Overview

of Fiber Optic Instrumentation

Testing fiber optic components

and cable plants requires making several

measurements with the most common measurement

parameters listed in the Table below. Optical power,

required for measuring source power, receiver power

and, when used with a test source, loss or

attenuation, is the most important parameter and is

required for almost every fiber optic test.

Backscatter and wavelength measurements are the next

most important and bandwidth or dispersion are of

lesser importance. Measurement or inspection of

geometrical parameters of fiber are essential for

fiber manufacturers. And troubleshooting installed

cables and networks is required.

Fiber Optic Testing

Requirements

| Test

Parameter |

Instrument |

|

Optical Power

(Source

Output, Receiver Signal Level)

|

Fiber Optic Power Meter |

|

Attenuation

or Loss of Fibers, Cables &

Connectors

(Insertion Loss)

|

FO Power Meter &

Source or

OLTS (optical loss test set)

|

| Source

Wavelength, Spectral Width |

FO Spectrum Analyzer |

|

Backscatter For

Loss, Length and Fault

Location)

|

Optical Time Domain Reflectometer(OTDR) |

| Fault

Location |

OTDR,

Visual Cable Fault

Locator

|

|

Bandwidth /

Dispersion

(MM:Modal &

Chromatic,

SM: Chromatic and Polarization Mode)

|

Dedicated

Bandwidth Testers |

| Reflectance |

OTDR,

OCWR (Optical Continuous Wave

Reflectometer) |

Fiber

Geometry

(Core and cladding diameter, concentricity,

etc.) |

Various

mechanical and optical inspection tools |

Standard Test Procedures

Most test procedures for fiber

optic component specifications have been standardized

by national and international standards bodies,

including TIA

in the US and ISO/IEC internationally. FOA

has its own standards for basic tests.

Procedures for measuring absolute optical power, cable

and connector loss and the effects of many

environmental factors (such as temperature, pressure,

flexing, etc.) are covered in these procedures.

In order to perform these tests,

the basic fiber optic instruments are the FO power

meter, test source, OTDR, optical spectrum analyzer

and an inspection microscope. These and some other

specialized instruments are described below.

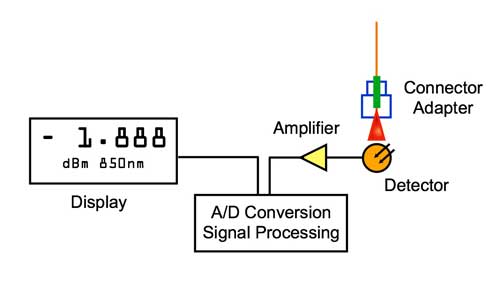

Fiber Optic Power Meters

Fiber optic power meters measure

the average optical power out of an optical fiber.

Power meters typically consist of a solid state

detector (silicon for short wavelength systems,

germanium or InGaAs for long wavelength systems),

signal conditioning circuitry and a digital display of

power. To interface to the large variety of fiber

optic connectors in use, some form of removable

connector adapter is usually provided.

Power meters are calibrated to

read in dB referenced to one milliwatt of optical

power. Some meters offer a relative dB scale also,

useful for loss measurements since the reference value

may be set to "0 dB" on the output of the test source.

Occasionally, lab meters may also measure in

linear units (milliwatts, microwatts and nanowatts.)

Since all semiconductor detectors have a sensitivity

that varies with the wavelength of the light it is

measuring, power meters are calibrated at the typical

wavelengths used in fiber optics, 850, 1300 and 1550

nm. Meters for POF systems are usually calibrated at

650 and 850 nm, the wavelengths used in POF systems.

Power meters cover a very broad

dynamic range, over 1 million to 1 or 60 dB. Although

most fiber optic power and loss measurements are made

in the range of 0 dBm to -50 dBm, some power meters

offer much wider dynamic ranges. For testing analog

CATV systems or fiber amplifiers, on needs special

meters with extended high power ranges up to +20 dBm

(100 mW). Although no fiber optic systems operate at

very low power, below about -50 dBm, some lab meters

offer ranges to -70 dBm or more, which can be useful

in measuring optical return loss or spectral loss

characteristics with a monochromator source.

Power meters measure the time

average of the optical power, not the peak power, so

the meters are sensitive to the duty cycle of an input

digital pulse stream. One can calculate peak power if

one knows the duty cycle of the input, by dividing the

average power by the duty cycle. For most loss

measurements, one uses a test source with CW (steady

state) or 2 kHz pulsed output. As long as the source

modulation doesn't change, no compensation needs to be

made. When testing link transmitter power or receiver

sensitivity, it is necessary to establish a standard

test pattern, generally a 50% duty cycle, called a

square wave, to allow accurate measurement of

transmitter output or receiver sensitivity. See

measuring power.

FO power meters have a typical

measurement uncertainty of +/-5% measuring absolute

optical power, when calibrated to transfer standards

provided by national standards laboratories like the

US National Institute of Standards and Technology

(NIST). Sources of errors are the variability of

coupling efficiency of the detector and connector

adapter, reflections off the shiny polished surfaces

of connectors, unknown source wavelengths (since the

detectors are wavelength sensitive), nonlinearities in

the electronic signal conditioning circuitry of the FO

power meter and detector noise at very low signal

levels. Since most of these factors affect all power

meters, regardless of their sophistication, expensive

laboratory meters are hardly more accurate that the

most inexpensive handheld portable units. Meters

should be recalibrated frequently by labs with NIST

traceable calibration systems.

See

calibration.

Measuring loss, which is a

relative measurement over a much smaller range of

optical powers has a much lower uncertainty. Generally

the instrument uncertainty is much smaller than the

uncertainty caused by the fiber optic components and

test setup.

(Photo courtesy Advanced Fiber

Solutions)

Fiber Optic Test Sources

In order to make measurements of

optical loss or attenuation in fibers, cables and

connectors, one must have a test source as well as a

FO power meter. The test source must be chosen for

compatibility with the type of fiber in use

(singlemode or multimode with the proper core

diameter) and the wavelength desired for performing

the test. Most sources are either LED's or lasers of

the types commonly used as transmitters in actual

fiber optic systems, making them representative of

actual applications and enhancing the usefulness of

the testing. Some tests, such as measuring spectral

attenuation of fiber requires a variable wavelength

source, which is usually a tungsten lamp with a

monochromator to vary the output wavelength.

Typical wavelengths of sources

are 650 or 665 nm (LEDs for plastic fiber), 850 and

1300 nm (LEDs for multimode fiber) and 1310 nm and

1550 nm (lasers for singlemode fiber). LED's are

typically used for testing multimode fiber and lasers

are used for singlemode fiber, although there is some

crossover, especially in high speed LANs which use

multimode fiber with lasers and the testing of short

singlemode jumper cables with LED's. The source

wavelength can be a critical issue in making accurate

loss measurements on long links, since attenuation of

the fiber is wavelength sensitive especially at short

wavelengths. Thus all test sources should be

calibrated for wavelength.

Test sources almost always have

fixed connectors. Hybrid test jumpers with connectors

compatible with the source on one end and the

connector being tested on the other must be used as

reference cables. This may affect the type of

reference setting mode used for loss testing.

Other source-related factors

affecting measurement accuracy are the stability of

the output power and the modal distribution launched

into multimode fiber. For extremely accurate

measurements, the source may need optical feedback

stabilization to maintain output power at a precise

level for long times required for some measurements.

Industry standards have requirements or

recommendations on the modal output of test sources

for multimode fiber that are aimed at the

manufacturers of the test sources. Mode scramblers,

filters and strippers may be required to adjust the

modal distribution in the fiber to approximate actual

operating conditions.

(Photo courtesy Advanced Fiber Solutions)

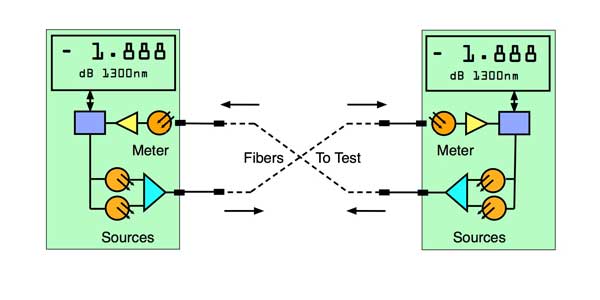

Optical Loss Test Sets/Test

Kits

The optical loss test set is an

instrument formed by the combination of a fiber optic

power meter and source which is used to measure the

loss of fiber, connectors and connectorized cables.

Early versions of this instrument were called

attenuation meters. A test kit has a similar purpose,

but is usually comprised of separate instruments and

includes accessories to customize it for a specific

application, such as testing a FO LAN, telco or CATV.

The OLTS may have several

optional features that affect its use. Some have

individual source outputs and meter inputs like a

separate power meter and test source, but may have two

wavelengths from one source output (MM: 850/1300,

SM:1310/1550.) Some offer bidirectional testing on a

single fiber and some have two bidirectional ports.

Some manufactures of premises copper cabling testers

offer modules to convert these testers to an OLTS,

allowing fiber and copper testing with one instrument.

The combination OLTS instrument

which contains both a meter and source may be less

convenient than an individual source and power meter,

since the ends of the fiber and cable are usually

separated by long distances, which would require two

OLTSs instead of one source and one meter. An OLTS

often has a single port for bidirectional measurements

also. This port usually has a fixed connector which

may cause problems when testing cable plants with

connector styles different than those on the

instrument, requiring a 2- or 3-cable reference for

loss testing which may not meet industry standards.

The bidirectional port may also have problems meeting

standards for modal power distribution in multimode

fibers. Ask the OLTS manufacturer about these issues

before purchasing an instrument.

Note: OLTS sometimes

display loss in a different way than if you test

with a meter and source. With a meter and source, if

you set the reference value for "0dB" at "0" and

test cables for loss, loss will be displayed as a

negative number, since lower optical powers (after

the loss) are more negative numbers. Some but not

all OLTS will display the loss as a positive number

which can be confusing to those who learn to test

using a source and power meter.

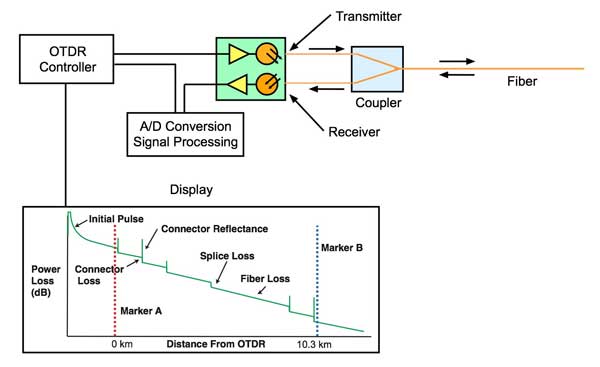

Optical Time Domain

Reflectometer

The optical time domain

reflectometer (OTDR) uses the phenomena of fiber

backscattering to characterize fibers and installed

cables, find faults and optimize splices. Since

scattering is one of the primary loss factors in fiber

(the other being absorption), the OTDR can send out

into the fiber a high powered pulse and measure the

light scattered back toward the instrument. The pulse

is attenuated on the outbound leg and the

backscattered light is attenuated on the return leg,

so the returned signal is a function of twice the

fiber loss and the backscatter coefficient of the

fiber.

If one assumes the backscatter

coefficient is constant, the OTDR can be used to

measure loss as well as locate fiber breaks, splices

and connectors. In addition, the OTDR gives a graphic

display of the status of the fiber being tested. And

it offers another major advantage over the source/FO

power meter or OLTS, in that it requires access to

only one end of the fiber.

The uncertainty of the OTDR

measurement is heavily dependent on the backscatter

coefficient, which is a function of intrinsic fiber

scattering characteristics, core diameter and

numerical aperture. It is the variation in backscatter

coefficient that causes many splices to show a "gain"

instead of the actual loss. OTDRs must also be matched

to the fibers being tested in both wavelength and

fiber core diameter to provide accurate measurements.

Thus many OTDRs have modular sources to allow

substituting a proper source for the application.

While most OTDR applications

involve finding faults in installed cables or

verifying splices, they are very useful in inspecting

fibers for manufacturing faults. Development work on

improving the short range resolution of OTDRs for LAN

applications and new applications such as evaluating

connector return loss promise to enhance the

usefulness of the instrument in the future.

OTDRs come in three basic

versions. Full size OTDRs offer the highest

performance and have a full complement of features

like data storage, but are very big and high priced.

MiniOTDRs provide the same type of measurements as a

full OTDR, but with fewer features to trim the size

and cost. Fault finders use the OTDR technique, but

greatly simplified to just provide the distance to a

fault, to make the instruments more affordable and

easier to use.

More

on OTDRs.

Visual Cable Tracers and Fault

Locators

Many of the problems in

connection of fiber optic networks are related to

making proper connections. Since the light used in

systems is invisible, one cannot see the system

transmitter light. By injecting the light from a

visible source, such as a LED or incandescent bulb,

one can visually trace the fiber from transmitter to

receiver to insure correct orientation and check

continuity besides. The simple instruments that inject

visible light are called visual fault locators.

If a powerful enough visible

light ,such as a HeNe or visible diode laser is

injected into the fiber, high loss points can be made

visible. Most applications center around short cables

such as used in telco central offices to connect to

the fiber optic trunk cables. However, since it covers

the range where OTDRs are not useful, it is

complementary to the OTDR in cable troubleshooting.

This method will work on buffered fiber and even

jacketed single fiber cable if the jacket is not

opaque to the visible light. The yellow jacket of

singlemode fiber and orange of multimode fiber will

usually pass the visible light. Most other colors,

especially black and gray, will not work with this

technique, nor will most multifiber cables. However,

many cable breaks, macrobending losses caused by kinks

in the fiber , bad splices etc. can be detected

visually. Since the loss in the fiber is quite high at

visible wavelengths, on the order of 9-15 dB/km, this

instrument has a short range, typically 3-5 km.

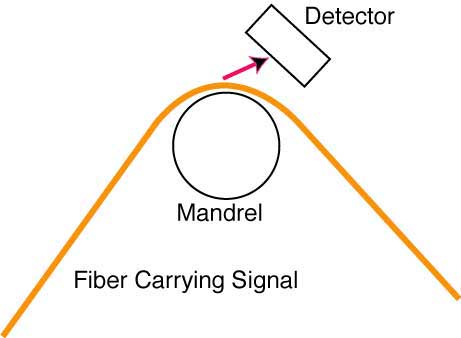

Fiber Identifiers

Telco technicians often need to

identify a fiber in a splice closure or at a patch

panel. If one carefully bends a singlemode fiber

enough to cause loss, the light that couples out can

also be detected by a large area detector. A fiber

identifier uses this technique to detect a signal in

the fiber at normal transmission wavelengths. These

instruments usually function as receivers, able to

discriminate between no signal, a high speed signal

and a 2 kHz tone. By specifically looking for a 2 kHz

"tone" from a test source coupled into the fiber, the

instrument can identify a specific fiber in a large

multifiber cable, especially useful to speed up the

splicing or restoration process.

Fiber identifiers can be used

with both buffered fiber and jacketed single fiber

cable. With buffered fiber, one must be very careful

to not damage the fiber, as any excess stress here

could result in stress cracks in the fiber which could

cause a failure in the fiber anytime in the future.

Measuring Fiber Bandwidth

Although fiber has a very high

bandwidth, some applications actually approach its

limits, requiring performance evaluation. Two factors

limit multimode fiber bandwidth: modal dispersion and

chromatic dispersion. Long singlemode links require

concern over chromatic dispersion or polarization-mode

dispersion. Specialized instruments are available for

testing each of these specifications but are expensive

and rarely used outside the laboratory.

O/E and E/O Converters

Optical to electrical (O/E) and

electrical to optical (E/O) converters have other uses

besides testing fiber bandwidth. O/E converters can be

used with high speed oscilloscopes to analyze pulses

in fiber optic links to see if the waveforms are of

the proper shape. This means measuring rise and fall

times of the pulse and the depth of modulation (the

difference between the peak power of the pulse and the

lowest power reached between pulses. They can be used

for testing lasers and LEDs used in transmitters and

link dispersion in long links. E/O converters are used

to test receivers for bandwidth and margin, usually in

conjunction with a bit error rate tester and

attenuator.

Optical Continuous Wave

Reflectometers (OCWR)

The OCWRor reflectance

tester was originally proposed as a special

purpose instrument to measure the reflectance

or optical

return loss of connectors installed on patchcords or

jumpers. Unfortunately, its purpose became muddled

between conception and inception. As actual

instruments came on the market, they had much higher

measurement resolution than appropriate for the

measurement uncertainty (0.01 dB resolution vs. 1 dB

uncertainty), leading to much confusion on the part of

users as to why measurements were not reproducible. In

addition, several instruments were touted as a way to

measure the optical return loss of an installed cable

plant, obviously in ignorance of the fact that they

would also be integrating the backscatter of the fiber

with any reflections from connectors or splices. Since

the measurement of return loss from a connector can be

made equally well with any power meter, laser source

and calibrated coupler, and an OTDR is the only way to

test installed cable plants for return loss, the OCWR

has seen little use in fiber optic testing.

Test Equipment For Long

Distance Fiber Links

Long distance fiber links may

suffer from chromatic dispersion or polarization mode

dispersion. Generally they also use DWDM so need

testing for spectral attenuation. These tests use very

specialized instruments. Read more about these tests here.

Optical Fiber Analyzers

There are many parameters of

optical fiber that require testing by the

manufacturer. These include attenuation (as a function

of source wavelength), bandwidth/dispersion, numerical

aperture and all the physical dimensions such as core

and cladding diameter, ovality, and concentricity.

Automated laboratory instruments are available to

measure all these parameters automatically, but many

fiber manufacturers prefer to build their own. The

most difficult part of fiber measurements is the fact

that subtle differences in test setup and

instrumentation can cause differences in measured

values.

Visual Inspection with

Microscopes

Optical (L) and video (R) microscopes

Cleaved fiber ends prepared for

splicing and polished connector ferrules require

visual inspection to find possible defects. This is

accomplished using a microscope which has a stage

modified to hold the fiber or connector in the field

of view. Fiber optic inspection microscopes vary in

magnification from 30 to 800 power, with 30-100 power

being the most widely used range. Cleaved fibers are

usually viewed from the side, to see breakover and

lip. Connectors are viewed end-on or at a small angle

to find polishing defects such as scratches.

Fiber Optic Talksets

While technically not an

measuring instrument, FO talksets are useful for FO

installation and testing. They transmit voice over

fiber optic cables already installed, allowing

technicians splicing or testing the fiber to

communicate effectively. Talksets are especially

useful when walkie-talkies and telephones are not

available, such as in remote locations where splicing

is being done, or in buildings where radio waves will

not penetrate.

The way to use talksets most

effectively is to set up the talksets on one fiber (or

pairs appropriate) and leave them there while all

testing or splicing work is done. Thus, there will

always be a communications link between the working

crew, which facilitates deciding which fibers to work

with next. The continuous communications capability

will greatly speed the process.

Recent developments in talksets

include talksets for networking multi-party

communications, especially helpful in restoration, and

system talksets for use as intercoms in installed

systems. There are also combination testers and

talksets.

There are no standards for the

way talksets communicate. Some use simple AM

transmission, some FM and some proprietary digital

schemes. Thus no two manufacturers' talksets can

communicate with each other. Bellcore has addressed

this matter in a technical advisory that proposes a FM

method at 80 and 120 kHz, but it will take years

before a standard has been set and manufacturers offer

compatible instruments.

Attenuators

Attenuators are used to simulate

the loss of long fiber runs for testing link margin in

network simulation in the laboratory or self-testing

links in a loopback configuration. In margin testing,

variable attenuators are used to increase loss until

the system has a high bit error rate. For loopback

testing, an attenuator is used between a single piece

of equipment's transmitter and receiver to test for

operation under maximum specified fiber loss. If

systems work in loopback testing, they should work

with a proper cable plant. Thus many manufacturers of

network equipment specify a loopback test as a

diagnostic/troubleshooting procedure.

Attenuators can be made by gap

loss, or a physical separation of the ends of the

fibers, inducing bending losses or inserting

calibrated optical filters. Both variable and fixed

attenuators are available, but variable attenuators

are usually used for testing. Fixed attenuators may be

inserted in the system cables where distances in the

fiber optic link are too short and excess power at the

receiver causes transmission problems.

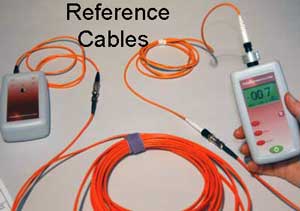

Reference Test Jumper Cables

and Mating Adapters

In order to test cables in an

insertion loss test, one needs to establish test

conditions. This requires reference launch jumper

cables to connect the test source to the cable under

test and receive cables to connect the fiber optic

power meter. For accurate measurements, the launch and

receive cables must be made with fiber and connectors

matching the cables to be tested and terminated

carefully to ensure low loss. To provide reliable

measurements, launch and receive cables must be in

good condition and kept very clean. They can easily be

tested against each other to insure their performance.

Connector mating adapters are used to connect the

cables under test to the launch and receive cables.

Only the highest performance bulkhead splices should

be used, and their condition checked regularly, since

they are vitally important in obtaining low loss

connections.

Additional Reading

Testing

Installed Cable Plants

Accuracy

of fiber optic measurements