Patchcords in Fiber Optic Networks

Patchcords are used to cross-connect

installed cables and

connect communications equipment to the cable plant.

The choice of

patchcords is very important to the performance of the

network. Choose

patchcords with these criteria:

- Fiber

type must match the type of fiber in the cable

plant. For multimode cable, use only 50/125

patchcords with 50/125

fibers in cables and 62.5/125 patchcords with 62.5/125

fibers

in cables. Although there are several types of

each size fibers,

matching the fiber type exactly is generally not

required, e.g you can

use OM3 patchcords on OM2 or OM4 cable plants.

Singlemode fiber is

mostly the same, but some long distance fibers

have different mode

field diameters and should use patchcords with

matching fibers. Some

patchcords are made from special bend-insensitive

fibers.

Although there has been some controversy about the

compatibility of BI

fibers to normal fibers, manufacturers seemed to

have adapted their

designs to ensure compatibility.

- Choose

patchcords with proper cable

jacket color codes. This can help prevent

mismatching fibers, especially multimode

fibers.

- Choose

patchcords with the correct

matching connectors.

Choose connector types that match the connectors

on patch panels and

equipment. Since many cable plants use one type of

connector and the

equipment another, e.g. STs on a multimode

cable plant and LCs on the equipment, you may need

to stock hybrid

patch cables with different connectors on each end

to make the

connection. For singlemode networks, the

connectors must also have the

proper finished ferrule ends, either PC or ultra

PC polish for most

systems or angled PC (APC) connections for higher

speed systems or

those carrying AM video. Do not mix PC and APC

connectors as that may

damage them! The TIA 568

color code for connector bodies and/or boots is

Beige for multimode fiber except aqua for

laser-optimized fiber, Blue

for singlemode fiber, and Green for APC (angled

PC) connectors.

The performance of a fiber optic network

(and copper

networks too) can be undermined the performance of the

patchcords used

for interconnects and connecting communications

equipment. But it's

easy to take patchcords for granted. They are

inexpensive, often not

tested properly if at all, and sometimes treated

badly.

Most

users

buy patchcords in bulk and store them in boxes until

they are

needed, when they are unpackaged and plugged in. Some

users hang them

on the sides of the equipment racks. That's not how

they should be

handled.

When

it

comes to patchcords, there are three issues: quality,

cleanliness

and condition. You might assume that the patchcords

you buy are good

quality. They come in plastic bags usually with a

label that identifies

the fiber and connector type, length and test results.

We’ve seen cheap

imported patchcords with connectors with locking

mechanisms that would

not connect because they were improperly made and

connectors with

losses that tested at 1 dB although the label said 0.2

dB. Under closer

examination, the label appeared to be from a copy

machine not a

printer, so I doubt the cable was even tested. While

it's inconvenient

and expensive, testing every patchcord is highly

recommended per

the standard test, FOTP-171. If you do not test

them and have network problems, then look at them

first when troubleshooting the system.

Testing Patchcords

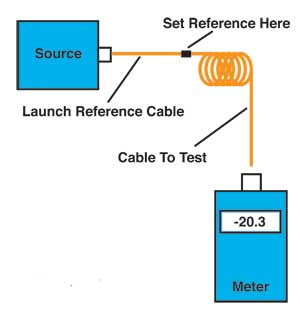

For

testing the loss of a

patchcord, you only need an 850 nm LED light source

for

multimode cable or 1310 laser for singlemode, a fiber

optic power meter

and some reference patchcords. Just remember that the

patchcords used

for references in testing must be good for tests to be

valid, so you

test them as you would other patchcords, just more

often.

Testing

patchcords

is similar to testing any fiber optic cable. Use one

reference patchcord to set a 0 dB reference. Connect a

patchcord to

test to the reference patchcord with a mating adapter.

Connect the

power meter to the other end of the patchcord and

measure the loss.

Since the length of the fiber is short, the loss

contribution of the

fiber is ignorable. And since one end of the cable is

attached to the

power meter, not another cable, you only measure the

loss of the one

connection between the reference cable and the cable

under test, so you

can test each connector individually.

To

complete

the testing of the patchcord, reverse the cable you

are

testing to check the connector on the other end.

Sometimes you will

find one bad connector and can replace it to make the

patchcord useful

again. But often the cost of replacing the connector

may be higher than

replacing the patchcord itself.

If

your

test equipment has different connectors than the

patchcords you

are testing, you will need hybrid reference cables

with connectors

compatible with the equipment on one end and the

patchcord connectors

on the other end. You will also need the correct

connector adapters for

your power meter.

Obviously,

all

reference cables used for testing must have high

quality connectors

to get reliable test results. Use this same method to

test your

reference cables against each other and discard any

with high losses,

usually those with losses over 0.5 dB.

Cleaning Patchcords

Cleanliness

is

an issue with brand new cables as well as used ones.

All connectors

should always have the polished ferrule covered by a

“dust cap” to

protect the end of the connector ferrule from damage

and dirt. However,

a user recently told me that after examining many

connectors with a

microscope, he understood why they were called dust

caps, they were all

full of dust. The dust cap should be used to protect

the connector

ferrule, but do not assume it keeps it clean. You must

clean connectors

before inserting them in mating adapters or active

devices to ensure

they are really clean. Here

are directions for cleaning.

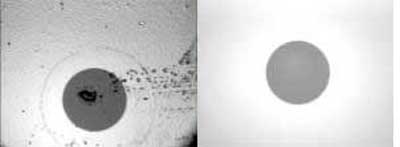

Cleaning Removes Dirt That Causes Loss

Those

cables

connecting equipment to the cable plant or hanging on

the sides

of racks are often mistreated, leaving kinks in the

cable or scratches

and scuffing on the connector ferrules. With the

reference cables used

for testing, the continual mating to other connectors,

even when

carefully cleaned before use, will cause scuffing that

increases loss

over time.

What this means is patchcords need continuous

inspection

and testing. It only takes a minute but can save you

lots of

troubleshooting time. Start

by checking the connector ferrules with a fiber

optic inspection microscope, preferably around

100 power, then test according to the procedure

above.

Handling Patchcords

Patchcords are often subject to poor

treatment. They are

often hung off communications equipment or patch

panels stressing the

fiber at the back of the connector. When they are too

long, they are

bundled and hung in large piles on the side of

equipment racks. Kinking

is always a problem. Ideally, patchcords should be the

right length,

supported below the connection and carefully placed to

prevent stress.

Unfortunately, that is often not the case and network

performance may

suffer. Don't let your patchcords look like this:

|