Connector Types and Terminology – What's In A Name?

Rarely do FOA instructors present a fiber optic

seminar without getting some questions on what some

connector terminology means or how such a term or

connector name originated. Since some of us have been

in the business for over 25 years ourselves, we do

remember some of the origins of these terms and find

it amusing to share the stories. But we’ll also cover

some important information about fiber optic connector

design and termination along the way.

The AT&T Biconic

The AT&T Biconic

Some of you may remember the Biconic and SMA

connectors which were the most popular connectors 25+

years ago. (Here

is the FOA Tech Topic that identifies most popular

connectors from the history of fiber optics.)

AT&T named their first commercial fiber optic

connector the “Biconic” since the connector had a

conical molded-plastic ferrule that fitted into a

“bi-conical” mating adapter when connected to another

connector. The original Biconic was actually molded

around the fibers to get exact centering, a practice

that stopped when they developed a way to insert a 125

micron ( 5 mil) pin in the plastic molding cavity to

produce a connector ferrule with a hole into which

fibers could be epoxied.

SMA

SMA

The SMA connector was the first connector widely used

for data links using multimode fiber. It was developed

by Amphenol using the hardware from the “SubMiniature

A” microwave connector, hence it’s name, with a

precise 1/8 inch machined metal ferrule.

The next major development in fiber optic connectors

came from Japan, with the development of the ceramic

ferrule. Metal ferrules had a problem with glass

fiber. The uneven expansion coefficients sometimes

caused the adhesive to fail, allowing the fiber to

extend or retract, a process called “pistoning.” The

ceramic ferrule had a very low expansion, like glass,

so the adhesive held better, the connector could be

polished to a finer finish and performed better over

extremes in temperature.

NTT FC

NTT FC  AT&T ST

AT&T ST  NTT SC

NTT SC

The “FC” or “fiber connector” from NTT (Nippon

Telephone and Telegraph) was the first connector to

use the 2.5 mm ceramic ferrule. Shortly thereafter,

AT&T introduced the “ST” or “straight terminus”

(contrasting to the “biconical” – get it?) that used

exactly the same ceramic ferrule as the FC but

replaced the screw-on nut of the FC with a bayonet

lock like a BNC coax connector, simplifying and

speeding up connector insertion. NTT responded a

couple of years later with the “SC” or “subscriber

connector” and the ST and SC dominated fiber optics

for over a decade.

The 2.5 mm ferrule was also used in the FDDI and ESCON

connectors, both named for the systems for which they

were designed. The connectors with two ferrules, one

for fibers transmitting and receiveing in opposite

directions, are called "duplex" connectors.

FDDI

FDDI  IBM ESCON

IBM ESCON

The next confusing nomenclature for fiber optic

connectors came from the polishing of the end of the

ferrule, giving us “PC,” “Ultra PC” or “Super PC” and

“APC” connectors. As the long-haul industry moved from

multimode (MM) to singlemode (SM) fiber around 20

years ago, the reflections at SM connections caused

big problems with most laser sources. The reflections

actually interacted with the lasers, causing

instability and noise in the laser itself.

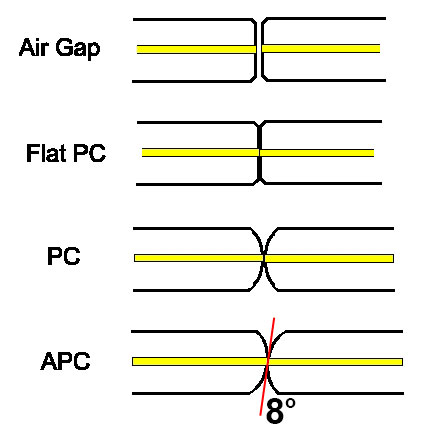

Early connectors like the biconic and SMA, which

did not have keyed ferrules and could rotate in mating

adapters, always had an air gap between the connectors

to prevent them rotating and grinding scratches

into the ends of the fibers. The air gap between

the fibers causes a reflection when the light

encounters the change in refractive index from the

glass fiber to air in the gap.

Beginning with the ST and FC, which had

keyed ferrules, connectors were designed to contact

mating ferrules tightly, creating what we now

call “PC” or “physical contact” connectors.

Reducing the air gap reduced both loss and back

reflection, since light has a loss of

about 5% (~0.25 dB) at each air gap. While air gap

connectors usually had losses of 0.5 dB or

more and return loss of 20 dB (1%), PC connectors had

typical losses of 0.3 dB and a return loss

of 30 to 50 dB (0.1 to 0.001%.)

Connectors use a number of polishing techniques

to create a convex end to the connector ferrule to

insure physical contact of the fiber ends. Hand

polishing is done on a rubber pad and machine

polishing uses concave polishing fixtures. “Super PC”

or “Ultra PC” are simply marketing names various

manufacturers give to their polishing processes.

The final solution for singlemode systems extremely

sensitive to reflections, like CATV or high bitrate

telco links, was to angle the end of the ferrule 8

degrees to create what we call an “APC” or

“angled PC” connector. Then any reflected light

is at an angle that is absorbed in the cladding of the

fiber.

It seems like more recent connectors, like the “SFF”

or “small form factor” connectors were named by the

marketing department instead of engineering, which is

why we have names like “Volition” and “OptiJack.”

AT&T LC

AT&T LC

But the

exception is the "LC" or lightwave connector.

A new class of connector introduced in the late 1990s

was the “MT” (“mass termination” or

"multiple termination") connector. The first was a duplex

connector, the “MT-RJ” where “RJ” refers to the

“RJ-45” style of copper connector whose form factor it

emulates. These multi-fiber connectors also come with

one or more rows of 12 or 16 fibers, called "array

connectors" or MPO

- "multi-position optical," "multi-fiber push-on" or a

trade name

"MTP."

MPO

MPO  MT-RJ

MT-RJ

Fiber

Optic Connector Identifier - What Connector is

THAT?

|