,000. Many of those are preparing for FOA certification

programs - taking courses at our schools or using the "Work-to-Cert"

program. Some of our schools are requiring Fiber U programs as

prerequisites for their classroom courses so they can spend more

time on hands-on activities.

FOA offers over 100 educational YouTube

videos that have been viewed 2.4 million times.

FOA offers its training programs to other organizations at no

cost to help them train their members properly in fiber optics.

For example, FOA has been working with the Electrical Training

Alliance (IBEW/NECA) for over 20 years, training their

instructors for their apprenticeship programs. We work with many

other organizations and companies to provide the materials they

need.

FOA has about 300 corporate

members - companies in various aspects of the fiber optic

industry worldwide that we list online and offer discounts on

certifications and renewals.

FOA provides speakers for many conferences and even

presentations for use by other organizations to educate people

on the aspects of fiber optic communications.

FOA has a program to provide classroom

materials for STEM

teachers (science, technology, engineering and math)

introducing K-12 students to fiber optics and creating science

projects.

FOA provides forums for discussion on various social media. Our

LinkedIn groups have about 5,000 members each. If you are not

joining us on social media yet, please do.

Interested

In A Career In Fiber Optics?

FOA has created a new YouTube video to introduce students to

careers in fiber optics. It was made for showing to high school

and junior high students interested in tech careers but anyone

interested in a possible career in this field will find it

interesting. If you have kids in school or know teachers, let

them know about this too. Watch the FOA

Careers In Fiber Optics Video on YouTube and visit the FOA

Careers In Fiber Optics web page at www.foa.org/careers/.

ts

1-844-440-0047

www.fiberoptictraining.com

Fiber

Optic Education For Students At Any Age

We hear

about fiber optics all the time - it's in the news whenever we

hear articles about high tech, the Internet and communications,

and many communities are getting "fiber to the home." But few

people really understand fiber optics or how it works. FOA is

focused on educating the workforce that installs and operates

these fiber optic networks but we're always getting inquiries

from STEM (science, technology, engineering and math) teachers

who want to introduce fiber optics to younger students in K-12

grades or technical schools.

We

start with the FOA

Careers In Fiber Optics Video on YouTube and visit the FOA

Careers In Fiber Optics web page at www.foa.org/careers/.

These are for students who think they might be interested in

careers in fiber optics and want to know more about what fiber

techs do.

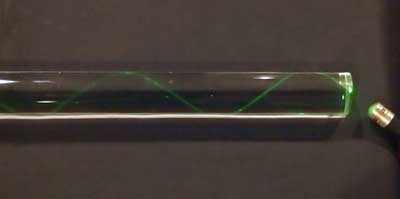

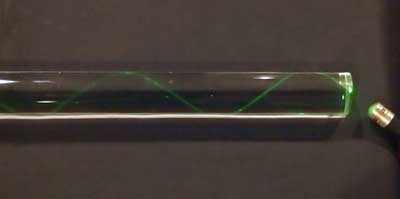

Using red laser light (a VFL here but a laser pointer works

also) to show how fiber guides light.

FOA has begun developing a series of YouTube videos intended for

teaching students in elementary, middle and high schools about

fiber optics. The first FOA video is titled "Fiber

Optics For Teachers." With this video, we show teachers

how fiber works and carries signals and then explains simple

experiments to demonstrate how fiber optics works in the

classroom using some plastic fiber and a laser pointer. Since

many teachers do not know where to get the fiber, the FOA offers

to send them a sample for use in demonstrations in their

classroom (USA only right now.)

At the end of the video, teachers are given directions on how to

request samples of the plastic fiber from the FOA.

This video joins the "Fiber Optics Live" series How

Light Travels In A Fiber, Fiber

Attenuation and Connector

Loss that show how fiber works using simple experiments

that can be duplicated in any classroom. More videos will be

coming soon.

If you have kids or know some teachers who would be interested,

please send them to the introductory video Fiber

Optics For Teachers and we'll be glad to help them

get started with some entertaining programs for their

classrooms.

Resources

For Teachers In K-12 And Technical Schools

Teachers in all grades can introduce their students to fiber

optic technology with some simple demonstrations. FOA has

created a page for STEM or STEAM (science, technology,

engineering, arts

and math) teachers with materials appropriate to their

classes. Fiber Optic

Resources For Teachers.

If

you have kids in school or know teachers who are interested,

send them to the FOA page Fiber

Optic Resources For Teachers.

Should

Your Company Become An FOA Corporate Member?

As all FOA

individual

members know, they join the FOA by becoming certified,

mostly taking their CFOTs but some CPCTs, either by

attending a FOA approved school or joining directly based on

field experience (our "work to cert" program.) Over the years,

we've been contacted by manufacturers, contractors, consultants,

and other types of organizations who ask about becoming members.

We don't certify companies or organizations, we told them, so we

were not sure what we could offer as a benefit of membership.

But then, companies asked about using our educational programs

to train employees, how they could get listed on the FOA website

as service providers or if they could get a quantity discount on

membership or certification for all the FOA members working for

them. That began to sound like a benefit for being an FOA

corporate member. And providing a list of useful suppliers to

the market could be a benefit to the industry as a whole.

So FOA has quietly been letting companies and other

organizations join the FOA to take advantage of those benefits

so we now have several hundred corporate members. We've put then

into a database and listed them on the FOA website in map

and list

form. Here's the map.

The online map

and list

can be used to find suppliers and service providers.

The map, like our map of schools, lets you find the FOA

corporate members close to you. The table form lists them

by category: Installer/Contractor, Component Manufacturer,

Installation Equip. Manufacturer, Transmission Equipment,

Services/Consulting, Distribution and Users of Fiber Optic

Networks. You can sort the tables to find members meeting your

needs, e.g. by location, certifications offered, etc. Click on

any column heading to sort that column; click twice to sort in

reverse order.

How

Does An Organization Become An FOA Corporate Member?

Simple,

just fill in the online

application form. When your application is accepted, you

will be asked to pay the one time membership fee - $100US. You

will then be listed on the online

map

and list,

have access to exclusive FOA educational materials for your

employees and get discounts on certifications and

renewals.

Events of

Interest: FOA

now posts events on our LinkedIn groups, Facebook page and

other social media

FOA

has a company page and three LinkedIn Groups

FOA

- official company page on LinkedIn

FOA

- covers FOA, technology and jobs in the fiber optic marketplace

FOA

Fiber Optic Training - open to all, covers fiber optic

technology and training topics

Grupo

de La Asociación de Fibra Óptica FOA (Español)

RETURN

TO INDEX

FOA Resources

FOA Resources

FOA

Standards:

FOA offers free standards for datalinks and testing the

installed fiber optic cable plant, patchcords and cable, optical

power from transmitters or at receivers and OTDR testing. Look

for the "1

PageStandard" web page and in the FOA Online Reference

Guide.

NECA/FOA

301 Fiber Optic Installation Standard

Standards

cover components and systems and how to test them, but rarely

get into installation issues. The FOA NECA 301 standard which

covers installation of optical fiber systems has been revised

for the second time, adding considerable new materials. This

standard is derived from FOA educational material put in

standards form and approved by ANSI as an American National

Standard. It's specifically written to be used in contracts to

define "installation in a neat and workmanlike manner." The

standard is available from NECA.

FOA members can go

here for instructions on how to download your free copy.

RETURN

TO INDEX

Free

Fiber U Self-Study Programs

FOA's

"Fiber U" free online self-study programs help you learn about

fiber optics, study for FOA certifications or use them to help

create "blended learning" classes. There are two new free online

self-study programs on Fiber

U. Fiber Optic Network Design is for those interested in

learning more about how to design fiber optic networks or

studying for the CFOS/D certification. FTTx is for those wanting

to know more about fiber to the "x" - curb, home, wireless, etc.

- or studying for the CFOS/H certification.

Got to Fiber U

for more information.

Fiber U

Online Self-Study Programs Offer Certificates of Completion

FOA has

been offering quite a few free online self-study programs on Fiber

U, our online learning site. We are always getting

questions about getting a certificate for completing the course

online, so we have setup an option to take a test online and get

a certificate of completion for these online courses.

While it's not FOA certification, FOA will recognize a Fiber

U Certificate of Completion as background experience to

qualify for applying for FOA certifications. We also intend to

expand the program to more specialized topics as preparation

for FOA specialist certifications.

If you have associates that want to get started in fiber,

have them take this course online to get started. Go to Fiber

U and get started.

FOA

Books And Publications

Updated

Books

Many textbooks are behind the technology because they are

rarely updated. FOA really keeps our textbooks up to date. We

did a major update a year ago and another was just completed.

The The FOA

Reference Guide To Fiber Optics has been updated

to reflect new components like OM5 fiber, testing for fiber

characterization and more information on installation.

The FOA

Reference Guide To Outside Plant FIber Optics

has been expanded to include an extensive section on outside

plant construction taken from Joe Botha's

OSP Construction Guide textbook. This additional

material is being added to support the new FOA CFOS/O OSP

tech certification program which now includes of OSP

construction.

FOA

Basic Fiber Optic Textbook Available in French and Spanish

Libro

de Diseño para Redes de Fibra Óptica en

Español - FOA

Design Book Available In Spanish Online

FOA has translated the FOA Guide To Fiber

Optic Network Design book and made it available online to

those studying for the CFOS/D Certification but whose native

language is Spanish. You

can access the Spanish translation of the Design book here.

A printed version will be available in the near future.

Lennie

& Uncle Ted Guides - Perfect For Getting Started

Lennie

and Uncle

Ted's Guides have moved to the FOA website.

Lennie is the place where many if not most fiber techs

begin their education. FOA has just updated the two

guides to ensure they stay relevant - more than 20 years

after they were first written.

Lennie goes all the way back to 1993 when he was created

as the mascot of the original "Fiber U" conference - the

same Fiber U that is now the FOA's web-based training

site. Lennie

Lightwave's Guide To Fiber Optics was created

as a beginner's introduction to fiber optics. Over

60,000 printed version of Lennie's Guide were given away

and it became one of the first commercial web pages in

1994. Uncle Ted's

Guide To Communications Cabling was written a

few years later to introduce techs to "Cat 5" - UTP

wiring - that had only recently been standardized in

TIA-568.

Lennie and Ted's Guides are used in the current Fiber U

online self-study programs and are still the best place

to start learning about fiber optics.

Lennie

and Uncle

Ted's Guides are online at the links here, can be

downloaded as printable PDFs and are now also available

as free iBooks on iTunes.

Lennie

Lightwave's Guide to Fiber Optics and

Uncle

Ted's Guide To Communications Cabling

are now available free to iPad users who can download them from

the Apple iTunes store. Of course they are still available

online or for download.

You can also find these free guides on the FOA website - go here

for all the links: Lennie

Lightwave's Guide to Fiber Optics and Uncle

Ted's Guide To Communications Cabling

Download PDFs of Lennie

or Uncle Ted.

RETURN

TO INDEX

FOA

iPad Apps

FOA

LossCalc

FOA

LossCalc estimates the optical loss of a fiber optic link. This

will save time for the installer of a fiber optic link needing

to know whether test results are reasonable and/or make a

"pass/fail" determination. It can also help the designer of a

link to determine if communications equipment will operate over

this link. FOA

LossCalc estimates the optical loss of a fiber optic link. This

will save time for the installer of a fiber optic link needing

to know whether test results are reasonable and/or make a

"pass/fail" determination. It can also help the designer of a

link to determine if communications equipment will operate over

this link.

By choosing the type of link (singlemode or multimode) and

specifying the length of the fiber and numbers of connections

and splices, it will calculate the end to end loss of the link.

The app has default specifications for singlemode and multimode

links or the user may create custom setups with specifications

appropriate for any application. http://itunes.apple.com/us/app/foa-losscalc/id476262894?mt=8&ls=1

RETURN

TO INDEX

The

FOA has many videos on  ,

including two Lecture Series (Fiber Optics and Premises

Cabling), Hands-On lectures on both and some other informational

and instructional videos. For all the videos, go

to the FOA Channel "thefoainc" or use the direct links

below. ,

including two Lecture Series (Fiber Optics and Premises

Cabling), Hands-On lectures on both and some other informational

and instructional videos. For all the videos, go

to the FOA Channel "thefoainc" or use the direct links

below.

View

a complete list of FOA Videos with links to each video on

YouTube.

Where Are

The Jobs In Fiber Optics? FOA talks about all the

applications for fiber optics, what jobs involve and the

qualifications for the workers in the field.

Fiber

Optics - Live! A

series of videos that use lab demonstrations to show how

optical fiber works.

Cabling

Project Management - what's involved in a

copper/fiber/wireless project -advice for the customer and the

contractor

Hazards

Of Counterfeit Cable

You may

have read the stories we have written about the counterfeit

"Cat 5" cable made from copper-clad aluminum rather than pure

copper. Recently we tried an unscientific burn test on the

cable compared to a known good UL tested cable and posted a

video on YouTube. You can see the results below.

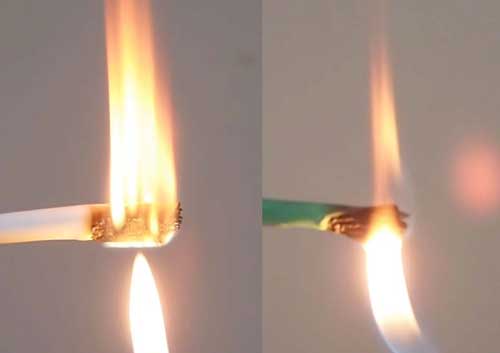

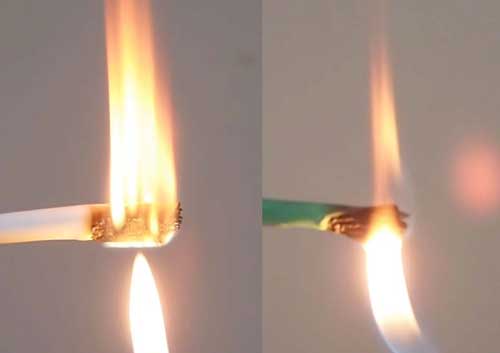

Counterfeit

Cable Real UL-rated cable

The

difference is obvious and the danger is real. Watch the video

on YouTube: Premises

Cabling Lecture 11: Counterfeit Cat 5 Cabling

View a

complete list of FOA Videos with links to each video on

YouTube.

View

all the FOA Channel on YouTube.

RETURN

TO INDEX

FOA

Schools

New

School:

Midwest

Communications Technologies, FOA

Approved School #378.

Find

a listing of all the FOA-Approved schools here.

Find An FOA-Approved Training

Organization

Most

inquiries we get regarding finding a FOA-Approved training

organization want to know two things: what school is closest to

me or what school offers the certifications I need. The FOA has

about 200 training organizations we have approved worldwide so

finding the right one can be difficult! We've been looking at

ways to make it easier, and we think we've got a good solution.

In fact we have two solutions.

First we have added a sortable

table of all the FOA-Approved schools.

You can also use our FOA

Google Map to find FOA-Approved schools.

What

Should A Fiber Optics or Cabling Tech Know and What Skills Do

They Need?

FOA

certifications are based on our KSAs - the Knowledge, Skills and

Abilities that techs need to succeed. Read the FOA KSAs

for fiber and cabling techs.

School News

Feedback

We always

enjoy feedback, especially when it shows how great some FOA

instructors are. These came from students of Tom Rauch, an

instructor at BDI

Datalynk:

"I took your fiber optics certification courses this past March.

I just wanted to let you know that in two weeks I start working

as a fiber optic technician with ___ up in ___. You mentioned on

the first day of the course that there is always one guy in

class who had rubbed his last two nickels together to be there

and, in that instance, I was that guy. Now I'm going to be able

to provide for my family like never before and I owe it to the

certification that I received from you and BDI Datalynk. I just

wanted to thank you again."

"Thanks to our tremendously knowledgeable and patient instructor

Thomas Rauch, who was not only generous in sharing his wealth of

information, but he did so with ease, humor and in a way that

invited curiosity and participation. He was encouraging and

proud of our accomplishments and helped us learn from our

mistakes in a way that did not break our confidence, rather it

pushed us to better results the next go around. The hands on

labs were just AWESOME!" Just thought you should know what a

class act you have representing you in his travels..... but then

again you probably already knew that! : )

In almost 19 years at Verizon and having held numerous

positions, I have gone through many training sessions. I cannot

remember ever having been actually looking forward to coming

back to class quickly after lunch, to get back to the hands on

activities, and walking away with the sense of empowerment that

the information presented was not only relevant but dead on

point accurate! I will be signing up for the Outside Plant class

on March! I can't say enough good things about Tom and his

impact! Feel free to quote me, I can only imagine that he will

open so many doors and change so many lives in the years to

come, with his style of teaching! Great experience, awesome job!"

IBEW

and FOA Partner on Fiber Optic Training

The

International Brotherhood of Electrical Workers (IBEW) and the

National Electrical Contractors Association(NECA) through the

National Joint Apprenticeship and Training Committee

(NJATC) in

a partnership with the FOA has published a new textbook for

training IBEW apprentices and journeymen in fiber optics. The

new textbook uses the material from the FOA Reference Guide To

Fiber Optics with new material and photos from other NJATC

training partners.

Quote

from one of our certified instructors: I want to thank

you and your organization for all the resources you provide for

the students and the opportunity to offer the certification to

the students. The fact that you published the book yourself to

get the cost down and the unlimited free resources on your

website shows a commitment to the public that is second to none.

I let it be known to the students that the FOA is the best in

the industry at supplying knowledge and resources related to the

communication industry. I look forward to passing on the

information that you provide for the industry.

RETURN

TO INDEX

Good

Question! Tech Questions/Comments Worth Repeating

New:

The FOA Fiber FAQs

Page (FAQ s = frequently asked questions) gathers up

questions readers have asked us and adds tech topics of

general interest.

Questions

From FOA Newsletter Readers

April 2020

Restoration

Time

Q: Do you have any statistical data on how long (on