Fiber Optic Cable Installation - Midspan Access

Simplifying

Installation Of Drops

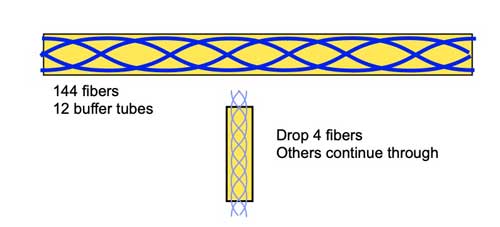

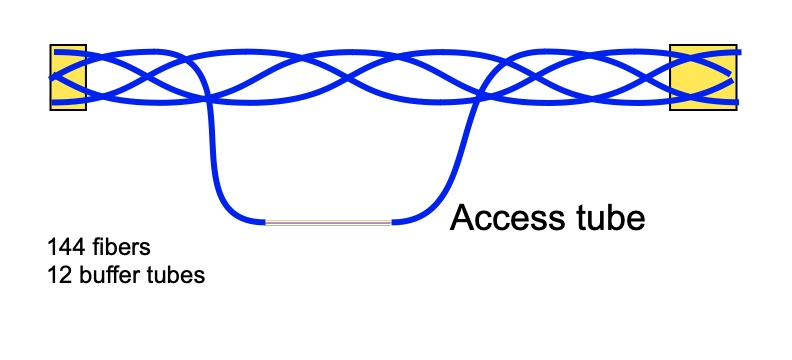

Many

installations involve splitting the fibers in a cable or

dropping a small fiber count cable from a large backbone

cable. Backbone cables of 144-288 fibers are common and

larger ones are becoming more common too. Drop cables are

often only 2-12 fibers, meaning most fibers are continuing

straight through the drop point. Midspan access involves

opening the cable by removing the jacket and strength

members, opening the buffer tube and splicing only the

fibers being dropped at that point. The untouched buffer

tubes from the opened cable are carefully rolled up and

stored in the same splice closure as the fibers that will

be separated and spliced to a drop cable.

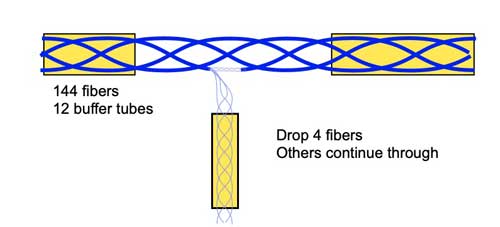

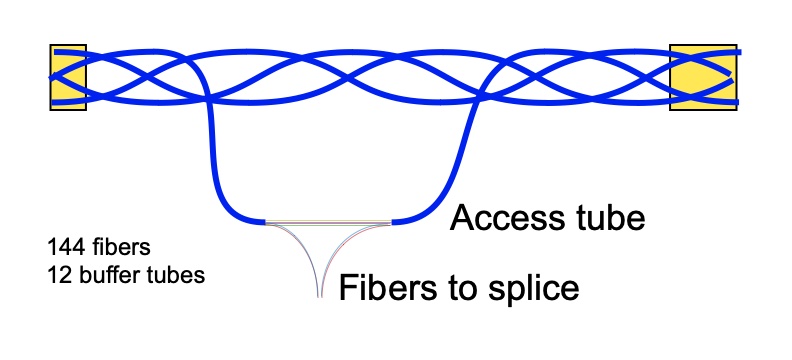

If there is a method of splicing only the 4 drop fibers

instead of the 144 fibers, we will only have 4 splices

instead of 144 or 146 depending on the architecture of our

system. The difference is according to how the drop is

configured.

If you are building a star network where every drop links

back to the origin of the network, you will splice 4

fibers in the cable to the drop cable, leaving 4 splices

on 4 fibers (instead of 144 splices if the backbone cable

is cut and respliced.

If you are building a ring network, you may only be

splicing two fibers going to the drop and two that are

continuing along the ring network.

All this may seem obvious but in actual practice requires

some knowledge, skills and careful workmanship. To do a

proper job. Fortunately, manufacturers of cables and tools

have good information available online on how to do it,

and FOA Master Instructor Joe Botha has provided FOA with

a application

note on how midspan access is done in his classes

also.

The Process

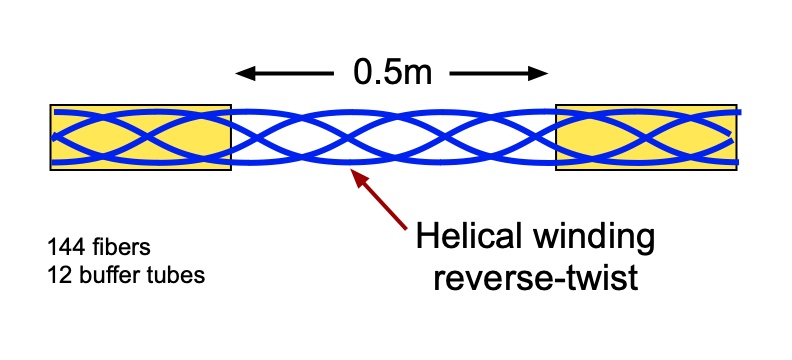

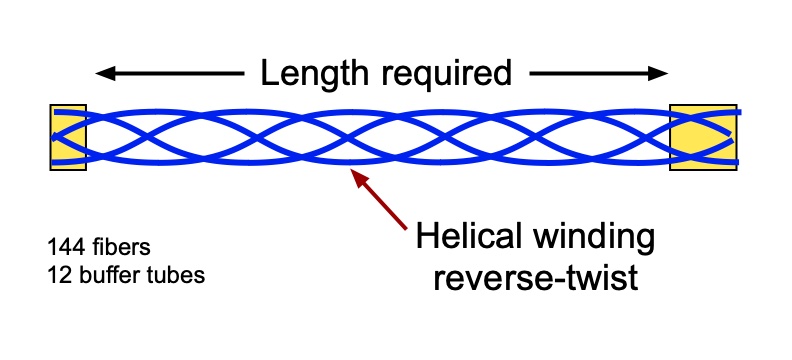

The basic process is simple. We will look at a loose tube

cable but processes exist for ribbon cables also,

involving splitting ribbons to access the drop fibers.

Following the cable manufacturer's directions, remove a

short length of cable jacket to find the reversal point

for the helical winding of the buffer tubes. The reversal

point will the center of the opening for access to make

unwinding tubes neater. Find the ripcords to use for

removing a longer length of the jacket.

Note:

If you open up on a reverse twist and end on reverse

twists, the tubes will enter the closure as straight as

an arrow. And

where the reverse twist philosophy is ignored, the tubes

entering a closure, will need to be forced into position

and will be under bending stress. On some

cables, you may be able to find the reversal point by

looking at the cable jacket - if the jacket is thin

enough that the location of the tubes shows through

the cable jacket. Some manufacturers also mark the

cable to help locate the reversal point.

You must remove the jacket of the cable for a

specified length according to the cable type and splice

closures used. After removing the cable jacket, you remove

unnecessary binder tapes and water blocking tapes and

strength members, leaving enough of the stiff central

member on both ends to attach to the splice closure.

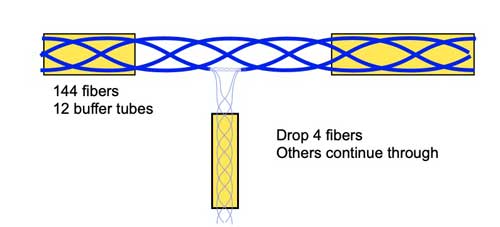

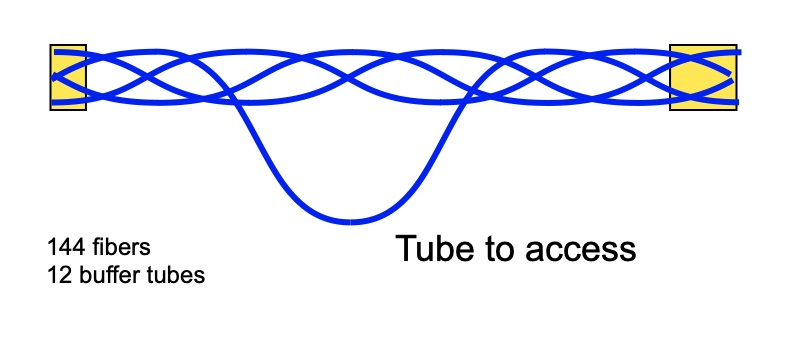

Identify the tube with the fibers to be spliced to the

drop cable and set aside while carefully coiling the other

tubes for storage in the closure.

Separate the buffer tube that will be opened from the

tubes that will pass through the splice closure. They will

be secured in the closure.

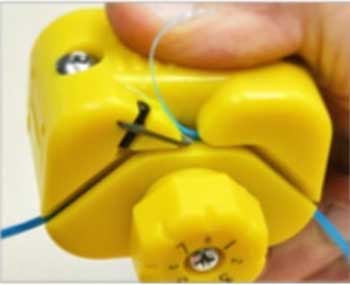

To open the buffer tube, you need a midspan access tube

that shaves off a section of the tube to allow removal of

the fibers without damaging them. Here two types of Miller

tools that shave the tube:

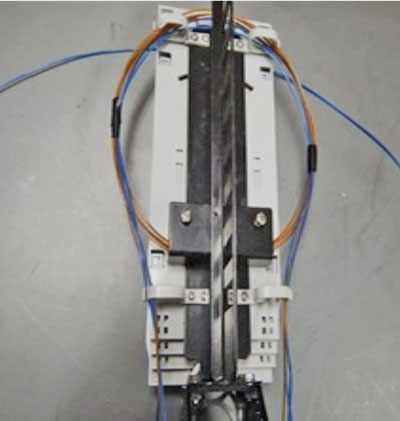

After

shaving the tube and removing the fibers - count carefully

to ensure you remove all the fibers! - you can cut the

tube off to have bare fibers only for the length you need

to splice on the drop cable. Secure the tube to the splice

tray. All these fibers will be placed in a splice tray for

safe storage but only the fibers being dropped will be cut

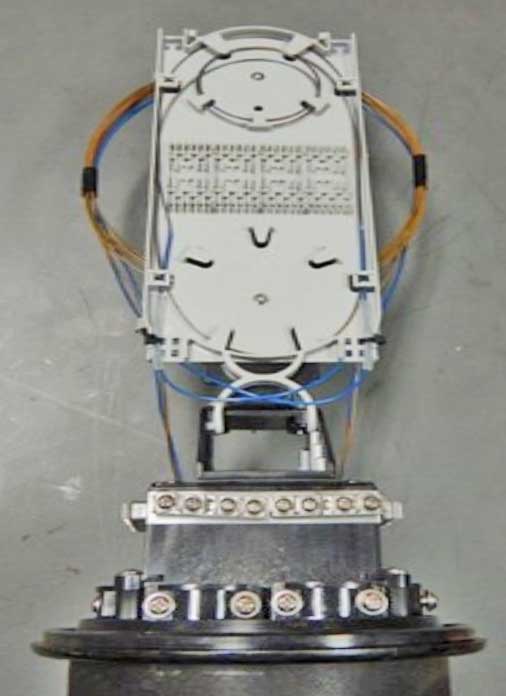

and spliced to the drop cable. This is what the closure

will look like, ready for splicing the drop cable.

The

closure is ready for the addition of the drop cable and

splicing fibers.

Note: The illustration is done with OSP loose-tube

cable but the process is similar with ribbon cables

except pass-through ribbons need protecting in a

splice tray. The same technique can also be used with

tight-buffer distribution cable for premises networks.

Search online for "midspan access" to find lots of

application notes and videos on the subject. Or talk to

your fiber optic cable vendors.

Application

note - hands-on midspan access

More

on Outside Plant Construction and Installation

Table

of Contents: The FOA Reference Guide To Fiber Optics

|