Testing

The Installed Fiber Optic Cable Plant - 5 Standard Ways

Abstract:

We often are asked questions about testing installed

fiber optic cables that indicate the industry standards

are confusing, have little information on measurement

accuracy and no guidelines for troubleshooting. This web

page is an attempt to clear up some of this confusion.

But remember, as Bob Metcalfe, co-inventor of Ethernet,

says, "Standards are wonderful, because we have so many

to choose from!"

Testing Fiber Optic Cables

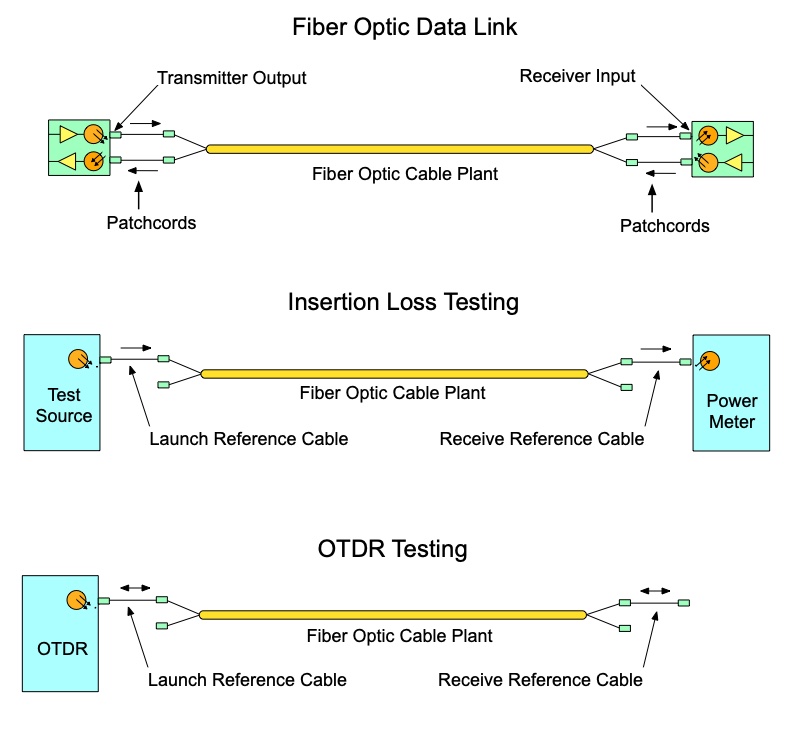

In order to test

the fibers in a fiber optic cable with a power meter and source or with an OTDR, one

needs to

establish test conditions. The test

conditions should be similar to how the actual cable plant will be used

when communications equipment is connected (see drawing below.) For

insertion loss

testing, this requires reference launch

jumper

cables to connect the test source to the

fiber in the cable under

test and receive cables to connect the fiber

optic

power meter. For OTDR testing, this requires

a reference launch cable to connect the OTDR to the fiber in the cable

under test and a receive cable at the far end of the fiber.

6 Ways? It has

been said occasionally that there are in fact 6 ways -

if you include single-ended

testing used for patchcords. That's true, and this

method is used to troubleshoot bad connectors on cables

by testing each end separately, but the loss of a cable

plant must be done "double ended" as described here.

Standards Update: The old

TIA OFSTP-14 was replaced by a new ISO standard. The TIA

has adopted IEC 61280-4-1 as the replacement of

OFSTP-14. Most of the two documents is the same, with

some important exceptions.

• For insertion

loss, three reference methods are are still approved,

but the nomenclature is different - no more confusing "Method A, B

or C" designations- it's now 1, 2 or 3 reference cables.

• OTDR testing is

now an approved second tier test method as long as you

use both launch and receive cables.

• Reference test

cables with "reference grade connectors" are

recommended.

• Methods are given

for testing and verifying the loss of reference test

cables.

• For multimode

modal control, CPR with a mandrel wrap is gone, at least

for 50/125 fiber at 850nm, replaced by "Encircled

Flux," a complex

method of measuring the source output, but the

old mandrel wrap is a close approximation of EF launch conditions.

Most of the other changes are nomenclature. In the meantime,

continue testing as usual.

There are five ways listed in various

international standards from the EIA/TIA and ISO/IEC to

test installed fiber optic cable plants. Three of these methods use test

sources and power meters to make the measurement (called insertion loss testing), while

the fourth and fifth use an OTDR. The best way to

understand them is to look at the diagrams above and below.

The source/power meter method, generally

called "insertion loss," approximates the way the actual

network uses the cable plant, so one would expect the loss

to be similar to the actual loss seen by the network,

which is preferable. The OTDR is an indirect method, using

backscattered light to imply the loss in the cable plant,

which can have large deviations from insertion loss tests.

OTDRs are more often used to verify splice loss or find

damage to cables.

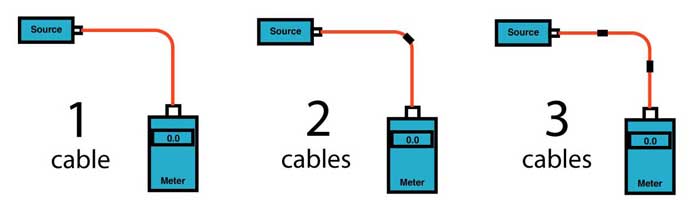

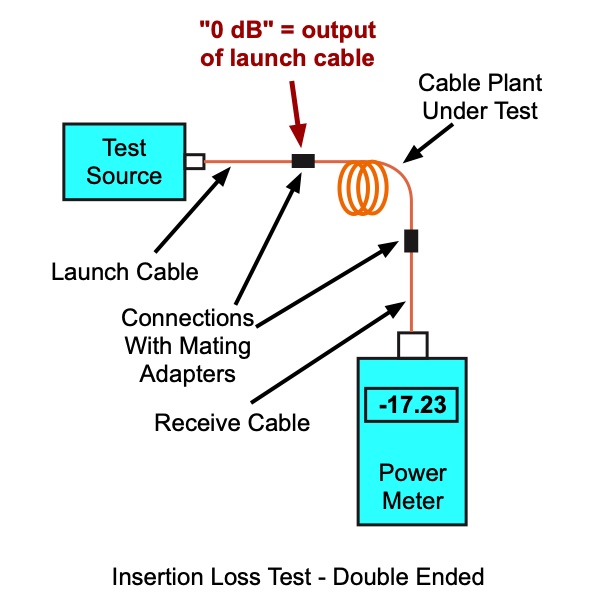

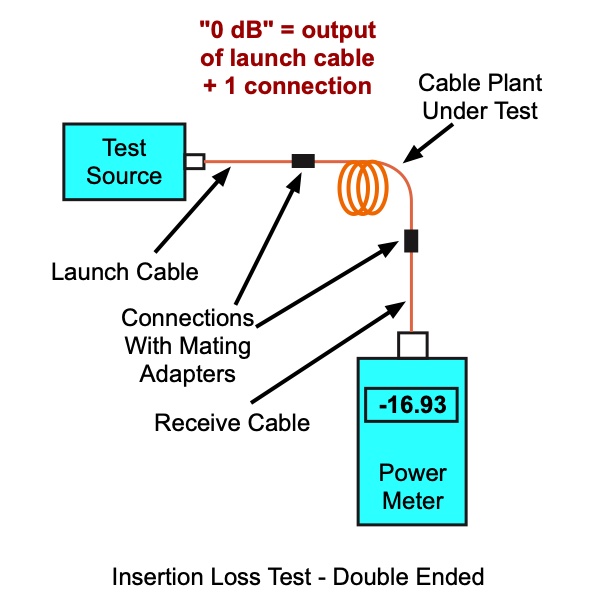

The differences in the three insertion loss

tests are in how we define the "0 dB" reference or no loss. All three

tests end up with the same test setup (Figure 1), but the

reference power can be set with one, two or three cables

as shown in the three setups below. The different methods of setting the 0 dB reference are needed because of the variety of fiber optic connectors on cables and test equipment.

All test methods have measurement uncertainty.

After we explain the methodology, we will examine the

measurement uncertainty.

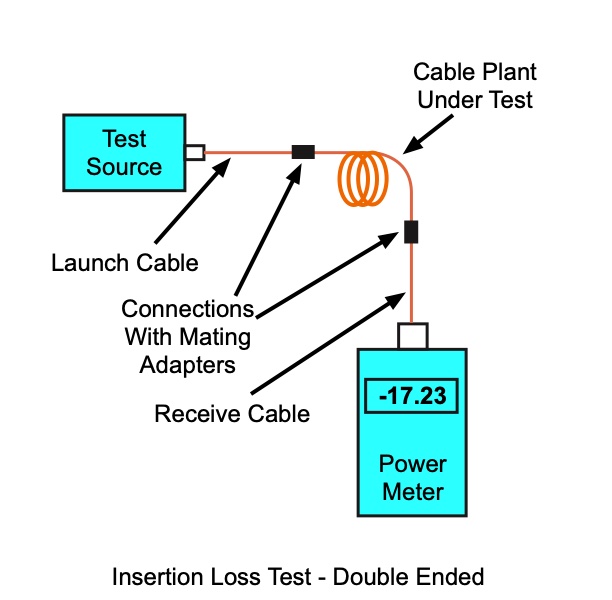

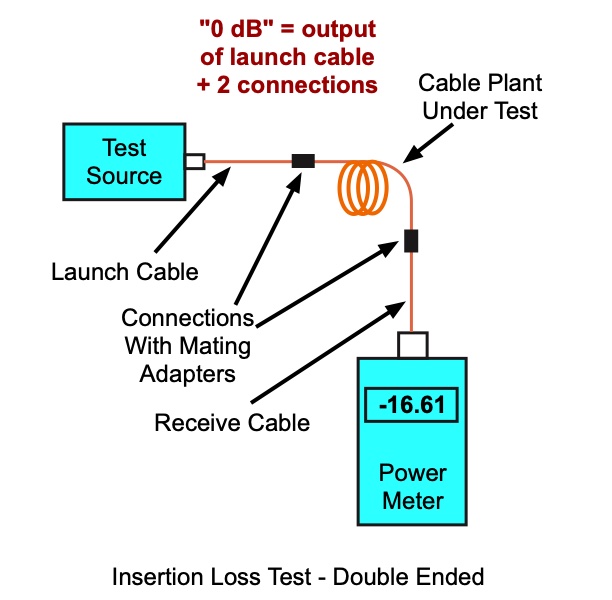

Insertion Loss - Double-Ended Cable Test

Per TIA

OFSTP-14 (Multimode) and OFSTP-7 (Singlemode)

(and similar international standards)

Insertion loss testing with a test source and power meter

simulates the way the cable plant will be used with an

actual link. The test source mimics the transmitter, the

power meter the receiver. But insertion loss testing

requires reference cables attached to the source and meter

to connect to the cable under test.

The insertion loss

test can use 1, 2 or 3 reference cables to set the “zero

dB loss” reference for testing. Each way of setting the

reference gives a different loss when testing the same cable plant.

Why 3 Ways?

The

reason for the existence of three methods is the

compatibility of test equipment to the cable plant;

whether the test equipment has connector interfaces that

allow direct connection to the cable under test.

The

options for use of these three methods are:

- If

the test equipment has connectors

compatible with the cable plant, a one-cable

method can be used. This is usually the preferred method.

- If

the test equipment does not have

connectors compatible with the cable

plant, a two- or three-cable method must

be used.

- If

the test equipment does not have

connectors compatible with the cable

plant and the connectors are the “plug and

jack” or “male, female” type, a

three-cable method must be used.

It all depends on the connectors on the cable plant you

are testing and the connector interfaces on your test

equipment.

Why use a 1-cable method?

The 1-cable method is used when the instruments have connectors that match the cable plant under test, e.g., both have SC connectors. The 1-cable method has always been the method of choice

because it does not require compensating for the

connections in the reference cables when setting the

"0dB" reference. It's like we discussed measuring

transmitter power above. You measure the output of the

launch reference cable, connect it to the cable plant

under test, launch power through that first connection

and measure the loss of all losses in the cable plant.

The meter connects to the cable plant at the far end

with a receive reference cable, and when the meter makes

it's measurement it includes the connection of the

receive reference cable. Thus both connections on each

end of the cable plant are measured, Just like the

actual link will work in operation. No corrections are

needed. (This method was originally called "Method B" in TIA standards.)

Why use a 2-cable method?

If you have a LC cable plant and your

instruments have SC connector interfaces? You

can use hybrid reference cables

with SC connections on one end for your

instruments and LCs on the other end to mate with the cable plant.

Use a LC mating adapter to set your 0 dB

reference -

including that connection - and make

measurements

remembering - or ignoring - that your reference

value

included one unknown connection. (This method was originally called "Method A" in TIA standards.)

Why use a 3-cable method?

If you are trying to test connectors that do not

match the connections on your instruments nor do they

mate with each other because they are gendered -

male/female or plug/jack? Hybrid reference cables won't

help here, so you go to a "cable substitution" test. Set

up your instruments with hybrid cables and set your

reference with a third cable that is a short version of

the cable plant you want to test. Since most cable

plants using plug/jack connectors (like a MPO prefab

cable plant or multipin military connectors) have the

permanently installed cable plant end in connectors of

the same gender (MPO jacks are connectors with pins),

you will have your instruments with similar cables and

the reference cable will have the opposite styles of

connectors to mate with them. (This method was originally called "Method C" in TIA standards.)

Just remember that you will make measurements that yield

different loss values depending on the reference method

you use.

All

three methods are approved in most standards and at

least the 1-cable or 3-cable methods are approved in all

standards we're aware of.

Generally

network standards prefer the 1 reference cable loss

method, but that requires that the test equipment uses the

same fiber optic connector types as the cables under test.

If the cable has different connectors than the test

equipment (e.g. LCs on the cable and SCs on the tester),

it may be necessary to use a 2 or 3 cable reference, which

will give a lower loss since connector loss is included in

the reference and will be subtracted from the total loss

measurement. Any of the three methods are acceptable, as

long as the method is documented. Be careful, however, as

most network link losses may assume a 1 cable reference,

which can affect the acceptance of the cable plant.

It is important to understand that the three reference

methods will give different loss readings because of the

connections included when setting the reference with 2 or

3 cables. Here is

an explanation of the differences in loss readings you

will see with each method.

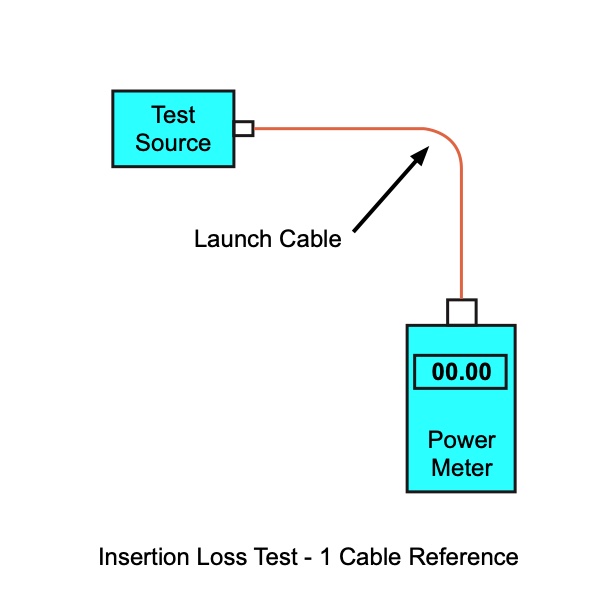

Insertion Loss, 1 Cable Reference

This method uses only one reference cable attached between

the test source and the power meter. The meter, which has

a large area detector that measures all the light coming

out of the fiber, effectively has no loss, and therefore

measures the total light coming out of the launch

reference cable. Once the reference is set, the launch

reference cable should not be removed from the source, as

it may have a different coupled power when reattached.

When the cable is tested as shown above, the

loss measured will include the loss of the reference cable

connection to the cable plant under test, the loss of the

fiber and all the connections and splices in the cable

plant and the loss of the connection to the reference

cable attached to the meter.

It is important to note with all these tests

the quality of the reference cables is important in the

uncertainty of the measurement. If one uses reference

cables with bad connectors, the losses when mated to the

cable under test will be higher than they should be, not a

good result if you want the installed cable to show the

quality of your installation processes! Installers should

test all reference cables using FOTP-171 single-ended

cable tests to ensure their quality. Cables with losses

higher than 0.5 dB per end should be cleaned and retested,

then discarded if they do not meet the 0.5 dB max loss.

Dirt is always another issue. If any of

the connectors are dirty, measurements will show higher

loss and more variability.

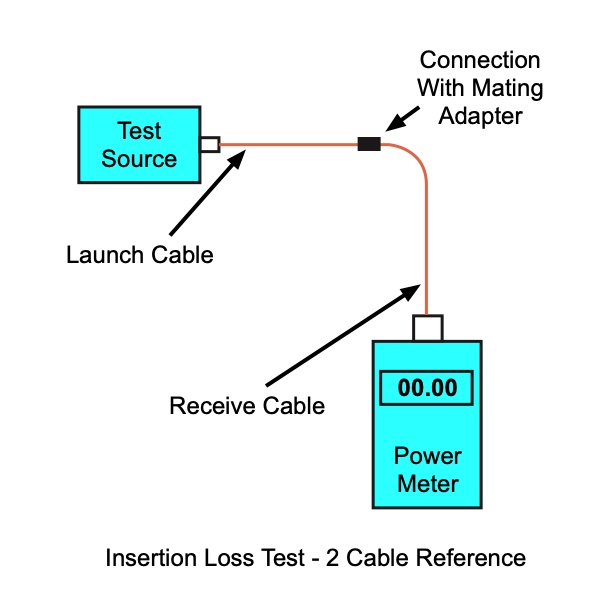

Insertion Loss, 2 Cable Reference

This method probably evolved from the telcos

where lengths were long and the instruments were brought

together only once a day for calibration, plus instruments

often had connectors different from the cable plant (e.g.

biconics on the cable plant and SMAs on the instruments.)

Here the launch reference cable is attached to the source,

the receive reference cable to the meter, then the two

cables are mated to set the reference. Once the reference

is set, the launch reference cable should not be removed

from the source, as it may have a different coupled power

when reattached, and one should probably do the same at

the meter.

Setting the reference this way includes one

connection loss (the mating of the two reference

cables)

in the reference value. When one separates the

reference

cables and attaches them to the cable under test,

the dB

loss measured will be less by the connection loss

included

in the reference setting step (compare the display

on this meter to the one above used with a 1 cable reference.) That's

approximate, by the

way, since the variations in mating alignment make

the

loss slightly different each time two connectors

are

mated.

Anyway, this method gives a loss that's

less than the 1 cable reference, Method B (above) and

because one connection is included in settting the

reference, it has a higher variability. Dirt is always an

issue. If any of the connectors are dirty, measurements

will show higher loss and more variability. If the

connectors are dirty when setting the reference but

cleaned afterwards before testing the cable, one gets a

lower loss, or sometimes even a gain!

Why would you use this method? If your

test equipment has different connectors than the

cable

under test, but the connectors are all mateable

with

proper mating adapters, this method can be used. A

standard example is test equipment with SC connectors and a cable plant

with LC connectors. The reference cables would be hybrids with SC

connectors on one end to mate with the equipment and LCs on the other

end to mate with the cable plant.

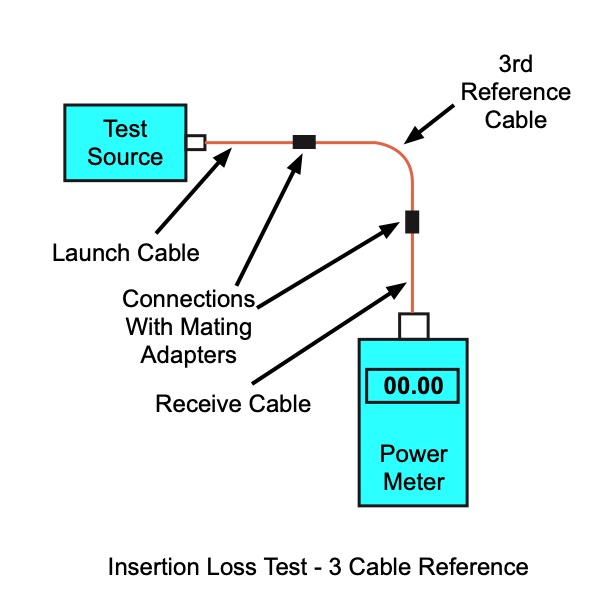

Insertion Loss, 3 Cable Reference

Some of the newer connectors are

male/female or plug/jack, not two males that use a mating

adapter to create a connection. One connector is used on

the jack in the wall or patch panel and one is used on a

patchcord. Examples are the MPO and mil-style 38999. These

connectors cannot be mated to test equipment nor can two

similar ( plug or jack ) be mated with a mating adapter.

Reference cables generally will be patchcords with

plugs while the cable under test will have jacks on either

end. The only way to get a valid reference is to use a

short cable of known good condition as a "stand-in" for

the cable to be tested (often called a "golden reference cable") to set the reference. To test a

cable, replace the reference cable with the cable to test

and make a relative measurement. That means this is sometimes referred to as a "cable substitution test."

Obviously this method includes two

connection losses in setting the reference, so the

measured loss will be less by the two connection losses

and have greater uncertainty (compare the display on this meter to the one above used with a 1 cable reference.) . Dirt is again an issue. If

any of the connectors are dirty, measurements will show

higher loss and more variability. If the connectors are

dirty when setting the reference but cleaned afterwards

before testing the cable, one gets a lower loss, or even a

gain!

Why would you use this method? If your

test equipment has different connectors than the

cable

under test and the connectors on the cable to test

are not

mateable, this method can be used. For example a

cable plant with MPO connectors has two types of connectors, those with

pins and those with holes, so when the cables mate, the pins go into the

holes on the other connector to align the connectors. The installed

cable plant has connectors with pins while patchcords have connectors

with holes. In setting the reference, the reference cables would have

connectors with holes while the 3rd reference cable would have

connectors with pins. When that cable is used for a reference then

removed, the reference cables can be mated with the ends of the

installed cable plant which has connectors with pins.

Since this method works

with any connector style, it has been chosen for several

international test standards.

Since there is some confusion about what each method

actually measures, the FOA has a web page that explains it

in simple diagrams and math. Read

Loss Math.

Summary: Which Reference Method Should

Be Used?

For insertion loss testing, it depends

on the types of connectors on your test equipment and the

connectors on the cables you need to test. If your cable

plant has the same connector styles as your test set, or

all the connectors use the same 2.5 mm ferrule style

common to ST, SC, FC and some other connectors, you can

use the one cable reference method.

If your test equipment has ST or SC

connectors and you must test LCs on the cable plant, you

may have no choice but to use a 2-cable reference or 3

cable reference. To compare these test results with

a 1 Cable Reference, you must add an estimated loss

for the connector included in the reference measurement,

say 0.3-0.5 dB for a typical connector on a high-quality

factory-made patchcord.

If your test equipment has ST or SC

connectors and you must test duplex male/female connectors

like the MT-RJ on the cable plant, you may have no choice

but to use a 3-cable reference. To compare these test

results with a 1 Cable Reference, you must add an

estimated loss for the connectors included in the

reference measurement, say two times 0.75 dB for a typical

MT-RJ connector on a high-quality factory-made patchcord.

More on testing cables

with different types of connectors.

Table 1. Reference methods for fiber optic insertion loss testing.

| Reference

Method (OFSTP-14) |

Reference

Cables |

Connectors

Included in Reference Measurement |

Estimated

reduction in measured loss |

Estimated

increase in errors |

| 1

Cable Reference | 1,

launch | 0 | 0

dB | 0

dB |

| 2 Cable

Reference |

2,

launch and receive |

1 |

0.2-0.75

dB |

+/-0.2

dB |

| 3 Cable

Reference |

3,

launch, receive and “golden cable” |

2 |

0.4-1.5

dB |

+/-0.25

dB |

Table 2. Recommended reference methods for connectors

| Connector

Type |

Mates

to test equipment |

Does

not mate to test equipment |

| Plug

to Plug with mating adapter |

1,

2 or 3 Cable Reference |

2 or 3 Cable Reference* |

| Plug

to Jack |

1

or 3 Cable Reference |

3

Cable Reference |

*The 2 Cable Reference can be used if the connector

under test can be adapted to the connector interface on

the test set – e.g. a tester with SC interface, but ST and

FC can be mated to SC with a hybrid mating adapter, so SC

reference cables can be used.

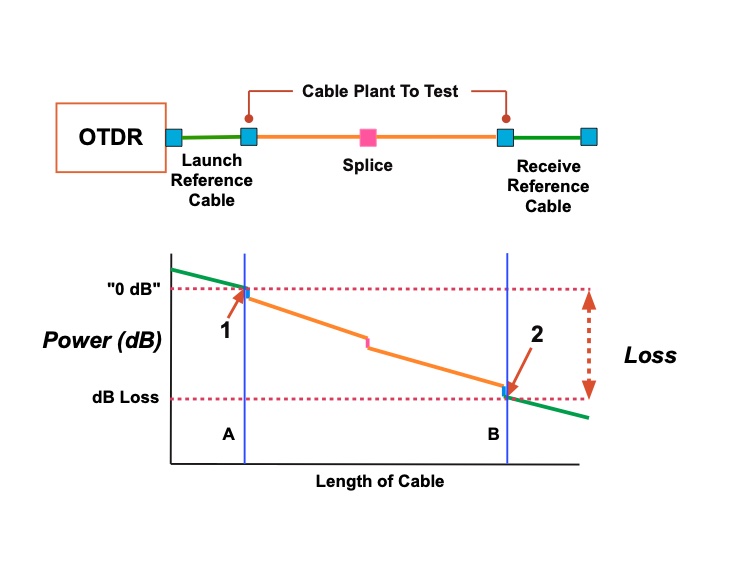

Reference Cables For OTDR Testing

OTDRs test from one end of the

cable using the backscatter signature of the fiber

to make

an indirect measurement of the fiber. OTDRs always

require

a launch cable longer than the OTDR "dead zone" to

allow the instrument to settle down after

reflections from the high powered test pulse

overloads the

instrument. OTDRs have traditionally been used

with long

distance networks where often only a launch cable

is used because the test is mainly to verify splices as they are made.

However, this method does not measure the loss of the connector on

the far end. Adding a cable at the far end allows

measuring the loss of the entire cable, but negates the

big advantage of the OTDR, that it makes measurements from

only one end of the cable, since a tech is required to

attach the receive cable to each fiber as it is being

tested. More

on OTDR testing.

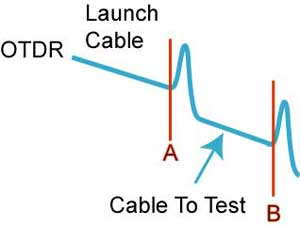

OTDR Test With Launch

Cable Only

When testing with an OTDR using only

the launch cable, the trace will show the launch cable,

the connection to the cable under test with a peak from

the reflectance from the connection, the fiber in the

cable under test and likely a reflection from the far end

if it is terminated or cleaved. Most terminations will

show reflectance that helps identify the ends of the

cable.

Using markers A (set at the end of the

launch cable) and B (set at the end of the cable under

test) , the OTDR can measure the length of the cable under

test and the loss of the connection to the cable under

test plus the loss of the fiber in the cable under test

and any other connections or splices in the cable under

test (not shown.)

This method does not, however, test the

connector on the far end of the cable under test because

it it not connected to another connector, and connection

to a reference connector is necessary to make a connection

loss measurement.

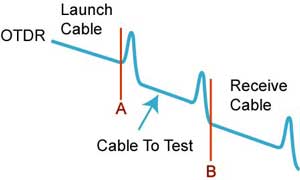

OTDR Test With Launch And

Receive Cable

If a receive cable is used on the far

end of the cable under test, the OTDR can measure the loss

of both connectors on the cable under test as well as the

fiber in the cable and any other connections or

splices in the cable under test (not shown.) The

placement of the B marker after the connection to the

receive cable means some of the fiber in the receive cable

will be included in the loss measured. Most OTDRs have a

"least squares" test method that can subtract out the

cable included in the measurement of a single connector,

but this will not work on a double ended cable loss test.

Different Results From

Different Reference And Test Methods

So just how much does the loss of a

cable plant change with the different methods? The table

below shows test results for a 520 meter simulated cable

plant with multimode fiber tested four ways

at 850 nm using several different sets of reference cables

to see the results. Unfortunately, we did not use a

receive cable to get data for the fifth method mentioned

above, but we did take data in both directions. Using 10

different sets of reference cables and making multiple

measurements allowed calculating an average of each

measurement, comparable to what several different test

crews might find, plus calculating the standard deviation,

a statistical indication of the repeatability of the

measurement.

-

| Test

Method |

Results,

Loss in dB, Standard Deviation |

| 1

Cable Reference |

2.96

dB, +/-0.02 dB |

| 2

Cable Reference |

2.66

dB, +/-0.20 dB |

| 3

Cable Reference |

2.48

dB, +/-0.24 dB |

| OTDR

Launch Cable Only |

1.91

dB / 2.05 dB (reverse directions) |

|

-

Note how the loss of our test cable plant reflects the

comments we made above. The one cable reference method has

higher loss than the other methods, but it also has much

less measurement uncertainty (standard deviation.) The 2

and 3 cable reference methods have less loss because we

have subtracted the connector loss(es) included when we

set the reference for 0 dB loss, and the uncertainty is

higher because of the greater variance when connected to

the reference cables. And the OTDR measurement is

significantly lower than the other three methods plus is

0.14 dB different according to which direction we are

testing in. Note that if we added to the OTDR loss the

average connector loss difference in the other tests,

about 0.25 dB, the loss would still only be about 2.1 -

2.2 dB, significantly less than any of the insertion loss

tests.

If you want to read more about what each insertion loss

method actually measures and why the uncertainty is

different for each method, the FOA has a web page that

explains it in simple diagrams and math. Read

Loss Math.

Interpreting Test Data

What is the loss of this cable plant?

Well all of these measurements are strictly according

to international standards, so you can take your choice!

However, it might cause a problem if you attach some

network electronics.

Most network power budget specifications have been

written around an insertion loss test that uses a one cable reference

method. If your

cable has been tested with any other method, the lower

loss you measure will give you a false measurement of

system margin. If you are dealing with new, fast networks

like Gigabit Ethernet or Fibre Channel which have much

smaller operating power margins, you could be in trouble.

The different loss obtained in OTDR

measurements comes from it’s completely different

methodology. OTDRs use backscattered light to imply the

measurement while insertion loss is measured directly by

transmission. Some claims for using mode

conditioners to make OTDR and insertion loss data

correlate has not proven reproducible in independent tests

conducted by the FOA (Read

the report here.) A single-ended OTDR measurement,

which most tech use, does not test the connector on the

far end. Recent standards mention and sometimes require a

receive cable for OTDR tests, which would have added

0.2-0.3 dB to the loss measured in the test detailed

above. But having to use a receive cable with an OTDR

negates its advantage of being able to be tested from one

end by a single technician.

Additional Reading

Testing cables with

different types of connectors.

Fiber Optic

Measurement Accuracy

Table of Contents: The FOA

Reference Guide To Fiber Optics

|