Reference Test Jumper

Cables and Mating Adapters

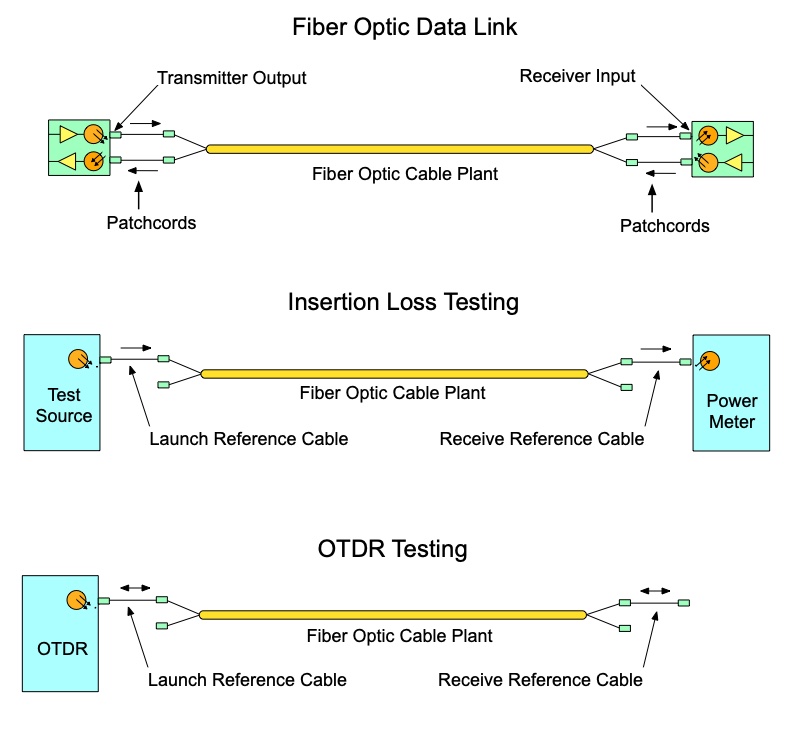

- In order to test

cables with a power meter and source or with an OTDR, one

needs to

establish test conditions. The test

conditions are similar to how the actual cable plant will be used

when communications equipment is connected (see below.) For

insertion loss

testing, this requires reference launch

jumper

cables to connect the test source to the

fiber in the cable under

test and receive cables to connect the fiber

optic

power meter. For OTDR testing, this requires

a reference launch cable to connect the OTDR to the fiber in the cable

under test and a receive cable at the far end of the fiber.

Reference cables used with test equipment

function similarly to the patchcords used connect the communications

equipment to the cable plant. A fiber optic test source is similar to

the transmitter of a datalink and an optical power meter is similar to a

receiver, so the test made with the source and meter, called an

insertion loss test, tests a fiber in the cable plant in a manner

similar to how it is used when operating as a data link. Thus the

reference cables can be considered substitutes for the patchcords. The

launch cable can be used to set the test conditions, including modal

conditions in multimode cable, and the reference connector on the launch

cable mated to the connector on the fiber under test is used to test

the quality of that connection. At the far end, the receive reference

cable connector tests the connector on the cable under test and connects

to the meter to measure the loss.

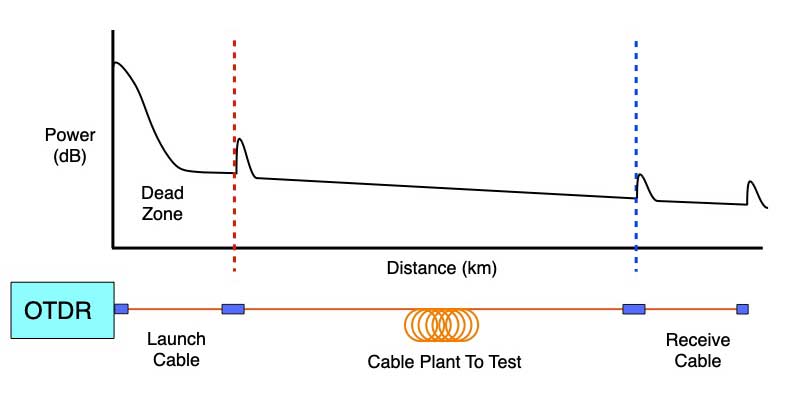

An OTDR tests the fiber differently, using the backscatter from the

fiber to create a snapshot of the fiber. See below. (For more information on OTDR

testing, read the section on the FOA Guide on OTDRs.)

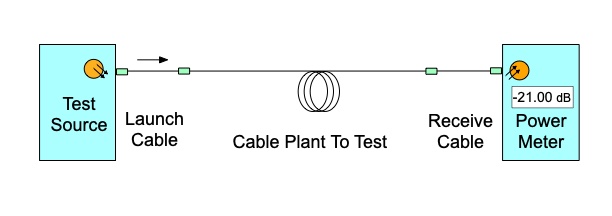

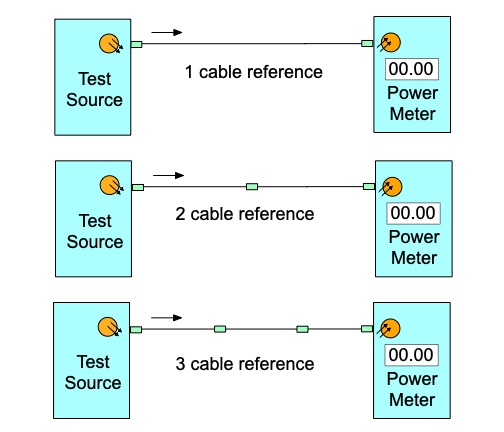

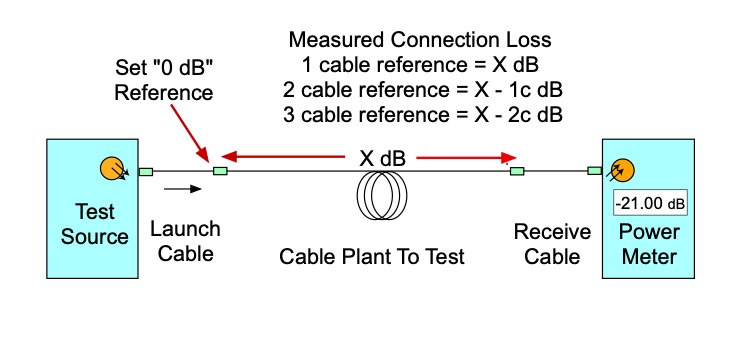

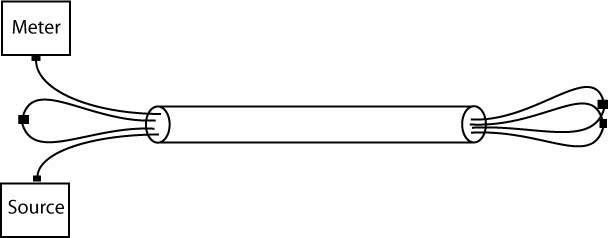

- Reference Cables For Insertion Loss Testing (see diagram above)

- Insertion loss testing may

require one,

two or three reference cables, depending on

the test performed and the appropriate mating

adapters for the connectors.

The 1 cable reference is used when the connector type on the instruments

matches the connectors on the cable plant, e.g. both use SC connectors.

After setting the 0 dB reference, the meter is disconnected and a

receive cable attached to it. The source launch reference cable is

connected to one end of the cable to be tested, the receive reference

cable and meter to the other end, and a measurement of loss is made.

This method is generally the preferred method of testing loss.

Note: Once the 0 dB reference is set, one should not disconnect the

launch cable from the source. Doing that will change the 0 dB reference

set and will require setting the 0 dB reference again.

The 2 cable reference can be used when the connectors on the instruments

and the cable plant do not match, e.g. SC connectors on the instruments

and LC on the cable plant. The reference cables will be hybrid cables,

SC on one end and LC on the other end. After setting the reference, the 2

cables are disconnected at the middle connection, attached to the cable

being tested and the loss measured.

The 3 cable method is used when the connectors on the instruments and

the cable plant do not match and/or the connectors on the cable plant

are plug/jack connectors such as the MPO connector with alignment pins

on one connector and holes on the mating connector. Here the two cables

on the ends are hybrid cables with connectors on one end to mate to the

instruments and connectors on the other end to mate with the 3rd

reference cable. The 3rd reference cable is a short cable with

connectors that are identical to the cable plant being tested. After the

0 dB reference is set using all 3 cables, the center cable is replaced

by the cable plant to be tested and the loss measured. This is sometimes

called a "cable substitution test."

The cable plant loss you measure will

depend on the reference method you use. The 2 cable method includes one

connection between reference cables when you set the 0 dB reference and

the 3 cable method includes two connections. The loss you measure with

the 2 and 3 cable reference methods will be reduced by the loss of the

connections included when setting the 0 dB reference.

Note: "1 c" is the loss of the connection when setting a 0 dB reference

with 2 cables and "2c" is the loss of the 2 connections included when

using the 3 cable reference method.

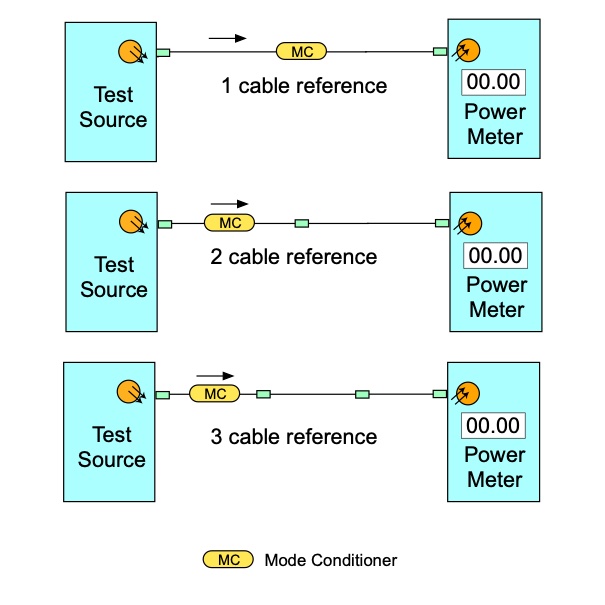

If the test requires mode

conditioning, such as with multimode fiber requiring a mandrel wrap or

encircled flux (EF) launch condition, the mode conditioning is done in

the launch cable attached to the source. Some multimode LED sources are

specified for EF launch and do not require mode conditioning.

- Reference cables for

insertion loss testing with a light source and power

meter are typically 1-3 meters long, with fiber and

connectors matching the cables to be tested.

- (OTDR reference/launch cables

are also used to isolate the large reflectance from

the instrument connector as well and need to be much

longer, typically ~20-100 meters for multimode and ~1

km for singlemode.)

- The

launch

and receive cables must be made with fiber

that is the same as the fiber in the cable plant being tested and

connectors matching the cables to be tested

and

terminated carefully to ensure low loss.

- The accuracy of the insertion loss

measurement will depend on the reference cables, since they will be mated to the

cable under test and the connection loss is measured

against the connector on the reference cable. To

provide reliable measurements, launch and receive

cables must be in good condition and kept very

clean. They can easily be tested against each other

to insure their performance. Connector mating

adapters are used to connect the cables under test

to the launch and receive cables. Only the highest

performance bulkhead splices should be used, and

their condition checked regularly, since they are

vitally important in obtaining low loss connections.

The quality and cleanliness of

the connectors on the launch and receive cables is

one of the most important factors in the accuracy of

loss measurements. Always test reference cables by

the patchcord or single ended method (FOTP-171,

reversing the cables to test connectors on both

ends) to make sure they are in good condition before

you start testing other cables with them.

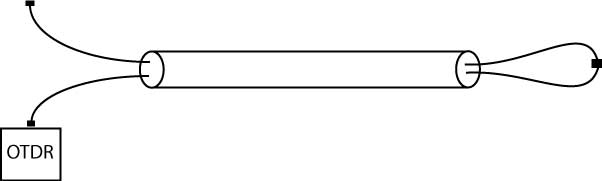

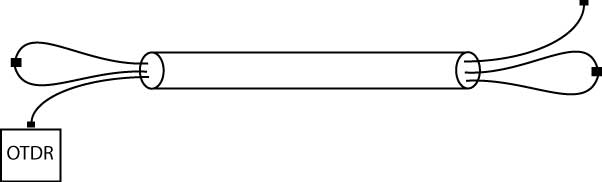

Reference Cables For OTDR Testing

OTDR testing can be done with one or two reference cables. Each cable has a different purpose.

The

OTDR launch cable is used to overcome the "dead zone" of the OTDR caused

by the high power test pulse overloading the receiver circuitry. So the

launch cable must be long enough to allow the OTDR circuitry to recover.

This varies according to the range of the OTDR, the width of the test

pulse and the signal processing, but should be fairly long. For

singlemode long distance tests, at least a 1 km launch cable is

recommended. For short distance tests, like FTTH cables using high

resolution OTDRs, the cable can be as short as 50-100 meters. Multimode

cables are always short, so a cable of 50-100 meters is usually

adequate.

The purpose of the receive reference cables is to test the connection with the

connector on the end of the cable under test. That leads to the

requirement for a receive reference cable on the far end, a cable

sometimes called a "tail cord," a strange name from international

standards - does that make the launch cable the "head cord"?

Some OTDR tests are done with only

a launch cable if the test is to verify splices in a cable being

installed and segments spliced together and there is no connector on the far end..

Requirements For Reference Cables

- Fiber type matches fiber in the cable plant being measured

- Connectors can mate with

instruments and connectors on cable plant which may require hybrid

cables for 2 or 3 cable reference methods

- Cables for insertion loss measurements should be 1-3 meters long.

- Cables for OTDR testing should

be sufficiently long for the launch cable to extend beyond the OTDR dead

zone under test conditions and the receive cable be long enough to be

easily seen by the OTDR.

- Reference cables are low loss when measured against each other

- Testing requires compatible connector mating adapters

Fiber Type

The fiber type must match the type of fiber in the cable plant.

Singlemode reference cables will generally be G.652 fiber or G.657

bend-insensitive fiber. If the cable plant is very long and uses some

version of dispersion shifted fiber, the only effect of using G.652

fiber for reference cables is a small mismatch loss at the connections

on the ends. Multimode fiber is more sensitive, but while most cable

plants use 50/125 fiber and any version of 50/125 fiber can be used

(OM2/3/4/5), there are still cable plants using 62.5/125 multimode fiber

which cannot be tested with reference cables with any other fiber due

to the large mismatch losses, up to ~4 dB when going from 62.5/125 to

50/125 fiber. See FOA Guide page on mismatched fiber losses.

Recent updates in standards have approved using

bend-insensitive (BI) fibers for reference cables.With multimode cable

plants, virtually all recent installations use BI fiber anyway, so using

BI fiber reference cables is correct. Singlemode BI fiber is mostly

used for patchcords and for new high-density microcables and high fiber

count cables, but there appears to be no problem mating BI and regular

fiber for testing purposes.

Connectors And Mating Adapters

Reference cables must have connectors that can mate to the connectors on

the test equipment and cable plant under test. Some test equipment hs

fixed connectors (e.g. SC) while others have modular connector adapters

that allow changing the style of connectors. The big problem is often

the test equipment has SC conenctors, or even modular connectors for any

connector with a 2.5 mm ferrule, but many cable plants are now using LC

connectors with 1.25 mm ferrules. One solution is to use hybrid test

cables with SC connectors on one end and LC connectors on the other. Set

the reference with 2 cables and record the test method with the loss

data and/or compensate for the reference method.

Adapters that convert from SC to LC connectors are

available but they have some problems when used with testing. Some a

simple mechanical adapters, with mating sleeve with different hole sizes

on each side, These cab be highly variable in loss, especially with

singlemode fiber. Other adapters have fiber inside the adapter and are

more consistent, but they require compensation when used with test

equipment. Hybrid cables and a 2 or 3 cable reference method may provide

better results.

- "Special

Quality" Reference Cables

- Standards

groups have tried to specify the quality of

reference cables in terms of tight tolerance

components like the fiber and connectors.

Standards

which call for special reference quality

test cables specify specify cables with low loss connections. The

best recommendation for qualifying reference

cables

is to choose cables with low loss, tested

"single-ended" per cable test standard FOTP-171.

- Mode

Conditioning

Mode

conditioning is generally required for multimode and

singlemode launch cables attached to a source. Multimode

cables generally use a mandrel wrap mode conditioner (see

here and here)

and a LED source but special modal conditioning patchcords

are available. Singlemode fiber just needs a 30mm loop to

ensure the launch cable is singlemode.

- Mating Adapters

Connector-to-connector mating adapters are

used to

connect reference cables to the cables being

tested. For ferrule type connectors, the mating adapter is the critical

alignment device for the ferrules and is an important component in the

loss testing of a connection.

Only the highest quality mating adapters

should be

used for testing, as they are a factor in

loss also.

Inexpensive adapters generally have plastic

mating

sleeves to align the connector ferrules

which wear

out quickly, causing high loss with even

good

connectors. Use only mating adapters with

metal or

preferably ceramic mating sleeves which are

specified for both multimode and singlemode

connectors.

How Long Do Reference Cables And Mating Adapters Last?

Multiple matings will cause connectors to wear on the end

face and sometimes along the ferrules also. Most connectors are good for

hundreds or even thousands of matings as long as they are cleaned

regularly. Microscope inspection will show scratches or scuffing on the

connector endface, indicating wear may be a problem. Testing with a

single-ended loss test against each other with new mating adapters and

comparing results taken when they were new or last tested will show if

they are a problem. Mating adapters are harder to test, so they should

also be cleaned regularly using the probe type cleaners recommended for

jacks in patch panels and discarded after a number of matings - perhaps

500 for metallic alignment sleeves or several thousand for ceramic

alignment sleeves. If you notice connector ferrules getting dirty on the

side of the ferrule, change the mating adapters then.

Caring For Reference Cables

It

is very important to keep reference cables in good condition as they

are a very important factor in making accurate and repeatable fiber

optic measurements. Here are some guidelines for their care:

- Inspect and clean regularly

- Test against each other for loss

- Keep protective caps on connectors

- Store in safe place to prevent damage

- Do not kink, twist or otherwise stress

cables

- Repair or replace when needed

Field

Use - Creating Reference Cables When You Don't Have Them

You

should always use the proper cables for reference cables, but if

you

find yourself in the field without a set of

reference cables or your reference cables

are worn and causing high loss measurements, you can always use

patchcords or

other cables, even fibers in a cable you are

testing, as reference cables. Remember this

adds uncertainty to the measurements due to the condition

of the connectors and length of fiber.

OLTS

Testing

For a insertion loss testing of a multi-fiber cable with a meter and

source, you can use one fiber as a launch cable

and loop-back fibers from the far end of the

cable to test other fibers. You will need to take

the meter to the far end of the cable and calibrate

the output of the launch cable or use the 2-cable reference. It's easier to

do this with two sets of meters and sources, but can

be done with one.

Continue

looping

fibers back at the end of the cable. Remember each

loopback added includes the attenuation from two fiber

lengths and two connector losses!

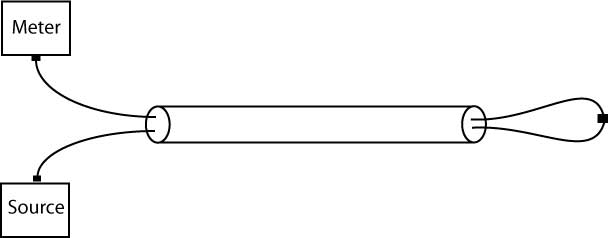

OTDR Testing

If

you are testing a multi-fiber cable that's

long enough to test with an OTDR and you have

already tested it with an OLTS (like standards

require) so you know the fiber is good, you

can use one of the fibers in the cable as a

launch cable. Set up as below and simply have

another tech connect up the fiber being used

as the launch cable to the other fibers to

test each of them. If you want to test from

one end by yourself, loopback from the far end

and then use the two fibers as the launch

cable to connect up to other fibers from the

same end as the OTDR (second drawing.) If you

have access to both ends, you can continue

looping back and get many fibers on one trace,

to the length capability of the OTDR.

Additional Reading

Testing

Installed Cable Plants

Accuracy

of fiber optic measurements

|