Got

questions? Try the FOA

Guide and use the site search.

If you

don't find it there, email FOA.

Updated 11/21

Topics

(Click on them to jump to that section)

Technology

Manufacturing

Guide?

Q: Is there a guide published by FOA that provides

insight as to the process of fiber optic manufacturing? It's

my understanding that the guide stresses quality and controls

to ensure performance and reduce product loss?

A: We do have a guide

for manufacturers. It is mostly aimed at communications

systems and components manufacture. Here

is a link to download it.

Reflectance

Q: What is the importance of reflectance and all the other numbers in installing and trouble shooting a fiber circuit?

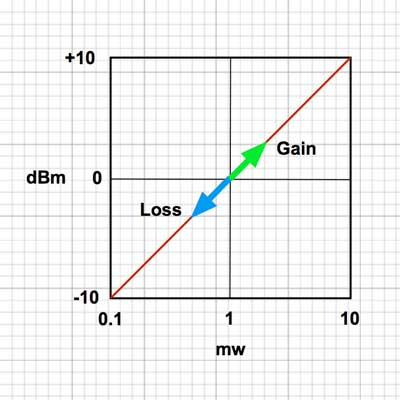

A: Reflectance has always been a secondary issue to connection

loss but has some important issues that need consideration. There are

two basic issues with reflectance, affecting with the output of laser

transmitters and creating background “noise” in a fiber link.

Reflectance can interact with the laser chip itself, causing laser

transmitters nonlinearities or random fluctuations in the output. The

background noise is a secondary issue, but can be seen in ghosts in an

OTDR trace. The light bouncing back and forth in the fiber that causes

ghosts will be added to the signal at the receiver end, adding noise to

the actual signal. Both these effects are more significant on shorter

links, for example FTTH or LANs using PONs (passive optical networks).

We always recommend using APC (angled physical contact) connectors on

short SM links. And most short SM networks do use APC connectors.

FOA tries to stick to the definition that reflectance is the light

reflected from a connection but some others call it “return loss.”

Return loss has been defined generally as the combination of reflectance

and backscatter from the fiber, and that’s how OTDRs measure return

loss. Standards vary in the definition sometimes.

Here is a FOA Guide page on reflectance that gives the basics and

explains how it is tested.

https://foa.org/tech/ref/testing/test/reflectance.html

Electromagnetic Interference

Q: Is there and electromagnetic interference with optic cables?

A: The fiber is glass and the cable is plastic, neither of

which are affected by electromagnetic interference. There is a cable

used in electrical transmission lines called OPGW- optical power ground

wire - that has fiber inside a wire conducting high voltage - doesn’t

bother the fiber at all.

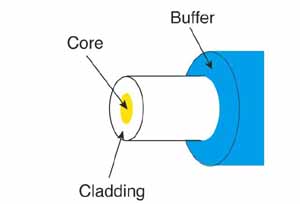

How Light travels In An Optical Fiber

Q: Is there a generalised ratio between

the length of an optic fibre and the length of the path actually taken

by a light pulse inside that fibre? If yes, do OTDRs factor in such

differences in any way? or they such sown the length of the actual path

of the light pulses?

A: Each optical fiber has an effective

independent of refraction. The index of refraction is the ratio of the

speed of light to the speed of light in the material: n=c/v where

n=index of refraction, c=speed of light in a vacuum and v=speed of light

in the fiber.

For an optical fiber, the manufacturer measures the index of refraction

which is usually in the range of 1.47. Corning SMF-28 singlemdoe fiber

for example is specified at 1.4670 @ 1310 nm and 1.4677 @ 1550 nm.

So if you use the equation above, the speed of light in SMF-28 fiber for

a 1310nm pulse is c/n or 300,000 km/s divided by 1.4670 = 204,500 km/s.

When an OTDR measures length, it actually measures the time its test

pulse takes to go to the end of the fiber and return, so the distance is

2X the actual fiber length. The distance is speed x time.

If a fiber is 1 km long and the speed is 204,500 km/s, the time

forlight to travel the 1km is 1/204500 = 0.00000489 seconds or about 5

milliseconds.

OTDR will measure that fiber as 10 ms becasue its pulse has to go both

ways, and it would calculate the length as i km, using that effective

index of refraction of 1.4670.

Back to your original question, the index of refraction is the generalized number based on how light travels in the fiber.

Applications

Managing And Maintaining a Fiber Optic Cable Plant During Its Lifetime.

Q: Are there guides / recommendations for optic fibre cable

life cycle management? (outside plant) including rehabilitation /

replacement timelines together with factors that may alter those

timelines ( such as seismic activity, extreme weather, human

activity-induced fibre cuts etc) also including typical performance

deterioration over the life cycle, and the performance levels at which

replacement / rehabilitation happens. Or does it happen (and is it

normally expected) that operators replace entire sections of fibre (say

400 km) as part of routine maintenance?

A: There is a saying here in the US that in fiber optics “the most common cause of failure is “backhoe fade” in underground cables

and “target practice” for aerial cables.” In other words, damage

caused by humans. We know of many fiber optic cable plants that have

survived natural disasters like earthquakes - in fact there is a lot of

work today using regular cables used in communications to monitor for

seismic activity. Fire can be a problem in remote areas, but often it’s

because the poles are burned causing the cables to fall.

Over the years we have questioned cable manufacturers about the lifetime

of fiber optic cable. They don’t like to make definitive statements but

we have been told that based on the cables installed in the past that

40 years is a probable lifetime for most cables. There are certainly

cables in use today that are over 30 years old already. The glass fiber

is not a problem, it’s the protection from the cables that will

eventually fail. Installation techniques can have an effect on the

longevity. For example splice closures should be sealed properly to

prevent ingress of moisture or dirt. Cables should not be installed with

bends below the rated bend radius or with excess tension.

FOA has always told users that fiber optic cables do not need maintenance (https://foa.org/tech/ref/user/maintain.html),

a response to some people advocating periodic inspection and cleaning

of connections, for example. That’s just more likely to cause damage.

When an accidental break in a cable occurs, we have guidelines for restoration (https://foa.org/tech/ref/restoration/rest.html), and planning for restoration when building the cable plant is very important.

Someday you will certainly want to replace cables, often well before the

lifetime of the cable, but generally because you need more fiber or the

older fiber will not support the network speeds you want for upgrades.

Planning for more fiber by installing more cables can be eased by

installing spare underground ducts when first installing cables - here

in the US, we call this “Dig Once” (https://foa.org/tech/ref/OSP_Construction/Underground_Construction.html). Testing fibers for higher speeds is called "fiber Characterization” (https://foa.org/tech/ref/testing/test/CD_PMD.html) and is routinely done when speeds above 10G or certainly 100G are considered for older fibers.

Knowing that the lifetime of fiber optic cable plants are ~40

years, it makes sense to plan ahead for future applications, installing

lots of fibers, leaving lots of open duct space and choosing network

architectures that will not obstruct upgrades. See the article on

Netly's network above.

Transmitting Multiple Data Types

Q: How do you integrate fiber optic digital communications with other sensing and control systems and platforms?

A: Fiber optic networks generally have lots of bandwidth and

sensors and control systems generally do not require much bandwidth. The

mixing of data streams is generally done by multiplexing the data using

electronics on each end, but one can also do it with wavelength

division multiplexing.

Single Fiber DWDM

Q: Can you do bidirectional links on a single fiber with DWDM? (Dense Wavelength Division Multiplexing)?

A: A company Called Edge Optical Solutions sells

multiplexers for bi-directional DWDM on one fiber by using

adjacent wavelength channels for each direction. It is good to ~400km

with coherent transceivers but cannot use fiber amplifiers for

repeaters.

Identifying Users On A PON Network

Q: How or what testing tool or technique can I

use to verify whether there is a live customer w/ONT

working on any fiber i may select @ a splice

enclosure prior to getting further down the cable

and to the MST service terminal. All our

fibers have light on them leaving the CO so when we

go into a splice enclosure to pick a fiber to

connect a drop to, to service a home, they are

usually all lit up in that enclosure.

A: The simple answer for a tool or technique

that can tell you if a customer is connected on an

output of a PON splitter is “documentation.” If you

know where each fiber is connected going downstream.

Then the IT person who programs users into the

system can tell you if that fiber is connected to a

customer. There is a possibility that there is a

test solution. Have you ever heard of a “fiber

identifier”? It’s a gadget that can tell if there is

signal in a fiber and some can identify the

direction it comes from. What I don’t know if the

unit can somehow indicate bi-directional traffic.

Nobody we contacted seems to know either.

Slow

Internet After Conversion From DSL To FIber

Q: Could

you please help me understand why I am getting a slow connection

(the same as when I was using anADSL box and sometimes even a

bit slower) while having a fiber optic connection to my home

(FTTH then RJ45 between wall & iMac)?

I am using an old iMac from early 2009 but the cable needed is a

regular RJ45, so I do not see why it should not take the high

speed connection...

As a matter of fact, it still takes several seconds (3 to 6 or

even 12) for some pages to load...

A:There

are several possible reasons your Internet is slow loading

pages.

The fiber optic link to your residence may have little or

nothing to do with the speed you see. If you use a speed test to

check the speed of the connection, it’s probably going to show

faster speeds, but it generally only tests the connection to

your ISP - Internet Service Provider - not to the Internet or a

remote data center. The actual connection to the data

center sending you the pages you request may be hundreds or

thousands of km long and through many switches, so that could

affect the speeds.

The major problem we see is the speed of the connection of your

ISP to the Internet. If they have many subscribers, the “traffic

jam” is at their connection. This is generally easy to see over

the time of day. In the evening when many people are streaming

TV or movies, it sends to get much slower, just like automobile

traffic during rush hour. At times when fewer people are online,

speeds will be faster.

We have exactly the same problem here in Santa Monica. Our

Internet over a cable modem tests at 100-200 Mb/s but pages are

slow loading because so many people are on the network at once.

However, I also suspect your 12 year old iMac. The typical web

page is more complex than a decade ago and may contain hundreds

of files including graphics that have to be downloaded and

assembled for you to see the page.Newer computers are much

faster and software is more efficient at handling large pages.

Campus Network Expansion

Q: Any advice for expanding a campus fiber optic network?

A: Here are some thoughts:

- Building

to building can more easily be done with indoor/outdoor

cable to get past the 50’ code limit for OSP cable.

- Many

campuses have ducts but they are often crowded. Microducts

or fabric ducts are often the solution even if you have to

pull out an older cable to pull in new microducts into one

old duct.

- Microducts

and blowing microcables are gaining lots of traction for

their practicality.

- Microducts

and microtrenching can be what we call “construction without

disruption.”

- We

are seeing more and more directional boring - works fine as

long as you know where other buried utilities are! Many

contractors need to learn more about underground location.

- People

are finally getting the idea about singlemode fiber - now

it’s probably cheaper than multimode.

- Passive

optical LANs can save money. Biggest advantage is the

upgrade from GPON to 10GPON is seamless - you can even run

both simultaneously, e.g. for a student system and a

faculty/research system.

- High

fiber count cables are tempting, but require special

handling and lots of manhole/handhole space.

- We’re

working with a Corning “Pioneer” (retired engineer) on

trying to educate installers about bend radius violations,

esp when pulling large fiber count cables.

- Most

installations shortchange manhole/handhole space.

- Aerial

is sometimes used. Lashing to a messenger is probably best.

We worked with a school in Canada last year trying to use

short lengths of ADSS and it was not cost effective nor was

their much applications support for short ADSS links.

- Line

of sight wireless (RF or optical) works across highways and

may be cheaper than construction for fiber.

Minimum

Link Length

Q: I have a question regarding minimum fiber optic

distances for horizontal runs. Is there a minimum distance for

a horizontal fiber optic run? Any information regarding this

would be greatly appreciated. Thank you for you help!

A: The answer to your question is for the most part no,

there is no minimum distance for a fiber optic link. For

example, fiber is used in offices, data centers, etc.

sometimes connecting equipment on a single rack. And there are

many fiber optic links used on platforms - aircraft,

helicopters, ships, etc. - and in command posts.

Most of the Ethernet standards are based on a 2m minimum, but

also most are defined by a maximum length. For multimode

systems, the max length is mainly a bandwidth issue, so

shorter links are no problem.

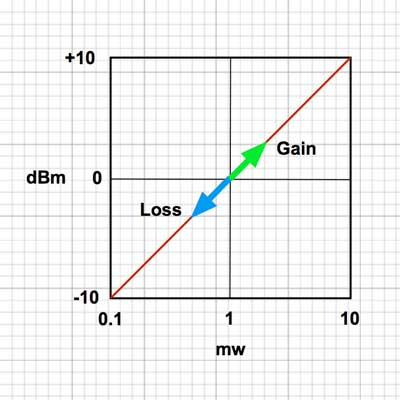

For singlemode links, the bandwidth is not an issue, it’s the

power budget, limited by the transmitter power and receiver

sensitivity, translated into the loss of the cable plant. But

for receivers, often they have not only a minimum input power

limited by their baseline noise but also a maximum power they

can have before saturating and causing high bit error rates.

See “Power

Budget” on this page in the FOA Guide. So if a

singlemode link is short, the receiver can be overloaded so an

attenuator is used at the receiver.

There is a secondary problem with singlemode systems,

reflectance. Reflections from connections can cause problems

with both transmitters and receivers, a topic covered in the

link given above. The reflectance problem can be solved with

APC connectors.

The FOA

Guide has many pages on links, networks, reflectance,

testing, etc. that you may find helpful.

What

Is A Ring Network?

Q: If according to the TIA or ISO structured cabling

standards the fiber optic campus backbone must be

star-hierarchical type, how should a fiber optic "ring" be

built? to always ensure connectivity on a LAN?

A: A “ring” network consists of a series of links

connecting equipment (nodes) in series until the last one

connects back to the first. Since the links are communicate in

both directions, the network can still operate if any one

cabling link or equipment fails. Today, survivability is

usually ensured by using a “mesh” network; the architecture of

data centers, the Internet or phones. In addition to having a

series connection of nodes, there are other interconnections

that provide for multiple alternative paths. See Networks

in the FOA Guide.

Crossed

Connections

Q: If a FO connector is crossed connected i.e Rx

connected Rx and Tx to Tx at both end, will it works?

I know in theory it will not due to light circuits

arrangement, but is there SFP in the market can tolerate

that?

A: We do not know how a SFP could sense and change

polarity unless it had an optical switch inside the module. A

transmitter is a laser or LED and a receiver has a

photodetector. Unless one could have the devices change

function, changing polarity would be impossible.

FTTH

GPON

Q: Can you guide me some websites or pages where I can learn more about GPON Technology please?

A: FOA Guide has a big section on FTTH and OLANs using GPON technology. Follow those links, Also FOA has a new book, The FOA FTTH Handbook you can order from Amazon.

Cheating

On Link Length

Q: I have a fiber run for a camera starts at location A

to location B it is 467 feet. Location B jumpers through

to location C which is 2060 ft at location C. Transceivers

areSFPs ONLY GOOD UP TO 1800 ft, but this company only has a

multimode system. Is there something i can do to make this

work?

A: It might work as is, since electronics are usually

quoted with conservative specs and will work farther than

specified most of the time. If you have several SFPs, test the

output power to see if it exceeds specs and choose the 2 ones

with highest power. If that still doesn’t work, contact SFP

manufacturers for higher power units.

Errors

In A Data Link

Q: What is the significance of bit error, and what is

the acceptable rate for communications and submersible

vehicles?

A: On any data link, there is an acceptable amount of

error that can be tolerated. If it’s a digital voice link, a

BER 10E-6 (1 error in 1million bits) is acceptable without

affecting voice quality. If it’s a link to your bank, the

typical standard is a million times higher (10E-12). Link

protocols usually have ways to determine BER, like attaching a

checksum to the end of a data packet and having it checked at

the receiving end. If a error is suspected, the packet will be

discarded and retransmitted. Here is a tutorial

on BER and an explanation

of errors in a a fiber optic link.

GPON

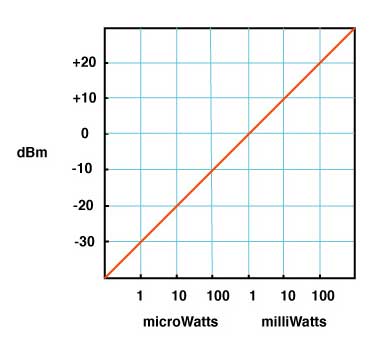

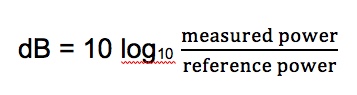

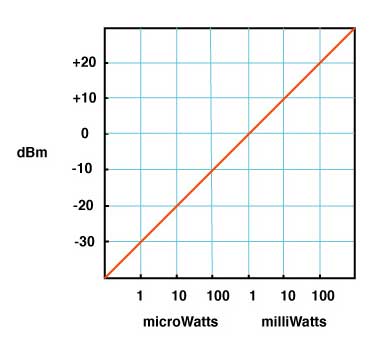

Q What is normal Range for good power in an FTTH fiber?

A: The GPON specification for downstream power from the

OLT is OLT transmitter power should be 0 to +6dBm and link

attenuation in the range of 13 to 28dB, which says receiver

power the ONT must be a maximum of 13 dB less than +6dBm or

-7dBm and a minimum of 28 dB less than 0dBm or -28dBm, so -7

to -28dBm at the receiver.

Upstream, the similar calculation is ONT transmitter -4 to

+2dBm and the receive power at theOLT is -11 to

-32dBm.

See http://thefoa.org/tech/ref/appln/FTTH-PON.html for the

full specifications for GPON.

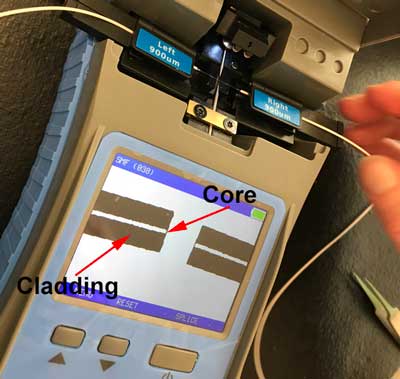

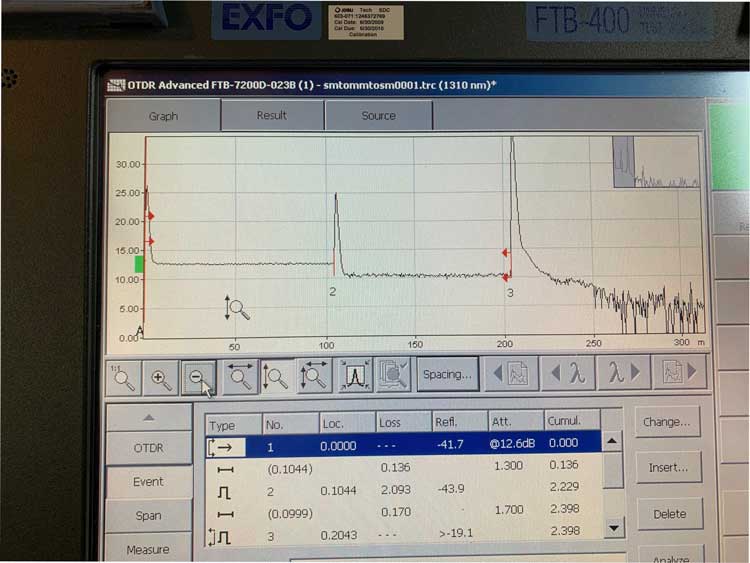

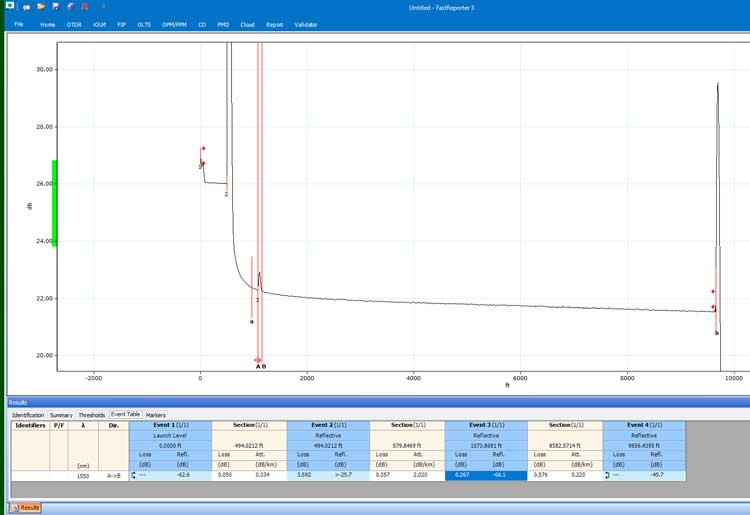

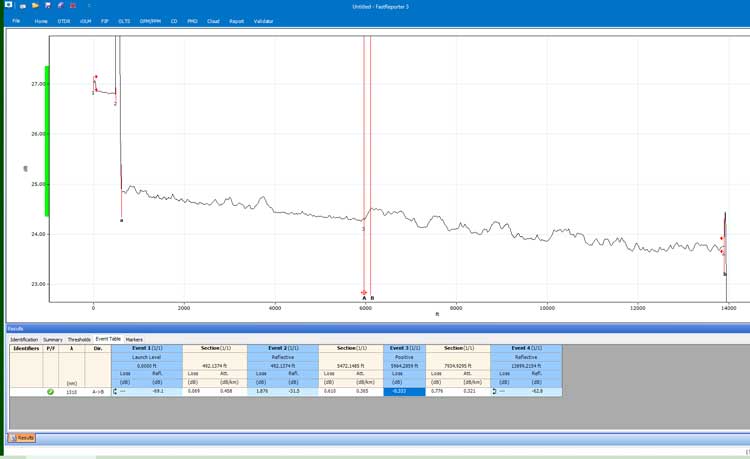

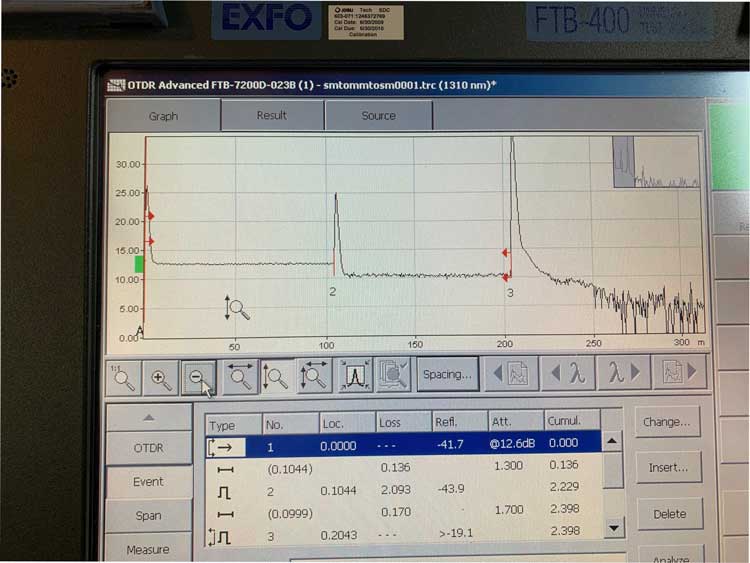

Reflective

Events Causing Transmission Problems

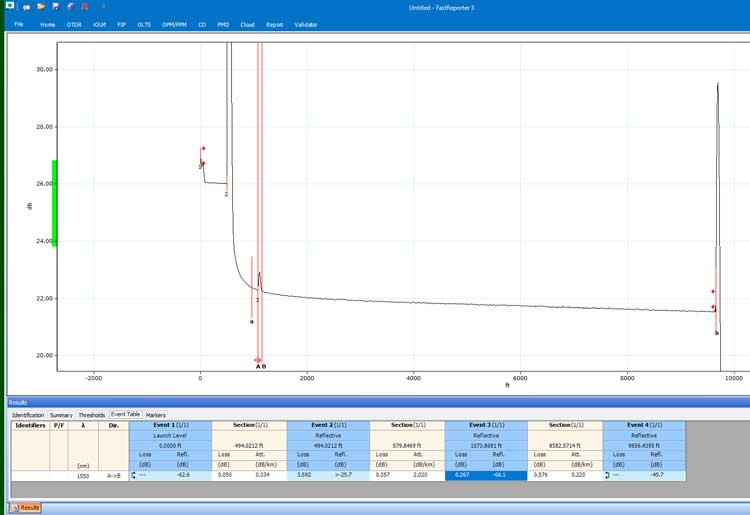

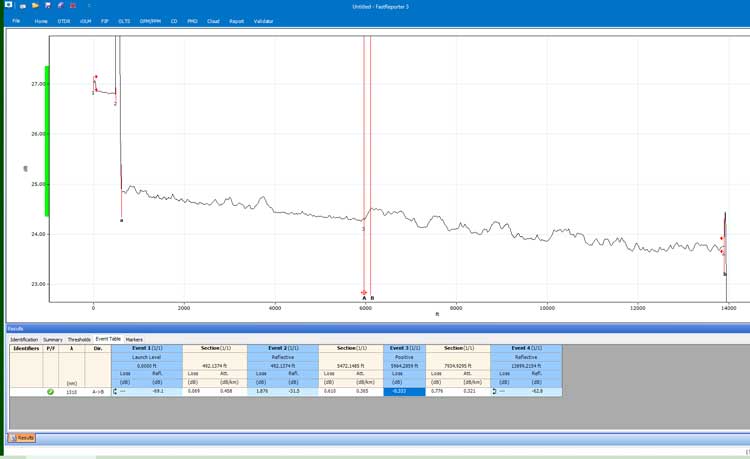

Q: I have a technical question about reflective events.

I recently assisted to troubleshoot an intermittent SM fiber

link for a customer. The cable was dug up a few years ago and

a fiber contractor has (fusion spiced) a different chunk of

cable into the link to repair it. When troubleshooting the

link, I checked the cable with the otdr. I found that each of

the 12 fibers had a reflective event at the fusion splice.

This was only at the splice tube closest to me. The other

fusion splices in the other tube were virtually invisible (as

they should be). I'm a little puzzled as to why there are

reflections at the fusion splices. I did a little research,

but couldn't come up with a good answer as to what is a

possible cause of the reflections. (The OTDR also showed a lot

of ghosting on every fiber tested) (in some cases it recorded

over 40 ghost events) Although I haven't been able to confirm

that there is high Bit error rate due to the transceiver not

providing these statistics, (except for 3 out of 10 pings

fail) I am suspecting that High reflectance is possibly the

cause of their unreliable fiber link.

A: Reflectance is a big problem in SM links,

especially short links. If you are seeing lots of ghosts, I

suspect the link is very short. Fusion splices can have

reflectance if the splicer is improperly set and the fusion is

incomplete or has bubbles. Those splices should have not only

have reflectance but higher loss. The solution is to open up

the closure, use a VFL to find the reflective events and redo

the splices.

POTS

over Fiber

Q: I would like to know if there is information on your

website that explains "POTS OVER FIBER"?

A: POTS - the acronym for “plain old telephone service”

- is digitized to transmit over fiber. In the early days (late

70s and 80s) it was simply T-carrier with a fiber converter.

By the end of hte 80s it was ATM and SONET. More recently,

it’s all going to carrier Ethernet since 99%+ of the traffic

is data not voice or PONs (passive optical networks) for fiber

to the home.

Can I Build A GPON Network

With "Taps"?

Q: Can I build a GPON network where I do a drop to one

subscriber then continue to the next subscriber for another

drop and so on?

A: There have been examples of this type of “tap” drop

proposed, for example in rural areas for drops to

widespread subscribers on a longer network than is typical for

FTTH. It’s just a version of a cascaded splitter network. with

taps that just do a 2 way split. The taps used are typically

90/10 taps, where 10% of the power is tapped off for the drop.

There are some important issues to consider - Since you are

dropping 10% of the power at each tap, you are limited by how

many drops you can have. If you calculate the loss

budget - after the first tap, you have 90% power left less the

excess loss of the splitter (~0.3-0.5dB). The tap power is

down ~10.3 dB and the through power is down ~0.6 dB. At the

next tap, you use the same formula plus you add the loss

of the fiber to that tap and so on until you reach the GPON

limit. It’s a pretty complicated process to design, but

you can see that with these power losses you will not get a

large number of drops in a GPON network with 28dB max power

budget. We did a rough calculation and 20-24 drops may be

possible depending on the fiber lengths.

This network will probably be much more expensive and more

distance limited than simply running a cable with many fibers

and dropping fibers from that cable with midspan entry.

Couplers are expensive, fiber is cheap. We also do not know

the issues with the large differences in transmission times

between the first connections and the last ones, which depends

on the length of fiber in the systems. That may require some

programming at the OLT.

Do

We Need Repeaters For 30 Mile Link?

Q: I need to design a 30 mile (~50km) link. Will regeneration

like a fiber amplifier be necessary?

A: It depends on the comms equipment but I doubt you need

regeneration. 30 miles is 50km, only 10dB of loss for the

fiber at 1550nm, maybe 10 splices at <0.1dB adds only 1dB

loss and another dB for connectors on each end. I think you

probably can find equipment that runs on 12dB loss budget.

That said, most new high speed systems (>10G) have 20km

versions then go to expensive long haul coherent systems. So

talk to the communications equipment manufacturers and see

what they say. If you do need a EDFA, they are not that

expensive but the site is expensive and requires power (+

backup). See if it’s possible to put the EDFA in the end

facilities to get enough power for the whole run.

Connecting

WiFi Access Points In a Passive Optical LAN

Q:

If we install GPON passive fiber optical LAN in a new hotel,

would one need to run fiber to every AP? Since every hotel room

needs an AP this gets expensive. Any suggestion on the simplest

and less expensive way of connecting Fiber Cable to an AP

in the hotel room?

A: You do

not need a fiber to every wireless AP in a GPON passive optical

LAN (POL). The AP needs a UTP (Cat 5e/6) cable with Gigabit

Ethernet and POE (Power over Ethernet) capability. The POL

fiber should terminate in a multiport switch that has a

fiber input and then 4 or more UTP/POE outputs for the wirelses

APs. That’s the cost saving architecture of a GPON POL. See this

page in the FOA Guide:

http://www.thefoa.org/tech/ref/appln/OLAN-POL.html

You should

also check out the APOLAN website (http://www.apolanglobal.org)

for more information on hospitality applications with POLs.

Wireless

Infrastructure

Q:

I am wondering how the landscape will change as the nation moves

from 4G-LTE to 5G. Will it use the same network as currently, or

will the network need to be updated or replaced? To what extent

will 5G be dependent on wireless vs fibre optic? Will the

infrastructure nationally move more toward an underground wired

one, rather than a Radio Access Network?

A: The

wireless network is totally dependent on fiber optics for it’s

communications backbone. The “wireless” part is the connection

from an antenna to the mobile device. From that point, the

network is cabled, mostly fiber already and soon to be all

fiber.

4G/LTE and

soon 5G in urban areas is moving to “small cells” with about 10X

as many cell sites covering much smaller areas. Every small cell

site needs a couple of fibers. Metro backbones will require very

much larger fiber counts, especially with C-RAN (centralized

radio access network) architectures now being implemented.

An example

is Santa Monic, CA where we live. It has about 200K citizens,

8.9 square miles(about 23 sq km), but has planned for 600 small

cell sites, spread over multiple service providers.

At FOA we

see wireless as one of the most active areas for fiber, along

with data centers.See http://www.thefoa.org/tech/ref/appln/wireless.html

Fiber

Ports Or Media Converters?

Q: Should I Buy A Switch With Fiber Ports Or Use

Media Converters?

A: I’m assuming you

are thinking of using a switch with copper Ethernet ports and

a media converter instead of a switch with fiber ports. The

downside is that it adds complexity and increases the chance

of failure. My analogy is something my primary flight

instructor told me many years ago - multiengine planes are not

safer because having two engines doubles your chance of having

an engine failure. IBM still says that most network problems

are cabling problems. Using media converters adds more

electronics, more power supples and more cabling connections.

Passive

OLANs in Hotels And Resorts

Q: Are passive OLANs a good choice for hotels or

resorts?

A: Passive Optical

LANs are enterprise networks based on fiber to the home (FTTH)

technology not Ethernet over structured cabling. The FTTH

network is usually using GPON standard equipment over one

singlemode fiber with passive optical splitters that provides

basic Level 1 and 2 network functionality. This is not

Ethernet but carries Ethernet over the GPON protocols at 2.5G

downstream and 1.25G upstream.

Passive OLANs offer several advantages over conventional

Ethernet switches and structured cabling, including much less

cost (~50% capital expense and ~20% operating expense),

much lower space requirements (see the link to the library

photos below and note the two racks of equipment that support

4000 drops), longer distance requirements (to 20km), easy

expansion (these are systems designed for hundreds of

thousands of users) and easy management (when you have

hundreds of thousands of users, that’s important.)

For hotels, convention centers and similar facilities, the

ease of upgrading to a passive OLAN is a big advantage - one

fiber goes from the computer room to a splitter where it can

serve 32 switches of 4 ports each. That’s right, one fiber can

support 128 users! It can support anything that a network can

- wireless access points, security cameras, secure entry

systems, VoIP phones or POTS phones - anything that will run

over a conventional network.

Duplex

Communications Over One Fiber

Q: Is true duplex over a single fiber possible, or is

more like a shared time-domain technique in a quasi-duplex

mode? I would guess that true duplex would lead to

interference problems.

A. Bidirectional links

are widely used - that’s how FTTH PONs work. They use

splitters to combine/split the signals and one wavelength

downstream and another upstream. See Fiber

Optic Datalinks and for FTTH FTTH

Architectures.

Installation

Fiber Optic Color Codes Reference Chart

Q: Has anyone made a fiber optic pocket reference chart that has cable

color orders, frequencies, or other commonly used info on it?

A: The FOA has a page on its Online Guide that covers color codes

(https://foa.org/tech/ColCodes.htm). It is the most popular page in the

FOA Guide! It works great with a smartphone.

Where

In The US Do Contractors Need Licenses For Fiber Optics?

We often

get asked where in the US do contractors doing fiber optic

installations need licenses. We found a good website for that

information, the NECA -NEIS website. You might remember

NECA-EIS, as they are the partner with the FOA in the NECA/FOA

301 Fiber Optic Installation Standard. NECA is the National

Electrical Contractors Association and NEIS stands for National

Electrical Installation Standards. They have a very easy to use

map and table that gives you data on every state in the US, so

mark these pages for future reference.

NECA/NEIS

http://www.neca-neis.org

(See “State Regulations”)

http://www.neca-neis.org/state/index.cfm?fa=state_regs

(all electrical licensing)

Low Voltage: http://www.neca-neis.org/state/index.cfm?fa=specialty_licensing

Good

Technical Website For Installers

American

Polywater (http://www.polywater.com/)

has one of the best technical website for cable installers. Check

out their website, especially “Videos,” “Engineer’s Corner”

and “Calculators.” http://www.polywater.com/NNNBSL.pdf

Underground Utilities Location

Q: From an OSP engineer: Is there a resource for

underground utilities that we could use on our engineering designs? I

know some counties offer this info but is there a single resource for

all?

A: If you are in the US, the Common Ground Alliance (https://commongroundalliance.com , https://commongroundalliance.com/Tools-Resources/Resources-Library/Toolkits)

is a resource for designers and contractors looking for information on

underground utilities. Their “CGA Best Practices”

(https://bestpractices.commongroundalliance.com) is the best reference

for damage prevention.

Otherwise, the local authorities and utilities are the best source. The

department that issues permits is usually the place to start.

Even with that information, it is recommended that the contractor do

their own search using underground locating equipment before digging.

You may find this page in the FOA Guide on underground cable construction useful. ( https://www.foa.org/tech/ref/OSP_Construction/Underground_Construction.html )

Fiber

Optic Safety Poster

We've had numerous requests to reprint our guidelines

on safety when working with fiber optics, so we have

created a "Safety Poster" for you to print and post in your

classroom, worksite, etc. We suggest giving a copy to every

student and installer.

Splicing Pigtails On A Cable

Q: I seem to be having an issue finding fiber protection sleeves

that can slide over the 3mm patch cable. I bought a sleeve that said it

with made for “single fiber fusion” but the thru hole which I would

side the cable thru prior to fusion is too small for the patch cable.

When I try and look on-line for specifications for the thru-hole size,

prior to fusion final melting of the glue in the sleeve, all I find are

post-melting diameters, none which are even close to being able to

handle the 3mm patch cable.

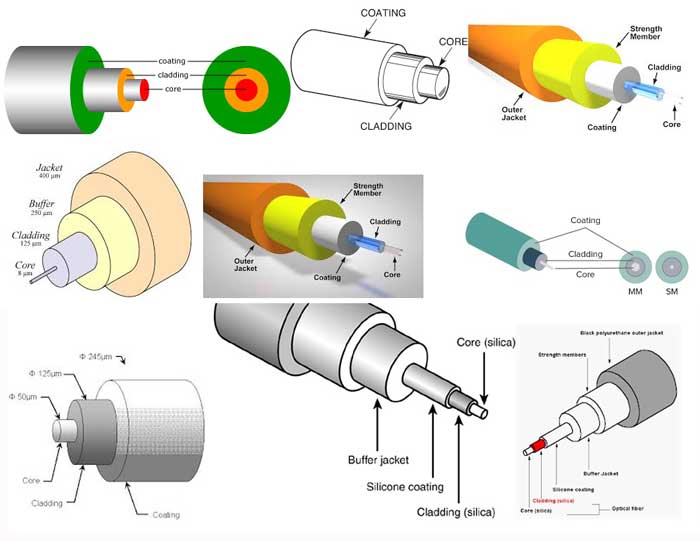

A: Splicing pigtails involves splicing the fibers only and the

cables are secured separately. The usual method of splicing on pigtails

is to splice the fibers and use the heat shrink tube to seal the splice

and the fibers from the outside air and protect it from stress. The

splice is placed in a splice tray. On either side, there is 2-3 feet of

fiber exposed from the cables being spliced. The splice tray has clamps

for all of the cables being spliced on the edges of the tray and the

fiber to the splice is coiled neatly on the splice tray. The jacket of

the pigtail is clamped at the edge of the splice tray but ends there,

so only fiber is coiled in the tray. If you try to coil fiber, the bulk

of the cable can get to be a problem where it’s coiled with the bare

fiber. You can get heat shrink protectors for fibers of 250 to 900 micron diameter buffers, but not for jacketed cables.

Gel Leaking From cables

Q: We have several instances where gel from inside

the fiber optic cable has leaked into the splice closure. I have seen

some information about sealing the ends of cables so that this doesn’t

happen but cannot find a specific method or procedure for this or what

to use for a sealant. Is this something that is common practice for

outside plant cables? The gel creates a mess and definitely makes

reentry for additional splicing more difficult. If there is a way to

prevent or minimize this I would like our technicians to start

implementing it.

A: When you install the cable, after inserting the cable

in the splice closure and/or the budder tubes in the splice trays, seal

the end with silicone RTV adhesive. It needs some time to cure but that

should prevent the gel leakage. Or next time, order dry water blocked

cable which will not have this problem.

Interpreting Customer Spec For Cable Plant Loss

Q: I am currently being challenged by my

customer on some testing parameters and was wondering if I can

receive your input regarding the EIA/TIA-598B standard.

A: The customer spec: l. Rated attenuation: 0.35dB/km and 0.25dB/km at 1310nm and 1550nm, respectively

As we read the customer spec, this section “L” below refers to the

cabled fiber attenuation coefficient of the cable as supplied to the

contractor, not the installed fiber after splicing and termination.

Thses are typical specifications for today’s high quality fiber. It is

also slightly lower than specifications noted in most standards today,

e.g. 0.4 dB/km at 1310 nm is more common. See https://foa.org/tech/ref/basic/fiber.html in the table at the bottom of the page, noting OS!/G.652 fiber specs.

After installation, splicing and termination, the total loss of a fiber

link includes the losses from splicing and termination, plus any passive

devices like PON splitters that may be installed in the link. When

calculating the loss budget (https://foa.org/tech/lossbudg.htm) to

compare to actual test test results, splices may be calculated at

0.15-0.3 dB each and connectors at 0.3-0.75 dB each, adding to the end

to end loss and affecting the calculation of dB/km.

For example, 10km fiber with 4 splices and two connections (the ends) would have a total loss of:

Fiber: 10 km @ 0.35 dB/km = 3.5 dB

Splices: 4 @ 0.15 dB each = 0.6 dB

Connections: 2 @ 0.3 dB each = 0.6 dB

Total link loss = 4.7 dB

If you calculate dB/km for the installed link, it becomes 0.47 dB/km,

even though we used the lowest loss specs for splices and connections.

As stated above, the spec you called out refers to the cabled fiber only

and should be verified by the test documentation supplied by the

manufacturer on the reel.

The loss of the installed link should be calculated in the loss budget

for the link as designed using the given fiber spec plus reasonable

specs for splice and connection loss.

Testing should be done with a light source and power meter (OLTS) and a second test with an OTDR per OFSPT-7 or FOA Standard FOA-1 (OLTS) and FOA Standard FOA-4 (OTDR).

Underground Utilities Location

Q: From an OSP engineer: Is there a resource for

underground utilities that we could use on our engineering designs? I

know some counties offer this info but is there a single resource for

all?

A: If you are in the US, the Common Ground Alliance (https://commongroundalliance.com , https://commongroundalliance.com/Tools-Resources/Resources-Library/Toolkits)

is a resource for designers and contractors looking for information on

underground utilities. Their “CGA Best Practices”

(https://bestpractices.commongroundalliance.com) is the best reference

for damage prevention.

Otherwise, the local authorities and utilities are the best source. The

department that issues permits is usually the place to start.

Even with that information, it is recommended that the contractor do

their own search using underground locating equipment before digging.

You may find this page in the FOA Guide on underground cable construction useful. ( https://www.foa.org/tech/ref/OSP_Construction/Underground_Construction.html )

Markers Required For Underground Fiber Optic Cables?

Q: Are signs required for underground cables like fiber

optic cables? Are they required to have signage so people don’t dig them

up or damage them?

A: In the US the answer is NO. There is no Federal or State law

which requires marking anything other than hazardous liquids and gases.

It is purely a business decision or a moral decision to invest in

signs/markers to protect buried fiber. If a fiber gets cut it can

disrupt 911 service and all kinds of vital communication related to

hospitals, air traffic control, etc.

Distances Between Manholes

Q: What is the standard or max distance between manholes and handholes for fiber optic cable?

A: There are no hard rules, but the distances are determined by a

number of factors. In populated areas, the manholes or handholes would

be situated where you need drops line in front of a building or a

splitter pint for FTTH or conversion from underground to aerial or

underwater cables. From a viewpoint of how far you can go, it’s

determined by: 1. The length of cable on the reel (typically ~5km max,

maybe further for smaller cables, shorter for higher fiber count

cables. 2. The type of the duct, cable and method of installation

for underground. That includes the type of duct, lubricant used, the

number of corners passed, pulling equipment (pulled or blown) and

the tupe of cable - most limited to 600 pound tension. Cable

manufacturers and American Polywater (lubricants) are good sources of

information here. 3. Aerial cable can have quite long spans, esp. using

the moving reel method, which can be limited by the length on the spool.

Gloves

for Fiber Techs

Q:

I was wondering if as part of the safety rules, in addition to

glasses, if it is recommended to use gloves.

If that the case, would you recommend a specific type of

gloves.

A: FOA

emphasizes the need for safety glasses because of the problem

with fiber scraps flying around, especially when students in

class are learning to strip fibers. Proper safety glasses have

side shields that provide more protection than regular

eyeglasses. For eyeglass wearers, prescription safety glasses

are available at very reasonable costs that are much more

comfortable to wear than wearing safety glasses over the

user’s prescription eyeglasses.

We only recommend gloves when working with cables that have

sharp metallic armor in them or some heavy outside plant

cable. The metallic armor can cause serious cuts if one slips

when splitting or removing it. The gloves to use are the

kevlar gloves used to prevent cuts (they are also used for

chefs working with sharp knives.)

Once the cable is opened and you are dealing with buffer tubes

or bare fibers, gloves like the ones used for cables can make

the work difficult because gloved hands are clumsy. Tight

surgical rubber gloves might work for some, but still make

working with bare fiber difficult and provide limited

protection. There we recommend bare hands and being very

cautious.

Height

Of Aerial Fiber Optic Cables

Q:

Is there a code standard for how high from the ground a for a

fiber optic cable running through a residential yard? if yes,

please provide the standard or point me to the standard.

A:

If we go by NEC 2020, the height is 8 feet,above roofs. with

this qualifier. No driveways just over grass. Art

/section 770.44 B. Also 800.44 A 4 states 12 inches between

electric service and Fiber optic cable. But service has to be

12 feet at house so I would say 11 feet above grass. If

driveway is there, Residential 15 feet for service,

electrical, so fiber at 14 feet.

Seal

End Of Cable

Q: For

aerial OSP cable, are there any problems with leaving the end

of the cable open or should it always be put into a closure of

some kind?

A: The

open end of the cable allows moisture to get into the cable

and can be a problem.

I see several scenarios here. If the cable is installed and

waiting for splicing, it could be a matter of time. If the

work is to be done soon - a week or two - leaving it open is

OK, but if the time is longer or you prefer being careful,

just seal the end of the cable by wrapping it with plastic

electrical tape. The end will be opened up for splicing;

about 2m of cable needs to be stripped to splice it, so a few

days exposure is OK, but long term we’d recommend a simple

tape seal, the way manufacturers do when shipping cable on a

reel.

Installing

Cable

Q: Below

are specs for an installation. We’ve never installed a Fiber

Optic run this long. Please see below questions and info.

-Fiber Optic cable to be used is a 24 strand Single Mode

application

-Length of run is 7200 m long

-Appears that all the Fiber is on one reel. However do you

recommend having some junction points on pedestals along the

way for testing-maintenance purposes or just one continuous

run if possible?

A: FOA

has lots of information to help answer your questions:

Re underground installation. See https://foa.org/tech/ref/OSP_Construction/Underground_Construction.html

and https://foa.org/tech/ref/OSP_Construction/Underground_Installation.html

in the FOA Guide.

There are other questions you need to ask:

Are there no intermediate connections or drops required? It’s

just one straight fiber run? You should be able to install it

continuously.

What is the installation type? Pulled in conduit or direct

burial?

If pulled in conduit and you can pull in one try, that’s best.

You should use a pulling capstan to limit tension, attached to

the cable with a breakaway swivel pulling eye and use

lubrication. Use the American Polywater guides (https://www.polywater.com/product/polywater-f-fiber-optic-pulling-lubricant/)

for choosing lubricant and decide if you need an intermediate

pull.

Direct burial is simple for a long run, just ensure you have

the proper equipment.

October

2020's Newsletter article about the installation

of a 6912 fiber cable in small conduit prompted a number

of this month's questions on social media. And there were more

too.

Re: Installation

of a 6912 fiber cable

Q: For

this post, "Tight Fit: 6912 Fiber Cable Pulled in 1.25 inch

Conduit”, he asks if they can see one end completely terminated?

A: It takes about 2 full racks of patch panels or one

rack of splice trays. Sumitomo shows the splicing rack here

https://global-sei.com/data-center-solutions/splicing-rack.html.

Most systems using these cables will buy fully populated patch

panel racks with a splice rack for the cable to splice to 6912

fibers terminated in the rack.

Q: And a second question:: How long does it take to

terminate? And over how many panels?

A: A very experienced tech can splice one of these

cables in ~75-100 hours using ribbon splicing.

Q: I assume that's smaller fiber like 80 micron cladding

A: All the fibers in the high fiber count cables are made

with regular singlemode fiber - 9/125micron. TO make the cables

smaller, the buffer coating diameter is reduced to ~200microns

to make the fibers smaller.

Q: How was it prepared with the splice tray and ODF? It

might require a dedicated panel and splice tray.

A: It takes about 2 full racks of patch panels or one

rack of splice trays. Most systems using these cables will buy

fully populated patch panel racks with a splice rack for the

cable to splice to 6912 fibers terminated in the rack.

Q: Is this an actual photo or was the cable installed in

a different type conduit.

A: We were told that is the actual size of the cable and

conduit although not of the actual installation discussed.

Q: What is the minimum bend radius of that cable? What

procedures did they use to maintain that bend radius through

those 90 degree curves?

A: The minimum bend radius is 15X the cable diameter for

that cable (diameter 1.14” or 29mm), about 17” or 435mm.

The conduit bends had to be controlled to be larger than that

radius. See the Fiber U MiniCourse Fiber

Optic Cable Bend Radius

Preparing

Cable For Splicing

Q: Is

there any standard on the preparation length of strip jacket

upto the splice tray. Ideally its better to have a loop of

buffer before getting into the tray if ever the closure has

enough space for slack.. its also nice to put some hose to the

buffer to add on protection. So far, i don't see any standard

and can't support the remarks on what to follow. The practice

was to take note on macrobend and have enough length of fiber

to reach the machine.

A: There

is a lot of variation in the size, shape and design of splice

closures, so the length varies according to the closure and

trays. For loose tube cable, the length of buffer tube from

the entrance to the splice tray and the length of fiber needed

in the tray are given in the directions for that splice tray.

Similarly for ribbon cable, but the variations in ribbon cable

designs often requires special handling and sleeving for the

ribbons. Most manufacturers have specs available online.

Fiber Splicing Cost

Q: What is the standard of costing for fiber splicing and

terminations? Is it per core / per splice or per each cable end

irrespective of the number of cores?

A: That is a very hard question to answer, other than to say ”it

depends. ” The number of fibers is definitely a factor because each

fiber must be stripped, cleaned, cleaved and spliced then placed in the

splice tray.

It also depends on:

- Single fiber or ribbon splicing?

- Type of splice closure

- Type of cable (loose tube, ribbon, flexible ribbon, high density, armored, ADSS, etc.)

- Installation: aerial or underground

- Location: urban or rural

- Set up time (same for low fiber count cable as high fiber count cable)

Most contracts will be considering the number of

fibers but also these factors, and probably they want to price by the

number of fibers, but the price per splice will vary accordingly. We've

seen quotes in the US for prices varying over a 10X range.

Lashing

Aerial Cable With Cable Ties?

Q: I am considering an electrical job installing fiber

optic aerially on a messenger cable.

I have seen the cable tie method of lashing the fiber to the

messenger. Would you recommend this method considering the

cost of a lashing machine for a single project and if so what

would be a good distance between ties for the proper support

of the fiber to the cable.

A: The normal way to attach an aerial cable to a

messenger is lashing the cable with stainless steel wire. If

you use cable ties, you would need ensure the cable doesn’t

droop and the cable ties are designed for outdoor use in the

sun over a long time (stainless steel ones are available). How

long is the span? If it’s more than 100 feet, I think I would

go with lashing. If you don’t have a lasher, you can rent one.

You will need a bucket truck anyway.

Restoration

Time

Q:

Do you have any statistical data on how long (on average) it

takes for a utility network operator to detect and pinpoint the

exact location of a fiber cut?

A:

We don’t have any information on the average time it would take

to find a fiber fault and like all averages, it might not have a

lot of meaning.

Many

fiber optic links today have alarms that indicate loss of

transmission so they tell you immediately when the link goes

down. Identify the link and the fiber connection. Then it

becomes a matter of troubleshooting and eliminating causes.

Sometimes even when reconnected the equipment requires a system

reset to get started.

First

- check the power on the equipment

Secondly:

determine if someone was doing something in the equipment area

that might have caused a problem. We do know of a link that was

brought down because an executive giving a tour disconnected a

live link to show someone a fiber connector! If someone was

working nearby, check that area first - patchcords, cables, etc.

Don’t forget to check work records to see if a crew is working

around the cable plant at that time. It’s possible a crew

installing new cables damaged old ones. See the FOA newsletter

for this month for what installers do on aerial cable plant

https://www.foa.org/foanl-3-20.html or last month for

underground https://www.foa.org/foanl-2-20.html.

If

it appears to be in the cable plant and nobody is working near

it, OTDRs are generally used for troubleshooting. They get you

into the area where the problem is and them it’s finding it

manually. Underground it’s often contractors digging or boring,

overhead it’s just poor workmanship - or as a guy from

Bonneville Power put it, it may be “target practice” although

animals damage aerial cables too.

FOA

has a page on restoration

https://foa.org/tech/ref/restoration/rest.html and some of our

instructors do seminars on it.

Time?

If there are trained techs available, finding the problem can

take less than an hour. If not, it can take a lot longer. Repair

can be hours or days if the proper techs and equipment are not

available.

If

nonstop service is required, alternative fiber routing is the

solution - build a mesh network.

Under

any circumstances, having a restoration plan and repair

materials should be ready. If tech personnel are not available,

a contractor on call is needed.

Cable

Installation Guidelines

Q: I am trying to find information on the

recommendations regarding fiber underground in conduit. I am

looking for industry specific verbiage on the cumulative turn

degrees before you need a handhole or manhole. I believe it is

180 degree cumulative but I can’t find it anywhere.

A: We’ve heard the 180 degree limit mentioned on some

conduit but not for fiber optics. For any fiber optic cable

pulling, the relevant issues are pulling tension and bend

radius.

We know of no specific standards or guidelines on conduit

bends for fiber optics. It has many factors, including conduit

size and type - there are many types, length of the pull,

radius of the bends, type of fiber optic cable and lubricants

used, if any. For the cable, there are thousands of fiber

optic cable designs that vary in diameter from ~3mm to ~30mm

depending on the type of cable and number of fibers, the

stiffness of the cable and the location and type of

stiffer/strength members and the method of installation -

pulling or blowing/jetting. And for locations as far North as

you are, temperature can be an issue as cable gets stiffer

when colder!

For any given installation, corners are generally accommodated

by handholes/manholes and pulling done from handhole to

handhole with figure-8ed cable pulling techniques to prevent

cable damage by excessive tension or bending.

FOA has a section of our Guide on OSP construction: Outside

Plant Fiber Optic Cable Plant Construction and in that

is a section on OSP

installation. For specific cables or conduit runs, we’d

suggest talking to the application engineers at cable

manufacturers who can give specific advice.

Construction

Near Underground Fiber

Q: What is the recommended distance for any new building

construction to build near underground fiber duct channel?

A: We do not know of any standards or codes related to

construction near fiber or other underground utilities. Common

sense dictates that one stay far enough away to prevent

accidental damage, so adding 5-6 meters(15-20ft) from the

areas of construction makes sense.

Pulling

Cable

Q: I’m having trouble finding much information on the

matter. What type of swivel should be used to pull fiber and

what would be the correct way to pull armored fiber.

A: Start on the FOA Guide here and go here for

types of swivel pulling eyes. with https://foa.org/tech/ref/OSP_Construction/Underground_Installation.html

and here are sources https://www.comstarsupply.com/cable-pulling/swivels.html

It’s not common to “pull” armored cable since it’s designed

for direct burial, but a kellums

grip on the jacket will generally work.

Communications

Cables on Utiity Poles

Q:

Is there a standard that service providers such as ISP, FTTH

or cable TV should follow when installing their cables on

existing electric poles. For necessary clearances etc. ?

A: The location of comms cables is in the

“Communications Space.” At the top of the pole is the “Supply

Space” for power conductors and between the two is a “Safety

Zone Space.” It is There are guidelines of various types,

mostly referring to NESC Rule 235. One of the best documents

on this is from Nashville

Electrical Service. This presentation

from Finley Engineering offers a good summary.

"Snowshoes" On Aerial Cable

Q: For

overhead installation, can snow shoes, or other service

loop devices, hold two separate cables?

A: Snowshoes are sized for

different cable sizes and types. Some snowshoes are big

enough for several cables, that’s no problems.

Fiber

and Power Sharing Conduit

Q: We are working on a project that has miles

of underground 7 cell innerduct conduit with existing fiber

already running through one of the cells. Is it possible to

run electrical conductors through the 2 of the other cells?

The conductors would be no larger than 1/0 AWG at 480V or

600V. Both the fiber and the electrical are being installed

for the same use.

A:We questioned several people in the electrical side

that also do fiber work. The opinion is that the electrical

may use the other ducts. If the fiber cable has conductive

members, e.g. armor, it must be properly grounded. And any

cables spliced in manholes need separation and marking. The

concern is over what happens with a dig up, but as long as the

electrical is turned off before restoration begins, there

should be no problem.

Fan-Out

Kits Needed?

Q:I’m

working on some MM fiber and am unsure if I need a fan out

kit. Is there a way I can tell if I do?

A:

Is it 250 micron or 900 micron buffer? Splicing or

termination? Loose tube or tight buffer cable? Generally

loose tube cable with 250 micron fiber needs no fan out

kit for splicing - tubes go to splice tray and bare fibers

are protected in the tray - but probably needs it to

terminate if the fibers are exposed, for eample with SOCs

- splice on connectors. Tight buffer - 900 micron fiber -

does not need fan out kits.

Pull ADSS Cable In Ducts Underground?

Q: Our city is installing a 1.5 mile run, mostly

aerial and we want to use ADSS cable. There are two or three

road crossings where we want to go underground in conduit

installed by directional boring. Can the ADSS cable be

dead-ended, brought to the ground, figure-8ed and pulled

through conduit then continue the aerial installation?

A: The answer is yes this is not an issue and is done

all the time. It is standard procedure. (Thanks to Pat

Dobbins, FOA, the expert on ADSS cables.)

Microtrenching

Q: I recently read an article you wrote in April of

last year about micro trenching..Currently, I am employed

with an underground construction company. Something we have

never been involved with is micro trenching and would like

to possibly get some equipment and training scheduled in the

near future. In saying that, it has seemed to be almost

impossible to find numbers on the price per foot.

Essentially, I am asking if you have any resources to some

up with those numbers or models to maybe use for pricing

purposes.

A: Microtrenching is becoming another tool that

contractors are adopting because like directional boring is

is less disruptive than regular underground construction.

I’m working with one group that’s using microtrenching in CA

cities, installing microducts and a 288 fiber

about the size of a #2 pencil. Cost is difficult to

generalize other than “more than aerial and less than

trenching.” Cost is very dependent on where you are

working and what the local geography looks like. We know one

contractor who claimed to do 5 miles a day in rural

Washington at costs near that of aerial. It’s especially

good in areas with lots of base stone where trenching or

boring is near impossible or cluttered utilities downtown.

Here are a couple of pages on the FOA website about

microtrenching:

Outside

Plant Fiber Optic Cable Plant Construction

Underground

Cable Construction

Microtrenching

Ditch Witch sells equipment for trenching and trains users.

Condux has the equipment for blown cable and offers training

several times a year.

Blasting

Near Fiber Optic Cables

Q: We

have a project where blasting is planned near fiber optic

cables. We find no standards for this. Is it safe for the fiber

or should we treat it like other utilities like gas and water?

A:

FOA

recommends considering fiber optic cables to be similar to gas

lines when blasting nearby. We know of no standards for this but

there are some descriptions of projects requiring blasting near

fiber optic cable installations. Here is a pipeline

company's guidelines for blasting. The guidelines seems to

focus on staying 5m from the fiber optic cable and using careful

blasting techniques.

Markers

For Underground Fiber Optic Cables

Q: I have a general question about above ground

markers for fiber optic cable in conduit. Is there a

recommended spacing for the markers? Is there a standard

to reference for this?

A: We asked some people who make them and they said the

guideline is “line of sight.” The rules for markers are

mainly what information needs to be on them. Of course we also

recommend adding marker tape about a foot above the conduit. I

was curious if there were any legal issues and I found this

interesting page from Cornell Law School: https://www.law.cornell.edu/cfr/text/49/192.707

So I might add to line of sight any crossings of

roadways, rail ways and some markers for bridge crossings.

We have a new section on the FOA Guide: Outside

Plant Fiber Optic Cable Plant Construction that may be

useful.

Terminate

All Fibers Or Just Some?

Q:We

are currently running fiber which will be 12/24, my question

is do we need to terminate every pair even if we aren't going

to be using them or is there an alternative?

A: No

you do not need to terminate all of them and leaving some bare

fibers is often done when there is no planned use for the

fibers or to save money. However, there are some other issues

to consider. You do need some spare fibers ready to use,

either in case of problems or for upgrades. For small fiber

counts, the cost of terminating them all at once will be

cheaper than having to come back to the site and doing it in

the future. The economics are quite different if you have 144

or more fibers, of course. If you leave bare fibers, be sure

to leave enough length to terminate or splice later - about a

meter for termination and 2m for splicing. And protect them

from damage so they can be used in the future.

Removing

Old Fiber

Q: I have several 1000 feet of old 62.5/125 armored

fiber optic trunks under a raised floor that I am

replacing/upgrading to 50u MM and SM trunks. Is there any

guidance on ‘Best Practices’ to follow when cutting these

trunks into more manageable lengths for removal?

A:

Use a jaws-type cutter to cut the cable into reasonable

lengths and remove it. There should be no danger in cutting

the cable up as long as your workers only cut the right cable.

Raised floors often have large numbers of cables - often

including power cables - so its important to ensure the proper

cables are being cut an removed.

Re-routing

Old Fiber Optic Cables

Q; I have a questions about the re-routing of fiber

optic lines that have been in place for a number of

years. Is it a standard transaction in the fiber optic

business to have to re-route fiber that has been in service

for a long period of time. (e.g. >20 years) If

so, is there a best practice for removal from conduit for

re-rerouting?

A; There is no way we would recommend removing and

reinstalling 20-year old fiber cable. First of all, old cable

may be damaged in removal. Then cable and fiber technology has

improved over the years so you can get much better components

today at greatly lower prices. (One industry analyst I know

likes to say that fiber is cheaper than kite string and

fishing line!) Today’s cable designs allow for much smaller

cables with many more fibers (288 fibers in 9.7mm - just over

3/8”) and new conduit designs allow for more cables in a

conduit (microducts and cloth ducts) and easier installation -

blowing in cables and microtrenching are perfect for metro

areas.

More fibers, especially in a big city, is a must. Smart

cities, small cells, FTTH (fiber to the home), ITS

(intelligent traffic systems), V2X (vehicle to vehicle,

infrastructure, etc.) and many other services need lots of

fibers.

Our recommendation is to pull it out and dump it. Install new

ducts and the fiber you need (x10 maybe?) and have new ducts

for future use. Are you familiar with “Dig Once”?

Why A Figure 8 Cables?

Q: What is the reason for wrapping the cable in a figure

eight?

A: When you need to do an intermediate pull, you have

to pull the fiber and coil it on the ground. A simple coil

will put a twist in the cable. Figure-8 coils put in twists of

opposite directions on each side of the 8 making for no

overall twist in the cable. See How

To "Figure 8" Cable For Intermediate Pulls in the FOA

Online Guide.

Maintenance

of Fiber Networks

Q: Can you guide me how to prepare Optical Fiber

Cable Annual Maintenance Proposal?

A: Basically, the

network needs to be installed properly, fully tested and

everything carefully documented. Then no routine maintenance

is required. Most problems with fiber optic networks occurs

when techs are working with it, e.g. damaging cables or

getting connectors dirty when testing, so leaving it alone

is the best plan.

Electronic transmission equipment can be tested anytime to

ensure proper data transmission, but that does not involve

accessing the fiber.

We have several things which may be of help:

You Tube Video: FOA

Lecture 39 Maintaining Fiber Optic Networks

Web page: Maintenance

Getting

Old Cables Out Of Conduit

Q: How do you get old cables out of a conduit when

they are stuck?

A: Usually we are concerned about reducing friction

when pulling cables through conduit, but sometimes you need to

get them out. Here

is a page from American Polywater the leading lubricant

company with advice on the subject.

Designations For Fibers

Q: I'm currently working on a project involving optical fiber

with VMS signs, CCTV cameras and other ITS equipment. I was wondering if

there is a standard or a good practice which describe the typical

assignation for each optical fiber on a 6 fibers cable for

example? By that, I mean :

- fibers number 1 and 2 : VMS;

- fibers number 3 and 4 : CCTV;

- fibers number 5 and 6 : spares

A: There are several ways people assign polarity on duplex links.

The way you suggest is the most common I believe. Use the odd number

fibers to transmit in one direction, even number fibers to transmit in

the other direction and document the color codes.

"Mining" Cables In Data Centers (Cable Removal)

Q: Is there any documentation out there on best practices for data center cable mining? Any help would be greatly appreciated.

A: This has been a topic in premises cabling since first

proposed by NFPA for the NEC twenty years ago. FOA has gotten this

kind of question before for many different circumstances, but I must

admit that I know of no recommended procedures or standards for the

removal of abandoned cable.

Cable “mining” often refers to the removal of

underfloor cable, may apply to cables in trays and is hard to get

information online - search for “Cable mining” and you get links to

sellers of cables designed to be installed in mines (coal, salt,

minerals, etc.) underground!

The biggest problem with removing unused cables is

identifying the cables to remove. Underlloor cables are particularly

bad, it seems, since you have generations of abandoned cables, often

poorly marked, sometimes mixed with power cables. With metallic cables,

you can sometimes use an ancient telephone tool, a “toner” to trace

cables, With fiber you just have to be careful that you identify the

cable before you cut.

It’s always better to remove small sections, especially if you can tug

on the cable and verify it each time before cutting. We’ve seen photos

of an early data center with cable trays 2 feet deep by 4 feet wide full

of about 4,000 fiber optic cables. After seeing that you understand why

the new high fiber count cables (1728, 34456 and 6912 fibers) are

desirable!

Why

We Warn You To Be Careful About Fiber Shards

Photo courtesy Brian Brandstetter, Mississauga

Training Consultants

1-844-440-0047

www.fiberoptictraining.com

Fiber/Cable

Fiber Optic Color Codes Reference Chart

Q: Has anyone made a fiber optic pocket reference chart that has cable

color orders, frequencies, or other commonly used info on it?

A: The FOA has a page on its Online Guide that covers color codes

(https://foa.org/tech/ColCodes.htm).

It is the most popular page in the

FOA Guide! It includes a print your own pocket color code chart and one

for your smartphone or tablet - works great with a smartphone.

Multimode

In Premises Cabling

Q:

I wonder when/if single mode fiber will start invading the

enterprise. There's a whole ecosystem, of course, in addition

to physical fiber cabling. Switches, server connections,

protocols, etc. But I'm wondering if you see the industry

moving towards some set of standards using single mode?

A: Today, singlemode transceivers are as cheap as

multimode for 10G and cheaper at higher speeds. Indoor cell

systems (DAS) use singlemode. FTTH PONs (passive optical

networks using singlemode) are being used for LANs because

they are cheaper too. Both technology and costs point to the

advantages of SM. Multimode is the historical design and it's

hard to change. But structured cabling standards (TIA-568, ISO

11801) include singlemode and POLs (passive optical

LANs.)

Storing Fiber Optic Cable On Reels

Q: is there a "standard" for how to store a fiber optic cable reel?

A: This is another detail that has not in my knowledge ever been

included in a standard. However manufacturers usually put a note on the

reel to keep it upright - standing on the edges of the spool sides, not

flat on one side of the spool. If the fiber is to be stored for a

period of time, it should be stored in a cool dry place and the ends

sealed with electrical tape.

(Photo storing cable on reel)

Midspan

Drop Cables

Q: I

am working on a project that has 5 sections, consisting of 5

miles each section, CCTV, detectors, DMS connected by 192

count fiber. We were directed to use the consultants

plans from the first section as a guide for uniformity for the

remaining contracts. The attached fiber detail shows a 4

fiber drop cable going to the ITS device. I was thinking

to take all 12 fibers to the device and back for

redundancy? Also, if we did use the 4 fiber drop cable,

I didn’t understand why they would splice the other 10 thru

cables and instead leave them intact? Is there a preferred

method for a drop cable to a device or just preferences?

A: We are not sure why they do it the way they do.

Perhaps the designer was not familiar with midspan access

which would preclude having to make the other splices. Using a

12 fiber drop cable would be more expensive and perhaps

unnecessary unless the device being connected is in a location

where a small cell site might be located. They may also have

uses for those other fibers that require a connection through

the drop point. We”d suggest to the designer that

midspan access might allow saving the 10 splices at each drop.

Fiber

Flexibility and Longevity

Q:

When I think of glass, I think of a material that is not

very flexible. If you try to bend most glass, it will break.

So it is rather remarkable that you can bend a fiber and

not crack it, even though the strands are quite thin. Perhaps

it's not a good idea to bend fiber too sharply? I was talking

to the people who maintain the fiber network at the university

here. They tell me they have a problem when fiber gets to be

about 15 years old, it will start to become brittle. If you

flex it, it will crack or break. Is this a common problem? How

long can fiber be expected to last before it becomes brittle?

Is fiber that is manufactured more recently have a longer

life-span?

A: Fiber is quite flexible. One demo I did when I taught

classes was to walk up to a large window and push on it,

telling everyone to watch the reflections to see how the glass

flexed. I can flex quite a lot. Like most materials, as it

gets smaller, it can bend more easily because the stress is

less across the cross sectional area. Consider a bar of steel

1” in diameter compared to a piano wire or banjo string. Most

things break because either they are overstressed or there is

some impurity in the material that focuses the stress and the

crack propagates from there. Ever cut glass? You scratch it

and stress it along the scratch line and its maps off - called

cleaving - where the stress concentrates along the induced

fault. Fiber is extremely low in impurities - a matter of how

it’s made from raw materials, not melted sand like most glass

- that’s part of what makes them have such low loss (efficient

transmission) and high strength. A glass fiber is much

stronger than steel of the same size. Corning

explains it here.

The brittleness of older fiber is due to the migration

of moisture up the cable into the glass. The H2O becomes the

OH radical which interacts with the glass to reduce its

strength. Most cable companies say their cable today protects

the fiber well enough that it should last 40 years, but where

fiber is terminated or spliced and exposed to the air, it can

get brittle and be hard to handle in 10 years or more. Older

fiber had shorter lifetimes simply because we learned to make

fiber coatings and cables better at sealing fiber from the

ambient atmosphere.

Fiber

Choice for LANs

Q: Many manufacturers or suppliers worldwide emphasize

the use of OM4 multimode optical fiber for the LAN. Does

single-mode fiber not provide greater bandwidth than

multimode? Do they imply that single mode optical fiber should

only be used for long distance applications and not in LAN

environments?

A: Multimode fiber is acceptable for LANs up to 10

gigabits/second and up to 550 meters depending on the type of

fiber and Ethernet version. See this

page for a complete list of network

specifications.Higher versions of multimode fiber OM2-OM3-OM4

have higher bandwidth capability. OM5 is a version of MO4 that

also supports wavelength division multiplexing with VCSEL

sources in the extended wavelength 850-950nm range. OM1 is a

earlier fiber with a different core size that has not been

designed into new systems for almost 20 years. LANs can use

singlemode fiber for all versions. Singlemode has longer

distance capability (up to 40km) and virtually infinite

bandwidth. See the singlemode specification in the link above.

Singlemode is also used in passive optical LANs that can be

much cheaper to build than conventional networks. See this

page for information on optical LANs (OLANs)

including passive OLANs based on FTTH GPON technology.

Fiber

Lifetime

Q: I am often ask how long the fiber we are deploying

today will last or be useable , I typically say something like

it will last at least 20 years and that no one really knows

how long it can be used. What is the oldest fiber

optic network or longish segment that is still in production

that you know of?

A: Current cables are probably good for 40 years or so.

Today there is some fiber being used by telcos from the late

1980s and lots form the late 1990s and early 2000s. Lots of

OPGW (optical power ground wire) is in use up to 30 years old.