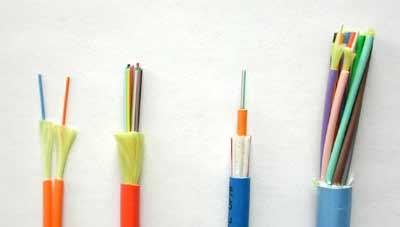

Fiber Optic Cable Construction  Cable Types: (L>R): Zipcord, Distribution, Loose Tube, Breakout Cable provides protection for the optical fiber or fibers within it appropriate for the environment in which it is installed. Fiber optic "cable" refers to the complete assembly of fibers, strength members and jacket. Fiber optic cables come in lots of different types, depending on the number of fibers and how and where it will be installed. It is important to choose cable carefully as the choice will affect how easy the cable is to install, splice or terminate and what it will cost. Cable's job is to protect the fibers from the environment encountered in an installation. Outdoors, it depends on whether the cable is buried directly, pulled in conduit, strung aerially or even placed underwater. Will the cable become wet or moist? Will it have to withstand high pulling tension for installation in conduit or continual tension in an aerial installation? Will the cable be exposed to chemicals or have to withstand a wide temperature range? What about being gnawed on by a squirrel, woodchuck or prairie dog? Indoors, cables don't have to be so strong to protect the fibers, but they have to meet all fire code provisions so the cable jacket has to be flame-retardant, Outside plant cable designs are optimized for the application type. In OSP installations, cables may be underground, direct buried, aerial or submarine (or simply underwater.) Underground Cables Underground cables are generally installed in conduit which is usually a 4 inch (10 cm) conduit with several innerducts for pulling cables. Here cables are designed for high pulling tension and lubricants are used to reduce friction on longer pulls. Automated pulling equipment that limits pulling tension protects the cables. Very long runs or those with more bends in the conduit may need intermediate pulls where cable is pulled, figure-8ed and then pulled to the next stage or intermediate pulling equipment is used. An alternative is to install duct lines and blow special lightweight cables into the ducts which can be faster and less stressful on the cable. Splices on underground cables are generally stored above ground in a pedestal or in a vault underground. Sufficient excess cable is needed to allow splicing in a controlled environment, usually a splicing trailer, and the storage of excess cable must be considered in the planning stage. Direct Buried Cable Direct buried cable is placed underground without conduit. Here the cable must be designed to withstand the rigors of being buried in dirt, so it is generally a more rugged cable, armored to prevent harm from rodent chewing or the pressures of dirt and rocks in which it is buried. Direct burial is generally limited to areas where the ground is mostly soil with few rocks down to the depth required so trenching or plowing in cable is easily accomplished. Splices on direct buried cables can be stored above ground in a pedestal or buried underground. Sufficient excess cable is needed to allow splicing in a controlled environment, usually a splicing trailer, and the storage of excess cable must be considered. Aerial Cable Aerial installations go from pole to pole, but the method of securing cables can vary depending on the situation. Some cables are lashed to messengers or other cables, such as CATV where light fiber cables are often lashed to the heavy coax already in place. Cables are available in a “8” configuration with an attached steel messenger that provides the strength to withstand tension on the cable. Some cables are made to directly be supported without a messenger, called all-dielectric self-supporting cables that use special hardware on poles to hold the cables. Optical ground wire is used by utilities for high voltage distribution lines. This cable is an electrical cable with fibers in the middle in a hermetically-sealed metal tube. It is installed just like standard electrical conductors. Splices on aerial cables can be supported on the cables or placed on poles or towers, Most splices are done on the ground, although it is sometimes done in a bucket or even on a tent supported on the pole or tower. Hardware is available for coiling and storing excess cable. Submarine/Underwater Cables Sometime OSP installations involve running cables across rivers or lakes where other routes are not possible. Special cables are available for this that are more rugged and sealed. Even underwater splice hardware is available. Landings on the shore need to be planned to prevent damage, generally by burying the cable close to shore and marking the landing. Transoceanic links are similar but much more complex, requiring special ships designed for cable laying. Since OSP applications often use significant lengths of cables, the cables can be made to order, allowing optimization for that particular installation. This usually allows saving costs but requires more knowledge on the part of the user and more time to negotiate with several cable manufacturers.

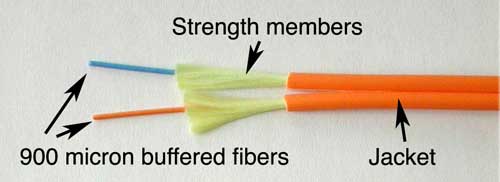

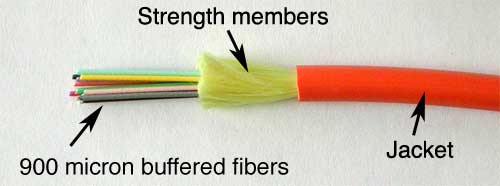

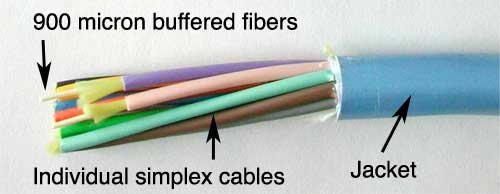

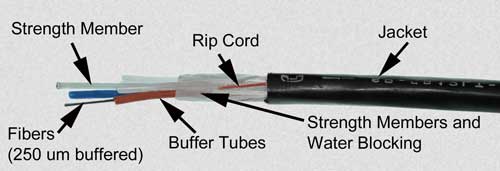

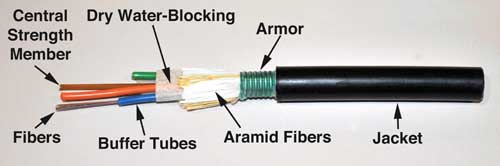

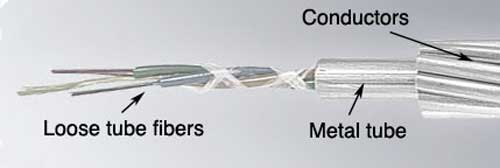

Loose Tubes (loose tube cables): Small, thin plastic tubes containing as many as a dozen 250 micron buffered fibers used to protect fibers in cables rated for outside plant use. They allow the fibers to be isolated from high pulling tension and can be filled with water-blocking materials to prevent moisture entry. Strength members: Strength members are usually aramid yarn, the same used in bulletproof vests, often called by the Dupont trade name Kevlar, which absorbs the tension needed to pull the cable and provides cushioning for the fibers. Aramid fibers are used not only because they are strong, but they do not stretch. If pulled hard, they will not stretch but eventually break when tension exceeds their limits. This ensures that the strength members will not stretch and then relax, binding the fibers in the cable. The proper method of pulling fiber optic cables is always to attach the pull rope, wire or tape to the strength members. Some cables also include a central fiberglass rod used for additional strength and to stiffen the cable to prevent kinking and damaging the fibers. When included, these rods should be attached to swivel pulling eyes for pulling and clamps in splice closures or patch panels when spliced or terminated. Few cables today use metallic strength members since it complicates installation by requiring the cable to be properly grounded and bonded. Cable Jacket: The outermost layer of protection for the fibers which is chosen to withstand the environment in which the cable is installed. Outdoor cables will generally be black polyethylene (PE) which resists moisture and sunlight exposure. Indoor cables use flame-retardant jackets that can be color-coded to identify the fibers inside the cable. Some outdoor cables may have double jackets with a tough layer of armor between them to protect from chewing by rodents or Kevlar for strength to allow pulling by the jackets. Indoor cables usually have a flame-retardant PVC (polyvinyl chloride) jacket for general or riser use and some other special plastic for plenum use in air handling areas. Indoor-outdoor cables usually have a PE outer jacket that can be removed to expose a flame-retardant inner jacket for use within buildings. Protection Against Water and Moisture Cables installed outdoors require protecting the fibers from water. Either a gel or as is becoming more common, absorbent tape or powder, is used to prevent water from entering the cable and causing harm to the fibers. Generally, this applies to loose tube or ribbon cables, but dry water-blocking is used on some tight buffer cables used in short outdoor runs, such as building to building on a campus or to an outdoor wireless antenna or CCTV camera. Protection Against Crushing or Rodent Penetration Some cables have armor, usually metallic but sometimes hard plastic, under the outer jacket resist crushing loads, such as cables installed under floors in data centers or in rocky soil, as well as to prevent rodent penetration. Metallic armor requires that the cable be properly grounded and bonded. Look at the pictures below to see how each type of cable incorporates these components.

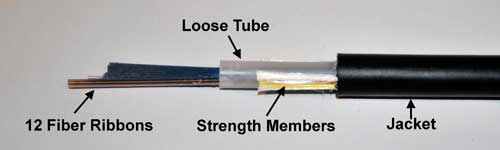

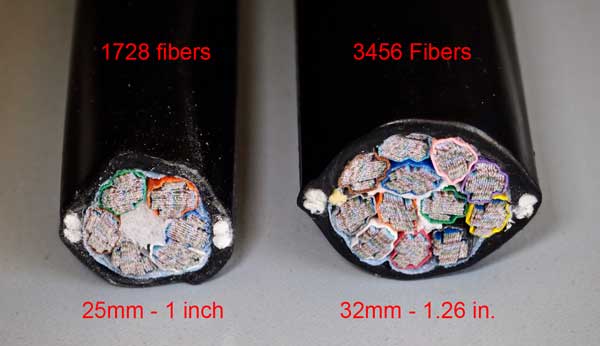

Simplex And Zipcord  These types are used mostly for patch cord and backplane applications, but zipcord can also be used for desktop connections. Simplex cables are one fiber, tight-buffered (coated with a 900 micron buffer over the primary buffer coating) with Kevlar (aramid fiber) strength members and jacketed for indoor use. The jacket is usually 3mm (1/8 in.) diameter, but some 2 mm cable is sometimes used with small form factor connectors. Zipcord is simply two of these joined with a thin web. Distribution Cables  Distribution cable is the most popular indoor cable, as it is small in size and light in weight. They contain several tight-buffered fibers bundled under the same jacket with Kevlar strength members and sometimes fiberglass rod reinforcement to stiffen the cable and prevent kinking. These cables are small in size, and used for short, dry conduit runs, riser and plenum applications. The fibers are double buffered and can be directly terminated, but because their fibers are not individually reinforced, these cables need to be broken out with a "breakout box" or terminated inside a patch panel or junction box to protect individual fibers. Breakout Cables  Breakout cable is a favorite where rugged cables are desirable or direct termination without junction boxes, patch panels or other hardware is needed. They are made of several simplex cables bundled together insdie a common jacket. This is a strong, rugged design, but is larger and more expensive than the distribution cables. It is suitable for conduit runs, riser and plenum applications. It's perfect for industrial applications where ruggedness is needed. Because each fiber is individually reinforced, this design allows for quick termination to connectors and does not require patch panels or boxes. Breakout cable can be more economic where fiber count isn't too large and distances too long, because is requires so much less labor to terminate. Loose Tube Cable  Loose tube cables are the most widely used cables for outside plant trunks because it offers the best protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes.These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member, surrounded by aramid strength members and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside plant trunking applications, as it can be made with the loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead or buried directly into the ground. Some outdoor cables may have double jackets with a metallic armor between them to protect from chewing by rodents or kevlar for strength to allow pulling by the jackets. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage. Loose tube cables with singlemode fibers are generally terminated by spicing pigtails onto the fibers and protecting them in a splice closure. Multimode loose tube cables can be terminated directly by installing a breakout kit, also called a furcation or fan-out kit, which sleeves each fiber for protection. Micro Cables

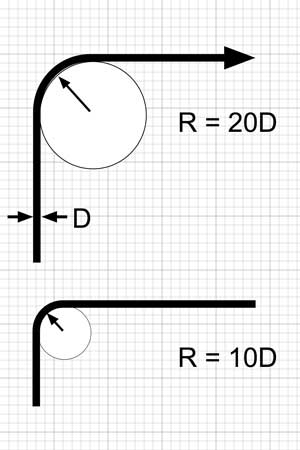

Microcable

is a term applied to a new class of cables that are very

high density cables. Two fiber developments make a

microcable feasible. Bend insensitive fiber allows fibers

to be packed into cables with much higher density since

the fibers are not as sensitive to the stress caused by

the crowded fibers. In addition, the bend insensitive

fibers can be coated with smaller diameter primary buffer

coatings, 200 microns or less compared to 250 microns for

conventional fibers, allowing more fibers to be packed

into a smaller space. The

differences between conventional and micro cables are

substantial. A 144 fiber loose tube cable is typically

15-16mm diameter while a comparable micro cable is only

about 8 mm diameter - half the size and about one-third

the weight. The smaller size allows for much larger fiber

counts, over 3,000 fibers in some designs. Microcables are available for both premises and outside plant installations. Their small size allows a different installation technique where the cable is "blown" into micro ducts, plastic tubes much smaller than conventional fiber innerducts or conduits. The cable is not really blown into the duct but floated on air to reduce friction then pushed into the duct. Ribbon Cable  Ribbon cable is preferred where high fiber counts and small diameter cables are needed. This cable has the most fibers in the smallest cable, since all the fibers are laid out in rows in ribbons, typically of 12 fibers, and the ribbons are laid on top of each other. Not only is this the smallest cable for the most number of fibers, it's usually the lowest cost. Typically 144 fibers in ribbons only has a cross section of about 1/4 inch or 6 mm and the jacket is only 13 mm or 1/2 inch diameter! Some cable designs use a "slotted core" with up to 6 of these 144 fiber ribbon assemblies for 864 fibers in one cable! Since it's outside plant cable, it's gel-filled for water blocking or dry water-blocked. Another advantage of ribbon cable is Mass Fusion Splicers can join a ribbon (12 fibers) at once, making installation fast and easy. Ribbon pigtails are spliced onto the cable for quick termination. Premises cabling also uses some ribbon cables, often in preterminated cabling systems where 12 fibers are terminated in one MTP connector. These cables are common in LAN backbones and data centers. Some manufacturers have introduced "flexible ribbons" that are not solid 12 fiber ribbons but are 12 fibers joined with periodic connections to the fibers next to it. These ribbons are more flexible and allow ribbon cables of new construction types, including rolled up ribbons in loose tubes instead of hard ribbons that have to be stacked up and can bend in only one direction. High Fiber Count Cables  This 1728 fiber cable is under 25mm or 1" diameter. It uses 200 micron buffer fibers Below are two cables with 1728 and 3456 fibers.  These high fiber count cables are very high density and often use regular or flexible ribbons since ribbon splicing is necessary to splice these cables in any reasonable time. They are usually made with smaller diameter buffer coatings, 200 instead of 250 microns, and bend-insensitive fibers that allow more densely packing fibers into smaller diameter like microcables above, but with very large numbers of fibers, 1728, 3456 or 6912 fiber cables now being available. They are primarily used for short runs in data centers or metropolitan areas. More on high fiber count cables. Armored Cable  Armored cable is used in direct buried outside plant applications where a rugged cable is needed and/or for rodent resistance. Armored cable withstands crush loads well, for example in rocky soil, often necessary for direct burial applications. Cable installed by direct burial in areas where rodents are a problem usually have metal armoring between two jackets to prevent rodent penetration. Another application for armored cable is in data centers, where cables are installed under the floor and one worries about the fiber cable being crushed. Indoor armored cables may have nonmetallic armor. Metallic armored cable is conductive, so it must be grounded properly. As with other fiber optic components, there are different names or meanings used. “Armor” in some companies’ jargon denotes a twisted heavy wire rope type cable surrounding the entire poly cable sheath/jacket. Single or double armor (two opposite ply layers of the steel wire) is typically used underwater near shore and shoals. Inner metallic sheath members of aluminum and/or copper are used for strength and for buried cable locating with a tone set. Aerial Cables Aerial cables are for outside installation on poles where consideration must be given to continual tension from the cable weight as well as wind and ice loads. Regular outdoor loose tube cables can be helically lashed to a messenger or another cable (common in CATV.) Some cables have heavier jackets and stronger metal or aramid strength members to make them self supporting (called all-dielectric self-supporting or ADSS cable if the strength members are nonconductive.) Self-supporting cables use special hardware to handle the installed tension on the cables caused by the weight of the cables and environmental factors like wind. Aerial hardware to store slack cable can be mounted on the cable itself or on utility poles.  The cable known as a figure 8 cable has a cable bonded to an insulated steel or all dielectric messenger for support. The messenger is supported at each pole. If the messenger is steel, it must be grounded properly. You can also get figure 8 conduit which can be installed then cable pulled into the aerial conduit.  All dielectric, self-supporting cable (ADSS) uses special hardware on the poles and at the ends to distribute the tension on the cable to prevent damage.  A widely used aerial cable is optical power ground wire (OPGW) which is a high voltage distribution cable with fiber in the center. The fiber is not affected by the electrical fields and the utility installing it gets fibers for grid management and communications. This cable is usually installed on the top of high voltage towers but brought to ground level for splicing or termination. Underwater And Submarine Cables  It is often necessary to install fibers under water, such as crossing a river or lake where a bridge other above water location is not possible. For simple applications a rugged direct burial cable may be adequate. For true undersea applications, cables are extremely rugged, with fibers in the middle of the cable inside stainless steel tubes and the outside coated with many layers of steel strength members and conductors for powering repeaters. Submarine cables are completed on shore, then loaded on ships and laid from the ship, often while operational to ensure proper operation. Even More Types Are Available There's double-jacketed indoor/outdoor, dry water-blocked, etc. Every manufacturer has it's own specialties and sometimes their own names for common cable types, so it's a good idea to get literature from as many cable makers as possible. And check out the smaller cable companies; often they can save you a bundle by making special cable just for you, even in relative small quantities. Air-Blown Fiber  Another "cable" type is not really cable at all. By installing a "cable" which is just a bundle of empty plastic tubes, you can "blow" fibers into the tubes using compressed gas as needed. If you need to upgrade, blow out the old fibers and blow in new ones. Both indoor and outdoor versions of air-blown fiber cables are available and its even been used for FTTH. Special fibers are required that have been coated for easier blowing through the tubes, but any singlemode or multimode fiber is available. It's more expensive to install since the tubes must be installed, special equipment and trained installers are needed but can be cost effective for upgrades. Hybrid and Composite Cables In standards, the distinction between hybrid and composite cables has flipped several times in the history of fiber optics and differed among standards bodies. A hybrid cable originally meant a cable with two types of fibers, usually MM and SM, or a hybrid patchcord with, for example, a SC connector on one end and LC on the other end. In the beginning a composite cable was defined per the US National Electrical Code: NEC Article 500.8(F) “Optical fiber cable contains conductors that are capable of carrying current (composite optical fiber cable)" More recent standards like the ones from IECA (Insulated Cable Engineers Association) use the term hybrid for cables with fiber and conductors. Two examples: Hybrid Cables and FTTA cables Cable Design Criteria Choosing a cable requires consideration of all the environmental factors involved during installation and during the cable's lifetime. Here are some of the most important factors. Pulling Strength Some cable is simply laid into cable trays or ditches, so pull strength is not too important. But other cable may be pulled thorough 2-5 km or more of conduit. Even with lots of cable lubricant, pulling tension can be high. Most cables get their strength from an aramid fiber (Kevlar is the duPont trade name), a unique polymer thread that is very strong but does not stretch - so pulling on it will not stress the other components in the cable. The simplest simplex cable has a pull strength of 100-200 pounds, while outside plant cable may have a specification of over 800 pounds. Bending Limits (Bend Radius): The normal recommendation for fiber optic cable bend radius is the minimum bend radius under tension during pulling is 20 times the diameter of the cable. When not under tension, the minimum recommended long term bend radius is 10 times the cable diameter.  Under tension (top) and after pulling (bottom) Bend radius example: A cable 13mm (0.5") diameter would have a minimum bend radius under tension of 20 X 13mm = 260mm (20 x 0.5" = 10") That means if you are pulling this cable over a pulley, that pulley should have a minimum radius of 260mm/10" or a diameter of 520mm/20" - don't get radius and diameter mixed up! Water Protection Outdoors, every cable must be protected from water or moisture. Protection starts on the outside with a moisture resistant jacket, usually PE (polyethylene), and a filling of water-blocking material. The usual way has been to flood the cable with a water-blocking gel. It's effective but messy - requiring a gel remover (use the commercial stuff - it's best- -but bottled lemon juice works in a pinch!). A newer alternative is dry water blocking using a water–absorbent tape or powder – similar to the material developed to absorb moisture in disposable diapers. Most cable manufacturers now offer dry water-blocked cables. Crush Loads or Rodent Penetration: Armored cables are used because their strong jackets withstand crushing and rodent penetration. Direct burial OSP cables are usually armored or installed in conduit. Armored indoor cables are available with NEC rated jackets for placement with other cables under false floors, as in data centers. Fire Code Ratings For Premises Cables Every cable installed indoors must meet fire codes. OSP cables can only be run 50 feet (about 15 meters) inside a building without conduit or connecting to a rated premises cable. That means the jacket must be rated for fire resistance, with ratings for general use, riser (a vertical cable feeds flames more than horizontal) and plenum (for installation in air-handling areas. Most indoor cables use PVC (polyvinyl chloride) jacketing for fire retardance. In the United States, all premises cables must carry identification and flammability ratings per the NEC (National Electrical Code) paragraph 770. In Canada, it’s CEC and other countries have similar cable ratings. These ratings are:

Grounding and Bonding Any cable that includes any conductive metal must be properly grounded and bonded per the NEC for safety. Indoor cables rated OFC, OFCG, OFCR or OFCP and outdoor cables with metallic strength members or armor must be grounded and bonded. All composite cables must be properly grounded and bonded also. Cable Color Codes Outdoor cables are generally black but premises cables are color-coded. De facto standard color codes for cable jackets have been yellow jackets for singlemode and orange jackets for multimode. With two multimode fibers now in common use, 62.5/125 and 50/125, and four versions of 50/125 fiber, a more comprehensive industry standard for color codes was required. It's important to follow the TIA-598 standard to prevent mixing up cables. Fiber Color Codes Inside the cable or inside each tube in a loose tube cable, individual fibers will be color coded for identification. Fibers generally follow the convention created for telephone wires except fibers are identified individually, not in pairs. Since most loose tube cables have 12 fibers per tube, colors are specified for fibers 1-12, then tubes are color coded in the same manner, up to 144 fiber cables. In ribbon cables, each ribbon is color coded in this format then ribbons are stacked. For splicing long cable runs from similar cables (called concatenation), like color fibers are spliced to ensure continuity of color codes throughout a cable run.

Choosing Cables Choosing a fiber optic cable for any given application requires considering installation and environmental requirements plus long-term fiber requirements to cover expansion to newer communications networks. Installation requirements include where and how the cable will be installed, such as pulled in conduit outdoors or placed in cable trays in a building. Long term requirements need to consider moisture or water exposure, expected temperature range, tension (aerial cables), or other environmental factors. You should contact several cable manufacturers and give them detailed specifications for the installation. They will want to know where the cable is going to be installed, how many fibers you need and what kind of fibers (singlemode, multimode or both in what we call "hybrid" cables.) You can also have a "composite" cable that includes copper conductors for signals or power. The cable companies will evaluate your requirements and make suggestions. Then you can get competitive bids. Since the plan will call for a certain number of fibers, consider adding spare fibers to the cable - fibers are cheap compared to the cost of installing additional cables. Then you won't be in trouble if you break a fiber or two when splicing, breaking-out or terminating fibers. And consider future expansion needs. Most users install many more fibers than needed, especially adding singlemode fiber to multimode fiber cables for campus or premises backbone applications. Additional information on choosing cables is included in the chapter on fiber optic network design. More information on cables General Guidelines For Installing Fiber Optic Cable Here are some general guidelines for installing fiber optic cables that should be read by everyone before installing any cable. More information on installation. Videos on cable design, pulling and preparation on the FOA Channel on  Test Your Comprehension Table of Contents: The FOA Reference Guide To Fiber Optics |

|

|